Longitudinal angle rotation mechanism for mechanical arm

A technology of rotating mechanisms and manipulators, applied in the field of manipulators, can solve problems such as simplicity and structure that have not yet been seen, and achieve the effects of convenient manufacturing, concise overall structure, and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

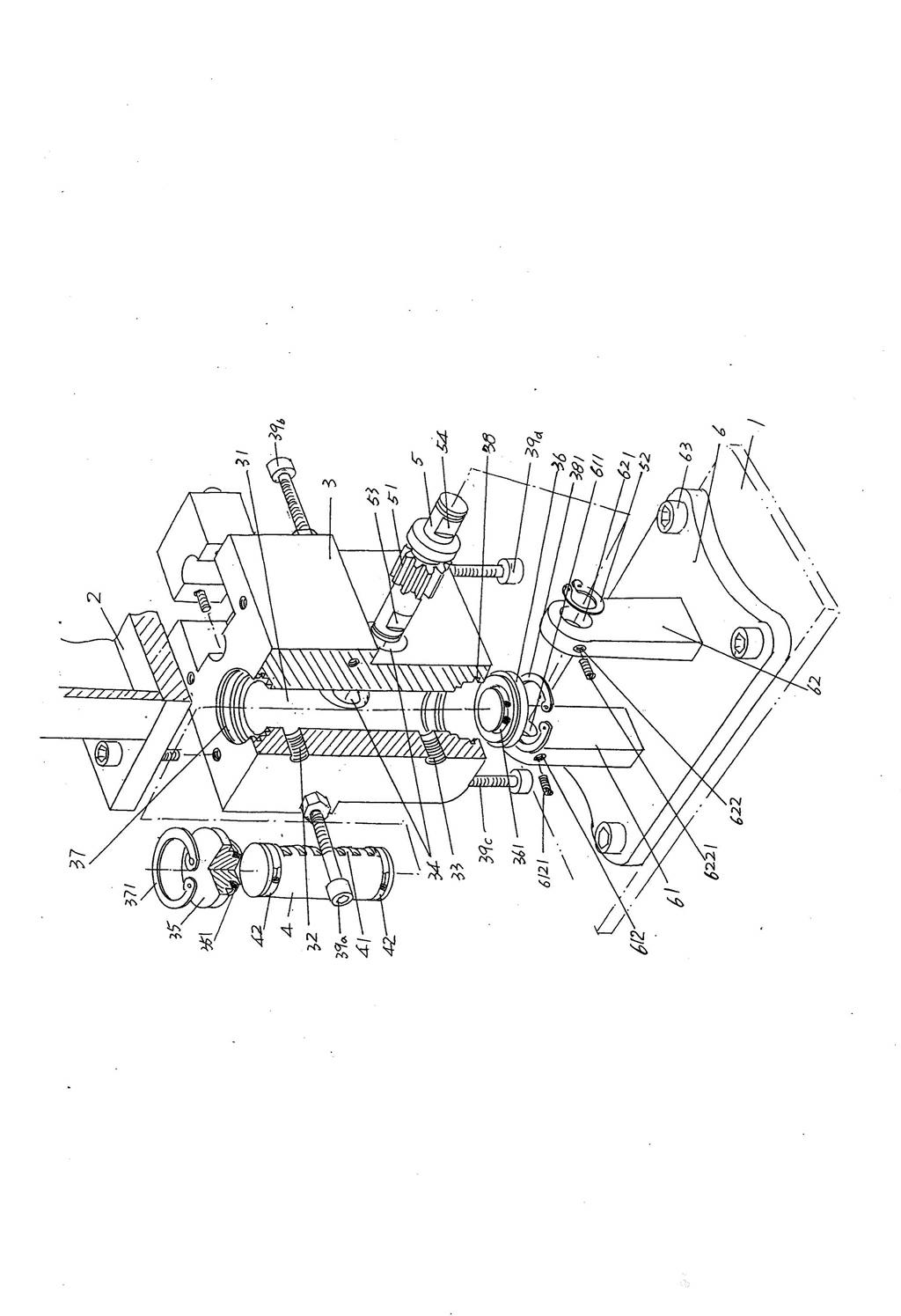

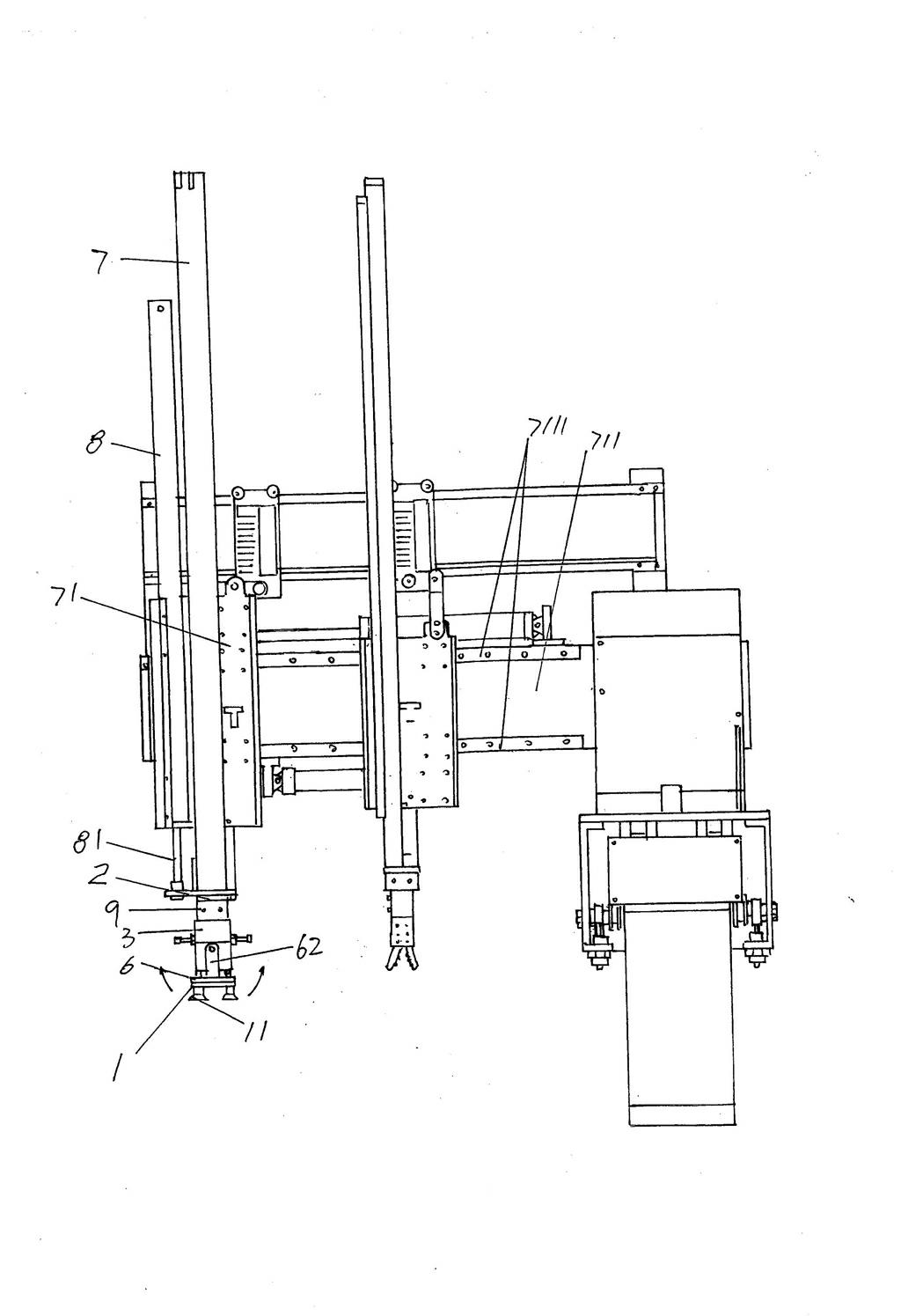

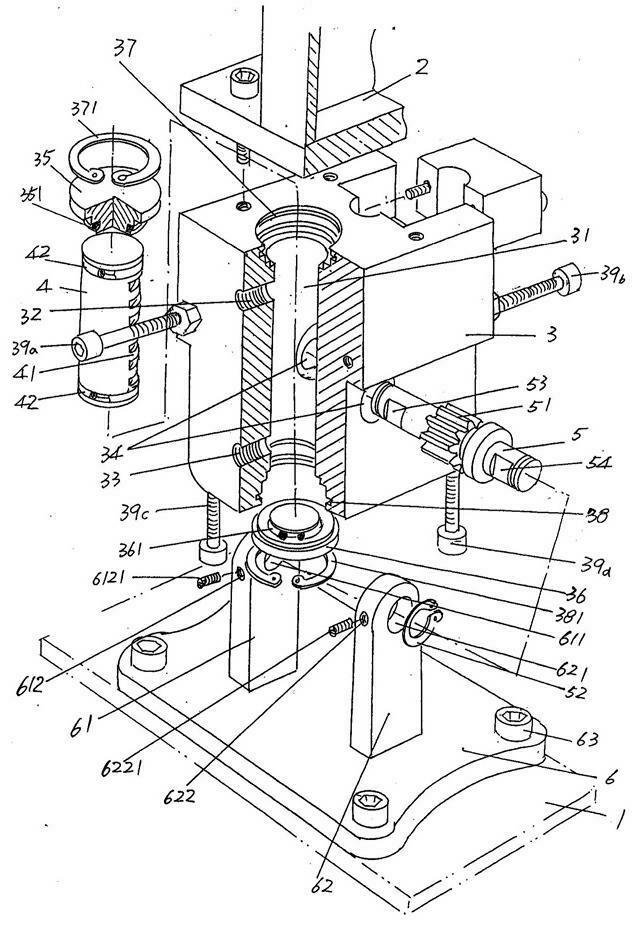

[0021] See figure 1 , the suction cup 1 and the slide bar base 2 of the manipulator are given, and the longitudinal angle rotation mechanism for rotating the suction cup 1 is located between the suction cup 1 and the slide bar base 2 .

[0022] The preferred but not limited longitudinal angular rotation mechanism includes a cylinder block 3, a piston 4, a gear shaft 5 and a rotary seat 6. The cylinder block 3 can also be referred to as a cylinder body (hereinafter the same) through the fixing screw holes provided on it and the fixing screws It is fixed with the aforementioned slider seat 2. The height direction of this cylinder base 3 is processed with a cylinder cavity 31, and one end of the cylinder cavity 31, that is, the upper end of the position shown in the figure, is equipped with a first cylinder head 35, and the other end, that is, the lower end of the position shown in the figure, is equipped with a second cylinder. Cylinder cover 36, and a first limiter groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com