Screw rod supporting device on planer type milling machine with moving workbench

A technology of gantry milling machine and support device, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., which can solve problems such as screw deflection deformation, reduce machine tool stability, and feed axis movement accuracy error, etc., to reduce positioning Accuracy error and its impact on workpiece processing accuracy, increase stability and safety, and eliminate bending and deflection deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

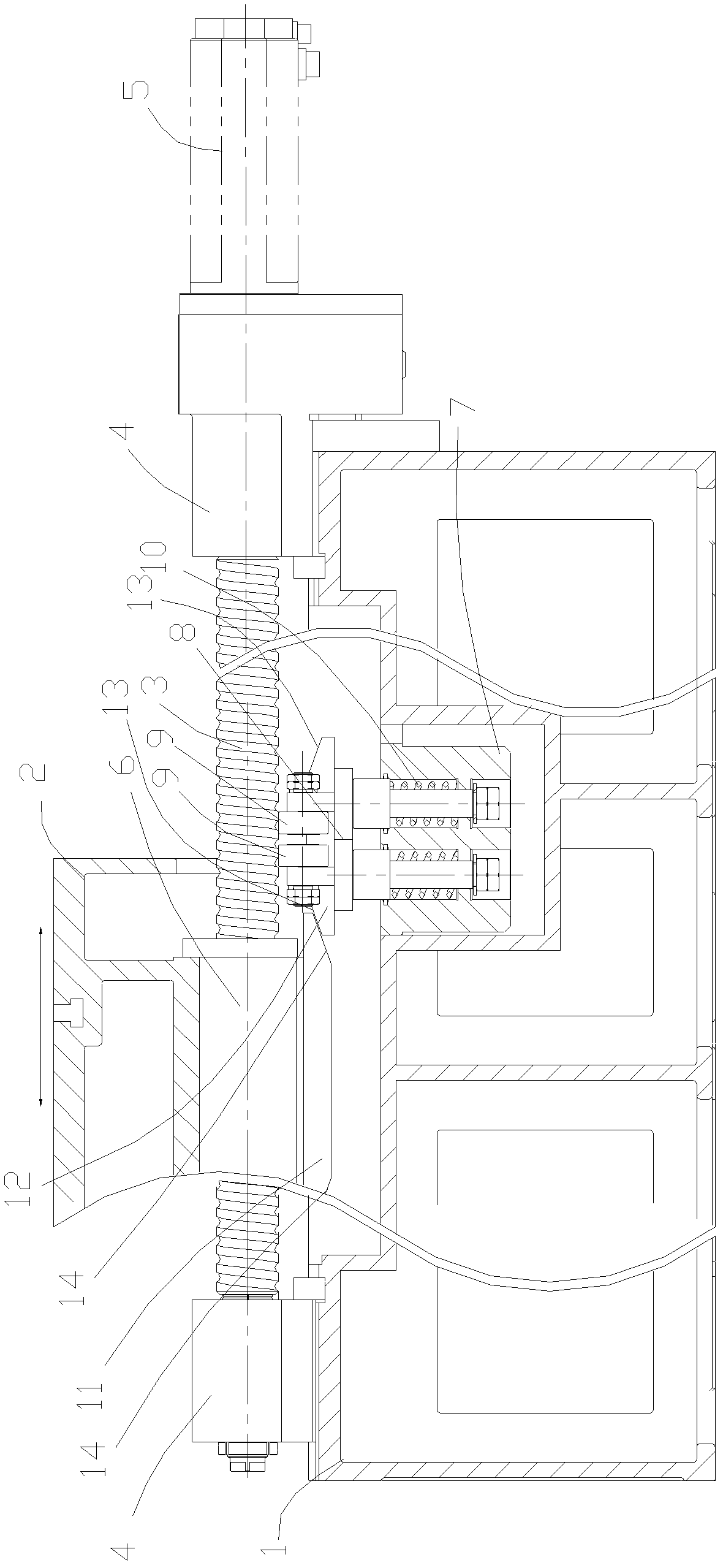

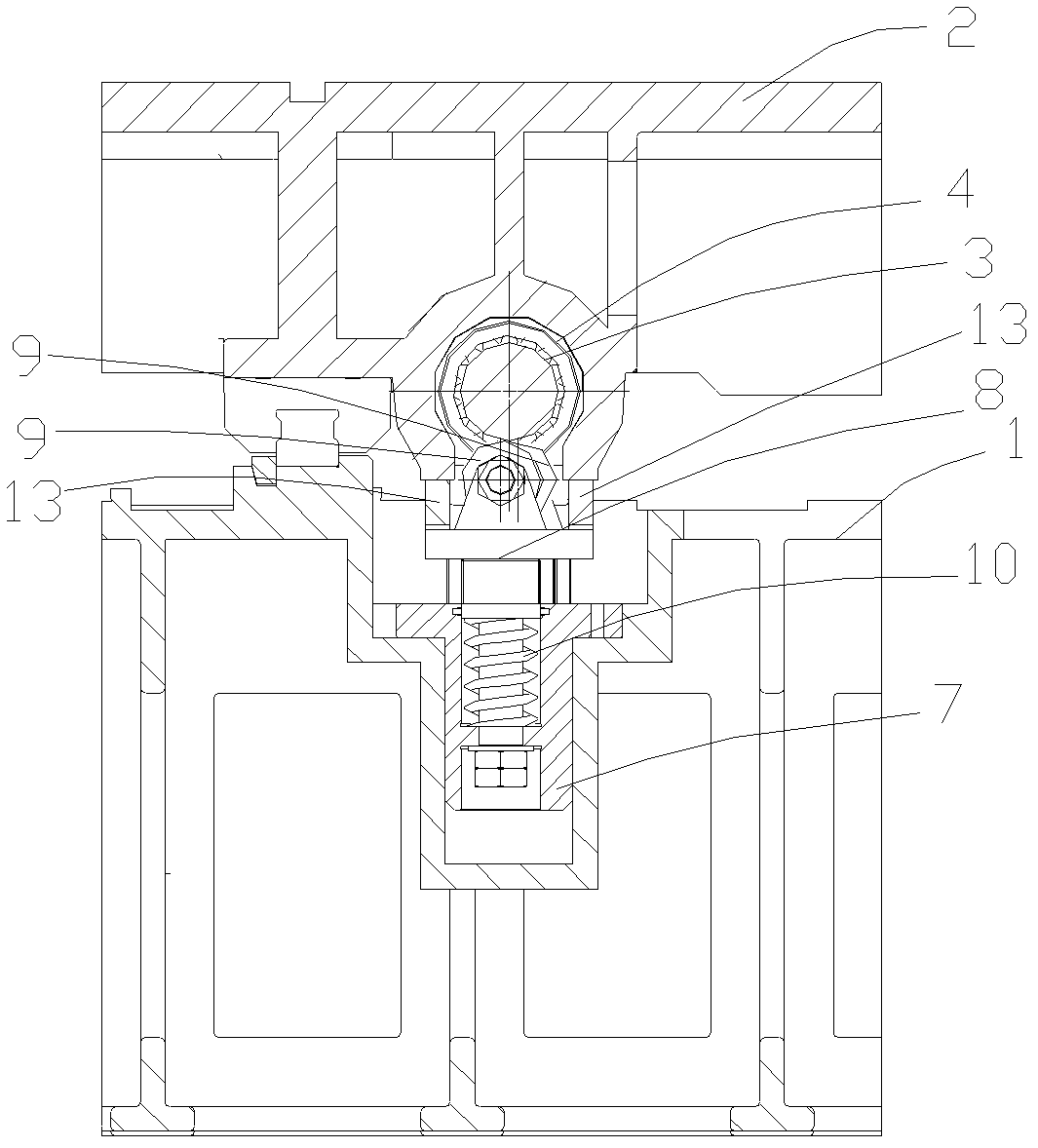

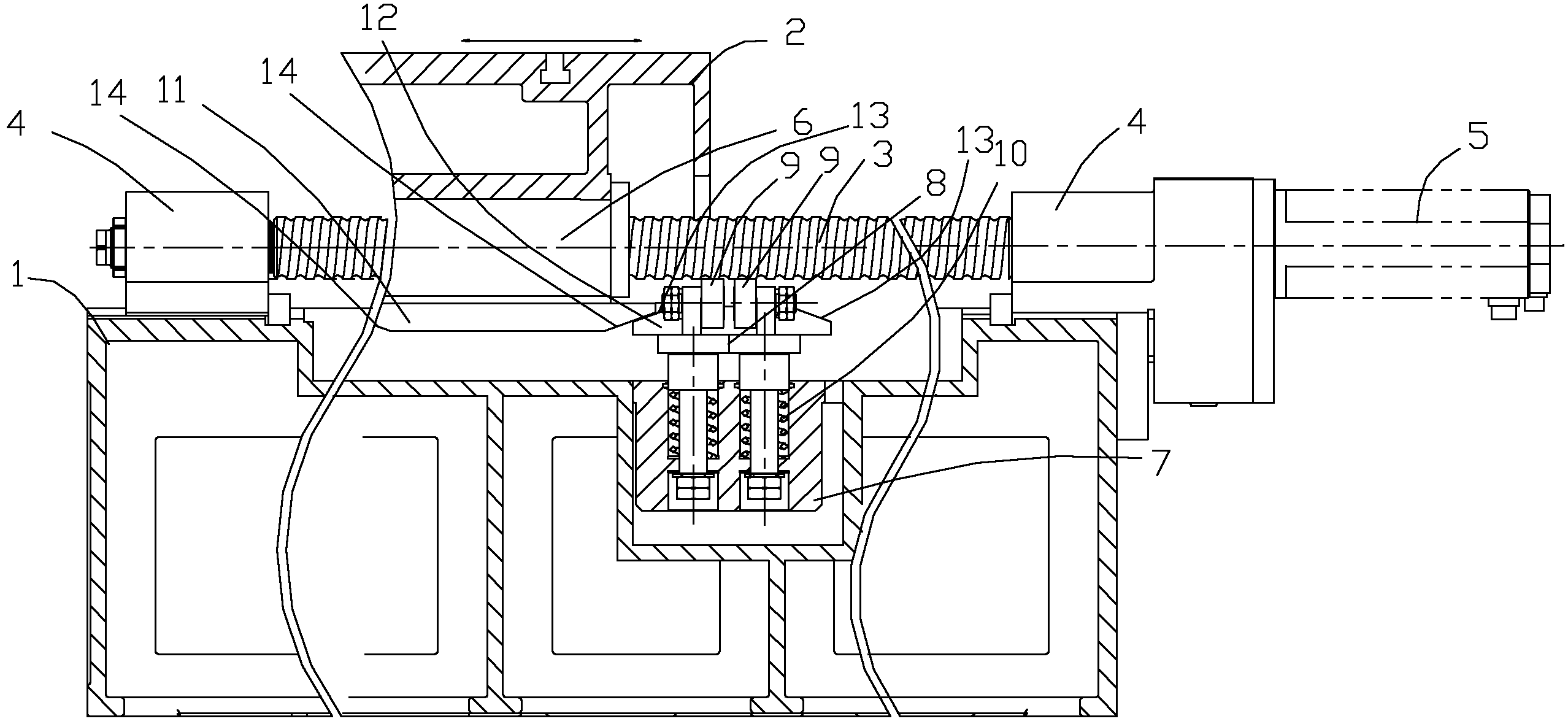

[0011] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] see Figure 1-2 As shown, on the workbench mobile gantry milling machine, the screw support device includes a bed 1, a workbench 2, a screw 3, a nut 6, a motor 5, a mounting seat 7, a support 8, a pair of rollers 9, an elastic member 10. Both ends of the lead screw 3 are provided with bearings, and the bearings at both ends of the lead screw 3 are set on the bed 1 through the bearing housing 4, the lead screw 3 can rotate, and the rotating lead screw 3 is driven by the motor 5, The thread on the lead screw 3 is matched with a nut 6, the nut 6 is fixed with the workbench 2, the lead screw 3 rotates, the nut 6 moves back and forth along the length direction of the lead screw 3, then the workbench 2 moves forward and backward, and the lead screw 3 moves back and forth. The length direction extends horizontally, such as figure 1 , a mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com