Heat preservation block machine

A technology for insulating blocks and molding machines, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of low production efficiency, low production efficiency, and high labor intensity of workers, and achieve the effect of reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

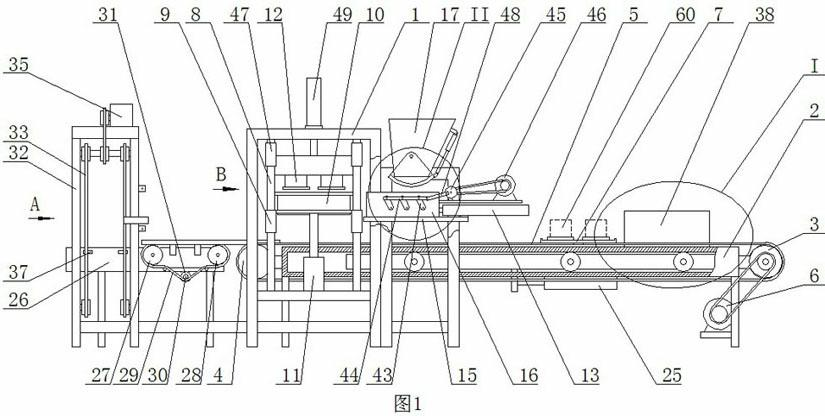

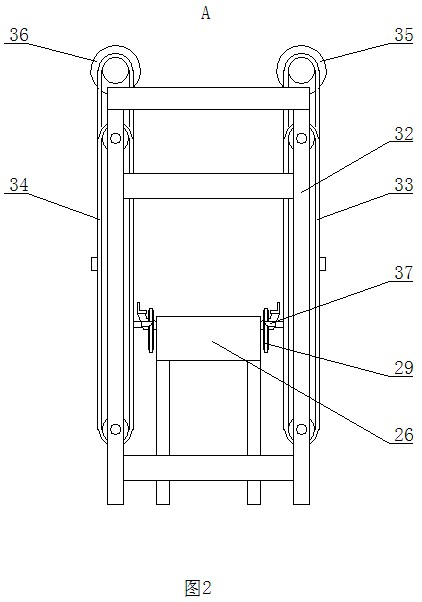

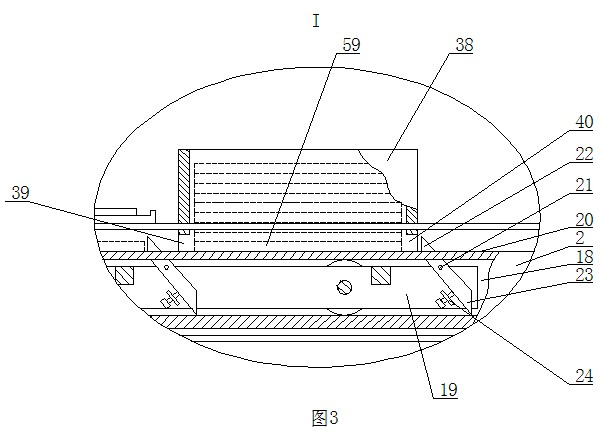

[0007] The thermal insulation block forming machine of the present invention includes a frame 1 and a bottom plate conveying frame 2, the two ends of the length direction of the bottom plate conveying frame 2 are respectively provided with a first sprocket 3 and a second sprocket 4, and the first sprocket 3 and the second sprocket The sprockets 4 are connected by the bottom plate conveying chain 5, the bottom plate 7 is installed on the bottom plate conveying chain 5, the wheel shaft of the first sprocket 3 is connected with the first motor 6, the longitudinal guide column 8 is installed on the frame 1, and the longitudinal guide column 8 The first guide sleeve 9 and the second guide sleeve 47 are installed, the first guide sleeve 9 is connected with the molding die 10, the molding die 10 is provided with a forming groove 14 that penetrates up and down, and the molding die 10 is connected with the movable rod of the first pressure cylinder 11, The second guide sleeve 47 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com