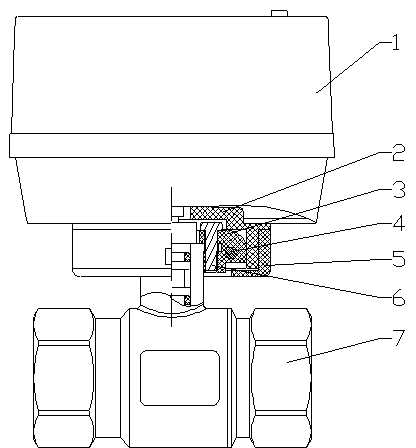

Sealing structure of auto-control valve shell

A self-control valve and self-control valve technology, which is applied in the field of electronic information, can solve the problems of increasing production and maintenance processes, lack of connection and tightening, and the falling of the self-control valve head, and achieves obvious sealing effect, simple appearance and simple assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

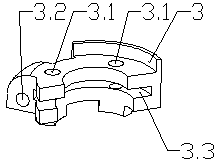

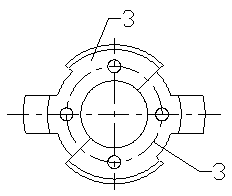

[0021] Embodiment 1. A sealing structure of a self-control valve casing, including a positioning ring 3 , a coupling sleeve 2 , a positioning pin 4 , and a ring 5 .

[0022] The locating ring 3 is used to fix the valve body 7, and has a fixing groove 3.3, a locating hole 3.1, and a pin hole 3.2. The fixing groove 3.3 is a semicircular slot. When the two locating rings 3 are combined and assembled, the valve body 7 will Hold tight, at this time, you can use the screw 6 to penetrate the positioning hole 3.1, and connect the positioning ring 3 with the valve body 7 to increase the structural strength. The pin hole 3.2 is used as a connecting part to connect with the coupling sleeve 2 using the positioning pin 4.

[0023] The coupling sleeve 2 is connected to the self-control valve head 1 through a screw hole 2.3, and its other end includes a cavity 2.1 and a pin hole 2.2. The cavity 2.1 is used to accommodate the positioning ring 3 after assembly, and the pin hole 2.2 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com