Waterproof roll material automatic leakage prevention fixing device and method for installing waterproof roll material by adopting same

A technology of waterproof coiled material and fixing device, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve the problems of easy water leakage, easy puncture of waterproof board, water leakage, etc., and achieves good effect and tight nail wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

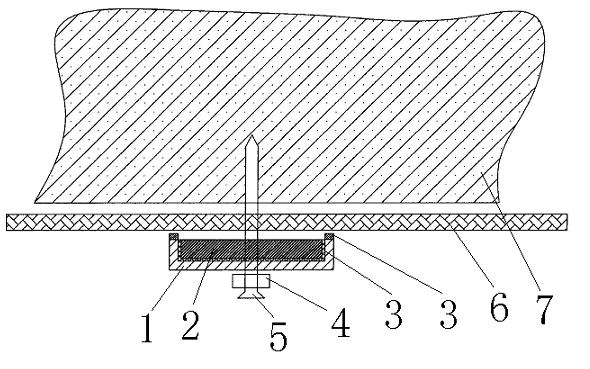

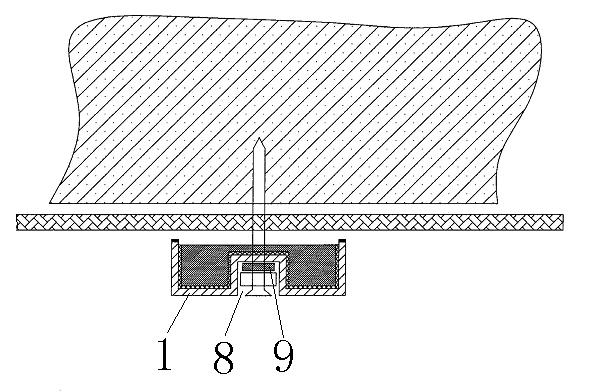

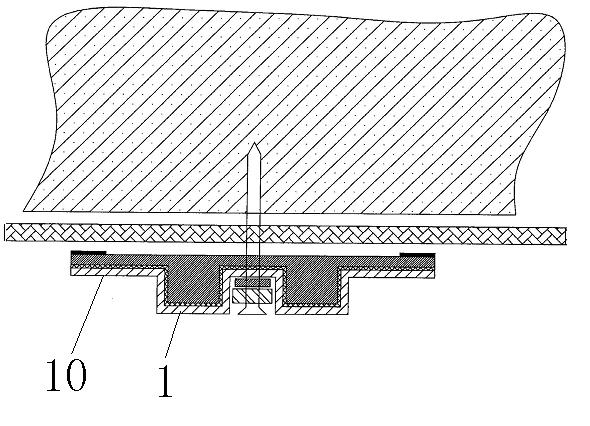

[0020] The structure of the waterproof coiled material automatic leak-proof fixing device provided by the present invention and the method for installing the waterproof coiled material will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the waterproof coiled material automatic leak-proof fixing device of the present invention includes a leak-proof bowl 1, a super-absorbent resin filler or a rubber filler 2 is arranged inside the leak-proof bowl 1, and the inside of the leak-proof bowl 1 and the edge of the leak-proof bowl 1 are arranged There is an adhesive layer 3, and the nail 5 with the positioning collar 4 passes through the anti-leakage bowl 1, the superabsorbent resin filling body or the rubber filling body 2 to fix the waterproof membrane 6 on the base layer 7, and the anti-leakage bowl 1 can be Be circle, oval, triangle, rectangle or polygon. Such as figure 2 As shown, the anti-leakage bowl 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com