S-line direct current permanent magnet motor

A permanent magnet motor and coil technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve problems such as limiting the further improvement of permanent magnet motors, and achieve the effect of high efficiency factor and reduced copper consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

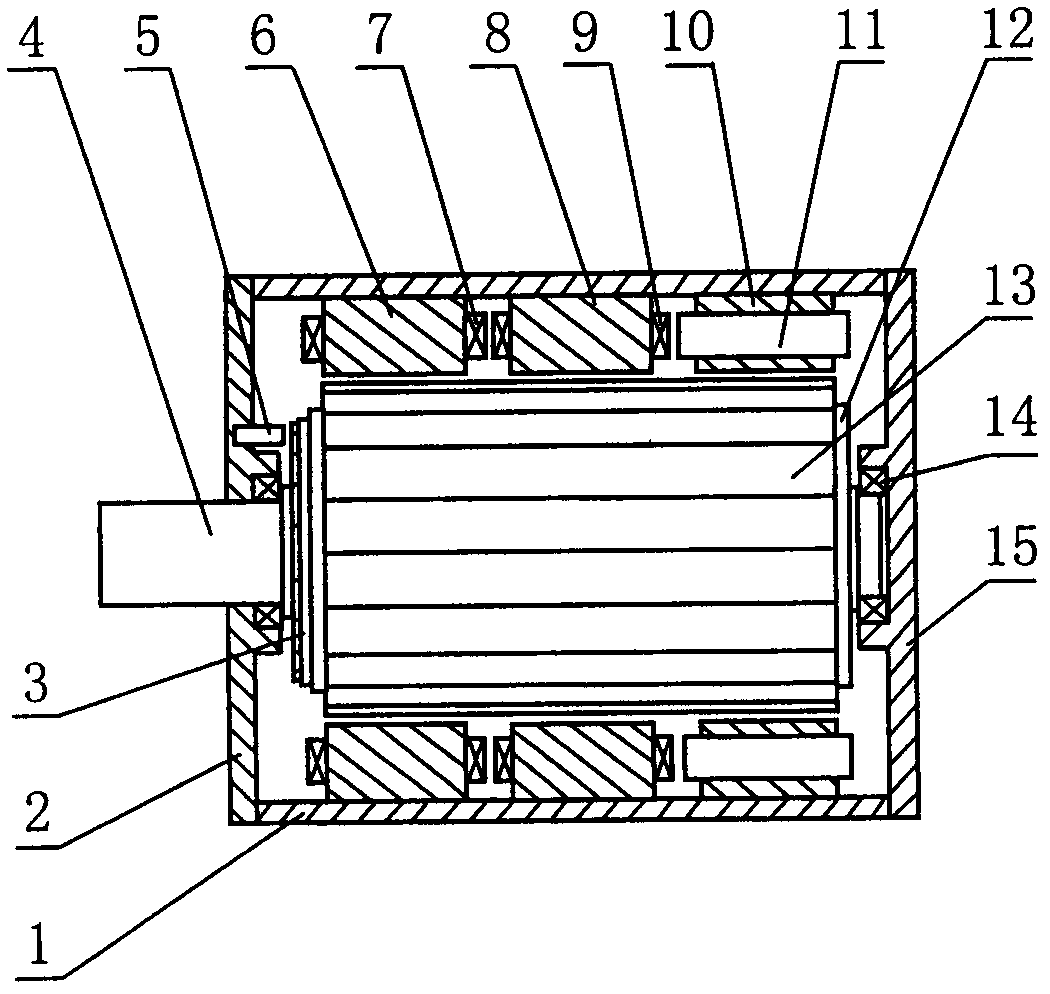

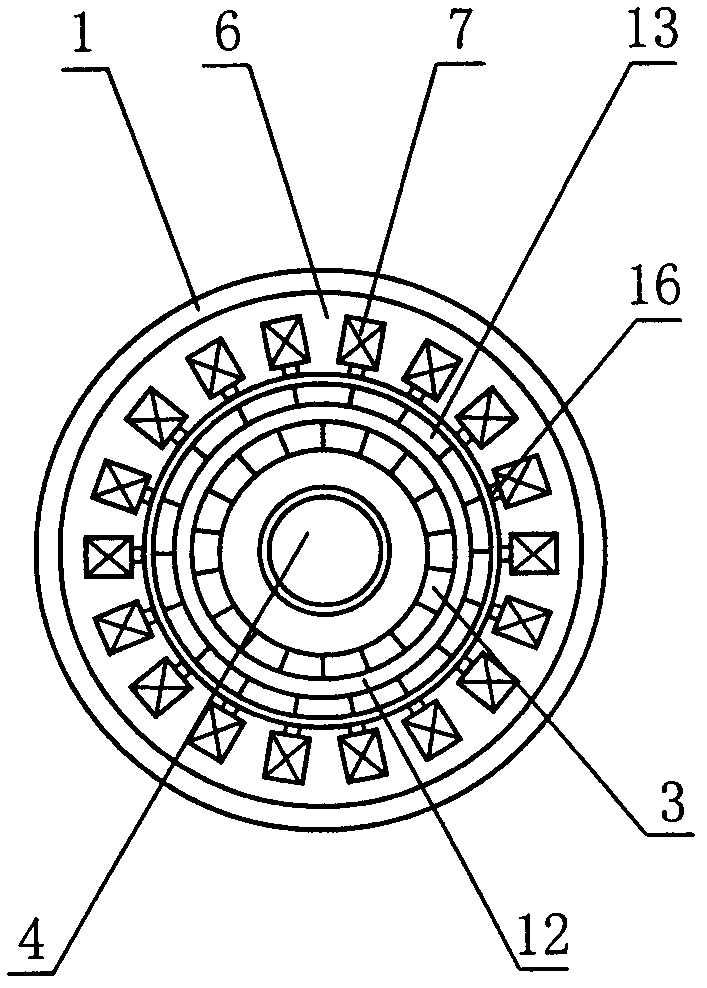

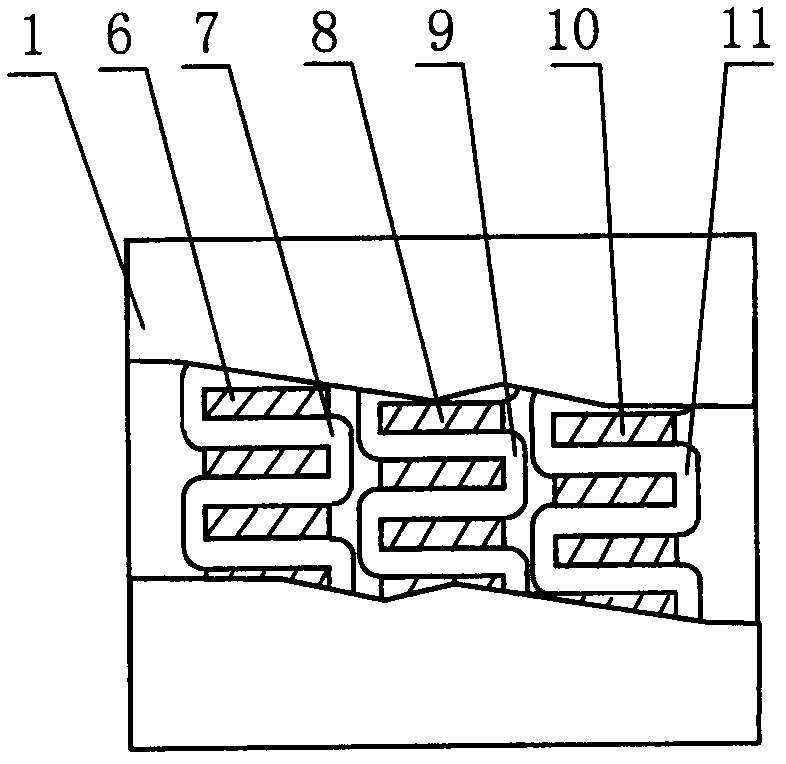

[0024] The present invention consists of a casing 1, a front end cover 2, a magnetic signal disk 3, a main shaft 4, a Hall sensor 5, a stator I6, a coil I7, a stator II8, a coil II9, a stator III10, a coil III11, a rotor 12, a rotor magnetic pole 13, a bearing 14 and the rear end cover 15, assembled in the following way: according to the width and depth of the stator slot, select flat wires of appropriate size, and stack several flat enameled wires with a certain width together according to the thickness to form a turn, several turns of flat enameled wire The thickness of the superimposed wire just meets the width of the stator wire slot, and then number each turn as A, B, C, D, E, F, etc., and mark it well. The thickness of each turn of flat wire should be less than 16 width, such as Figure 4As shown: firstly insert the first turn close to the magnetic pole core, and then insert the other several turns in turn. After the first wire slot is filled, then insert the second adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com