Centrifugal compressor having variable geometry diffuser and method thereof

A centrifugal compressor and diffuser technology, applied in non-variable-capacity pumps, machines/engines, components of pumping devices for elastic fluids, etc., can solve problems such as lack of resistance to vibration and achieve easy connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

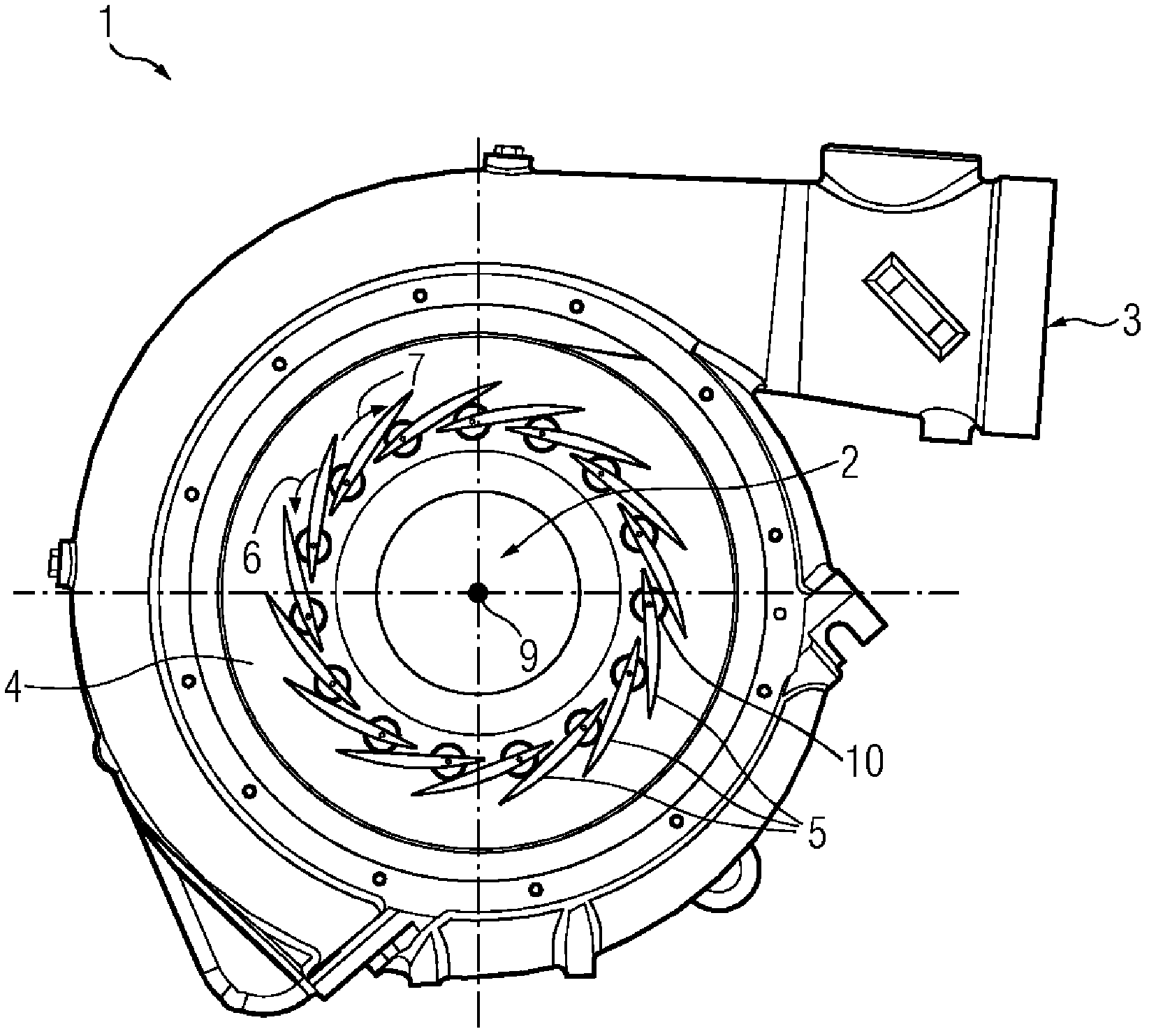

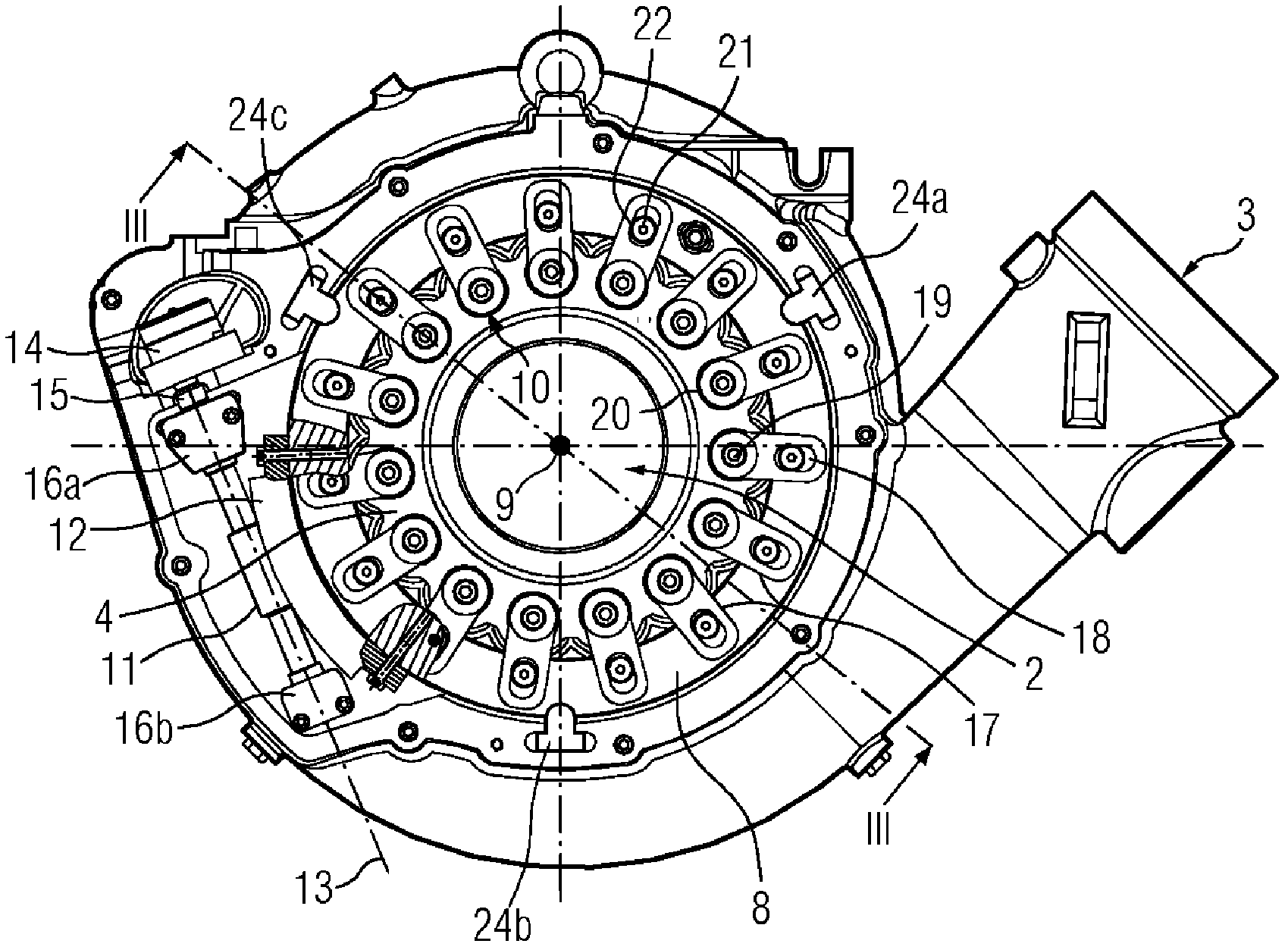

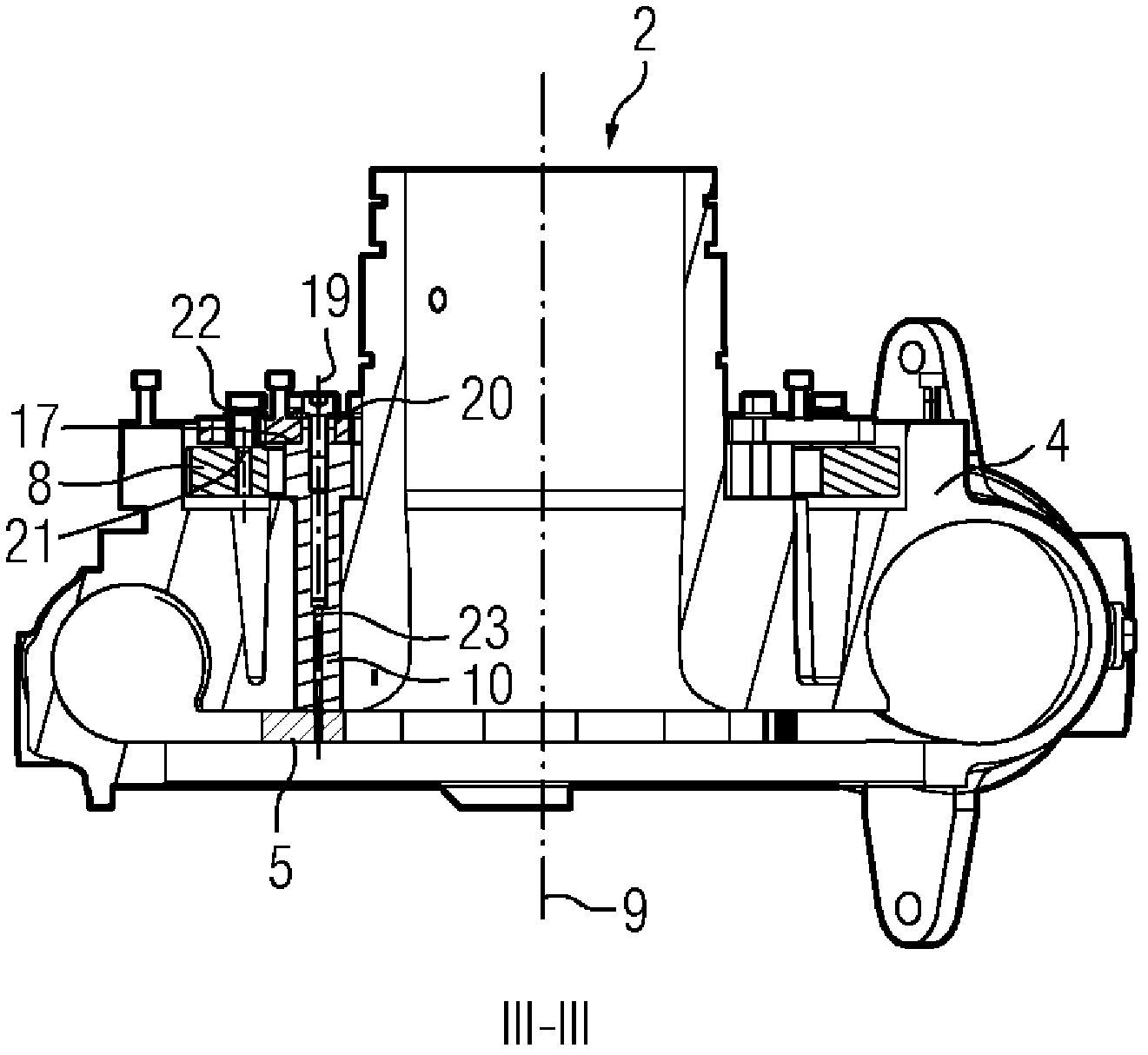

[0018] now refer to figure 1 , figure 1 A rear view of the centrifugal compressor 1 is shown. In operation, compressor 1 receives gas axially through inlet 2 . The gas flowing through the inlet 2 is accelerated by an impeller mounted on a rotor (not shown for clarity), which increases the kinetic energy of the gas. The kinetic energy of the gas is then converted into a pressure increase by diffuser vanes 5 arranged downstream of the impeller. The impeller and diffuser vanes are housed in the volute casing 4 , which direct the gas tangentially flowing from the diffuser towards the compressor outlet 3 .

[0019] The diffuser vanes 5 are arranged in arrays spaced circumferentially around the machine axis 9 . In order to provide a wide operating range, the position of the diffuser vanes 5 can be varied between a maximum volumetric flow setting and a minimum volumetric flow setting. The variable geometry is achieved by pivoting the diffuser vanes 5 to match the discharge angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com