Manufacturing method for drawing protein

A manufacturing method and technology of drawing protein, which is applied in the direction of plant protein processing and texturization, can solve the problems of only being used as feed, waste, and inability to form fiber filaments, etc., so as to improve texturization and fibrosis, reduce Manufacturing cost, effect of expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

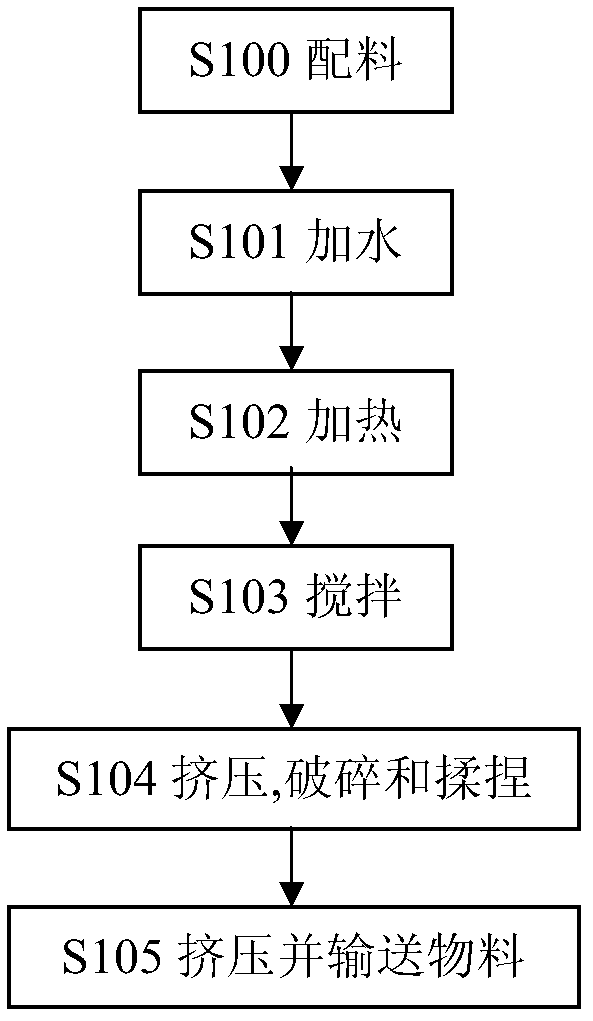

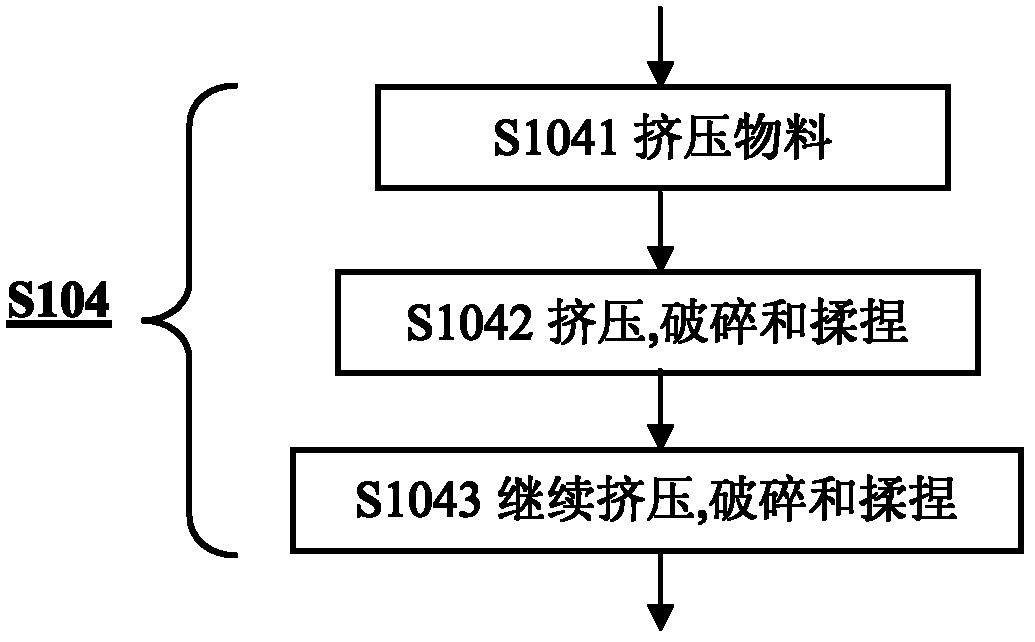

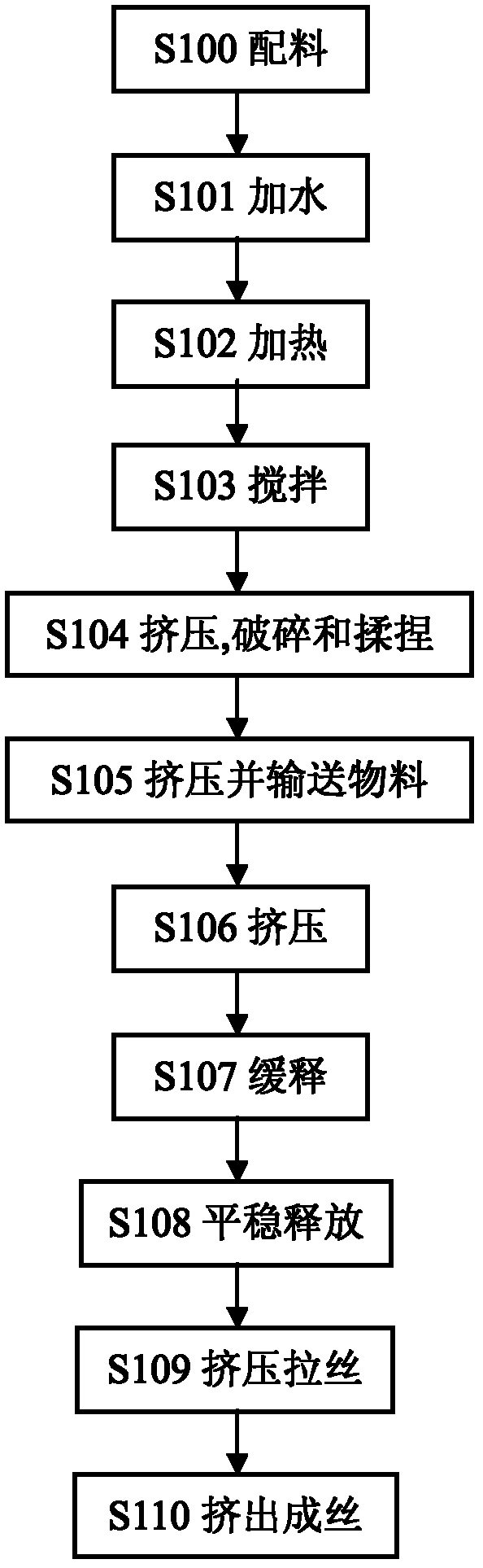

Method used

Image

Examples

example 1

[0096] Use about 85% high-temperature soybean meal and about 15% gluten powder to form the material, add about 20% of water relative to the total mass of the material, add high-temperature steam to raise the temperature of the material to about 95 degrees, and continue to add about 30% of water (relative to the total mass of the current material), the material is stirred by the rotation of the twin-screw at a temperature of about 100 degrees, and the material is conveyed forward by the screw at the same time. At a temperature of about 120 degrees, about 3-10kg / cm is provided by twin-screw rotation with a smaller pitch 2 Preliminary extrusion and stirring of the material by the high extrusion force to improve the viscosity of the material. At a temperature of about 140 degrees, the twin-screw rotation with smaller pitch and helical groove provides greater extrusion force to squeeze, crush and knead the material, thereby further improving the viscosity of the material. At a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com