Regenerated automobile braking friction material and preparation method thereof

A technology of friction materials and automobile brakes, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of a large amount of grinding waste, and achieve no thermal degradation, good thermal conductivity, and wear resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1 Preparation method of regenerated automobile brake friction material

[0011] Recycling of waste materials, recycling of diamond material grinding tools to prepare grinding chips of friction materials, centralized recycling of production grinding chips, and removal of impurities through 20 mesh sieves, particle size control at less than 20 mesh, moisture content less than 2%, packed in 25 kg bags, sealed, and placed in a dry and ventilated warehouse; wrapped and granulated, the particle size is controlled within 30 mesh.

[0012] According to the weight ratio of grinding chips, nano-modified phenolic resin, nitrile rubber, basalt fiber, silicon carbide and boron nitride, it is 30~50:10~12:2~4:10~20:0.5~1:5~ 10 Ingredients, pressed and molded, vulcanized to obtain the friction plate;

[0013] The above-mentioned friction plate is welded and bonded with the brake pull arm, tendon and shoe plate to produce a regenerative environment-friendly automobile brake pla...

Embodiment 2

[0014] Example 2 Investigation of Braking Performance of Regenerated Automobile Braking Friction Material

[0015] The regenerative environment-friendly automobile brake friction material 3) described in Example 1 is welded and bonded with the brake pull arm, tendon and shoe to make a regenerative environment-friendly automobile brake pad.

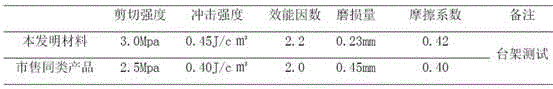

[0016] According to the JASO C 406 test, the second performance test, when 100Km / h, 0.6G, the braking performance factor is above 2.2, and the braking performance factor of ordinary products is 2.0.

[0017] According to the JASO C 406 test, the wear amount is less than 0.5mm, and the wear amount of ordinary products is less than 1.5mm.

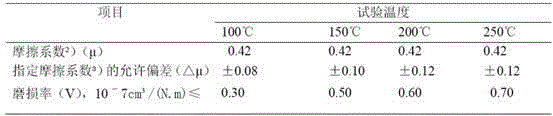

[0018] According to the national standard GB5763 test, the friction coefficient and wear rate are shown in Table 1 and 2.

[0019] Table 1 Investigation of the friction performance of recycled and environmentally friendly automobile brake friction materials

[0020]

[0021] Note: The test temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com