Tripolar effect permanent magnet direct current motor

A permanent magnet direct current, effect technology, applied in the direction of magnetic circuit, electric components, electrical components, etc., can solve the problem that the efficiency of permanent magnet motor cannot be doubled, and achieve high efficiency factor, improved energy saving effect, and stator tooth pole span small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

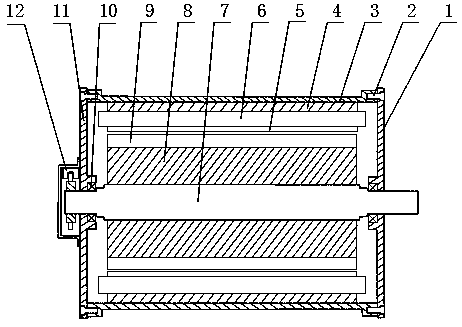

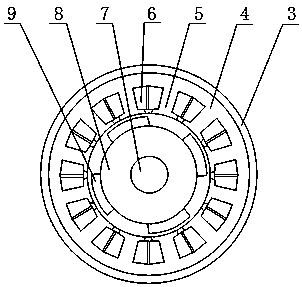

[0022] The stator 4 of the present invention is made by stacking silicon steel sheets, the rotor 8 is made of manganese steel or other non-magnetic materials, and the permanent magnet poles 9 are made of permanent magnet materials such as neodymium iron boron and ferrite, and are assembled in the following manner: The concentrated winding 6 is inserted into the wire slot of the stator tooth pole 5 in turn according to the three phases of A, B and C, and the wiring is drawn out, and the insulation treatment is carried out. The polarities of NS and SN are arranged alternately, the main shaft 7 is fixed to the rotor 8, the rear end of the main shaft 7 is used as an output shaft, and the stator 4 is fixed in the casing 3, supported by the front cover 1, the rear cover 11 and the bearing 10, The rotor 8 is suspended between the stators 4, and then the front cover 1, the rear cover 11 and the casing 3 are bolted by bolts 2, the detection disk 17 is fixed on the outside of the rear co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com