Wing full-motion airplane without rudder surface

A technology without rudder surfaces and wings, which is applied to aircraft parts, aircraft controls, aircraft transmissions, etc., can solve the problems of reduced aircraft performance, complex mechanism, and low cost performance, and achieve good stability and rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

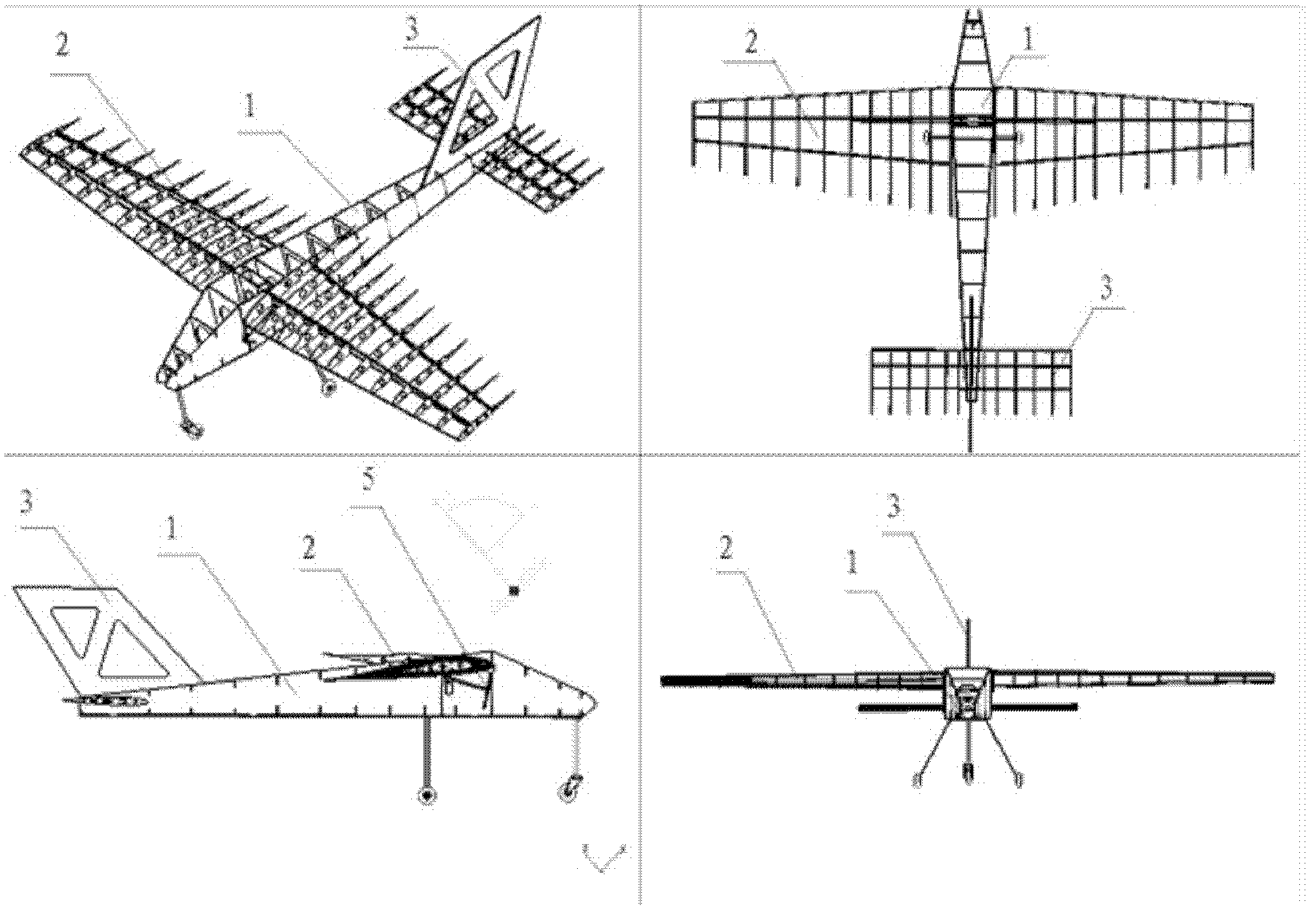

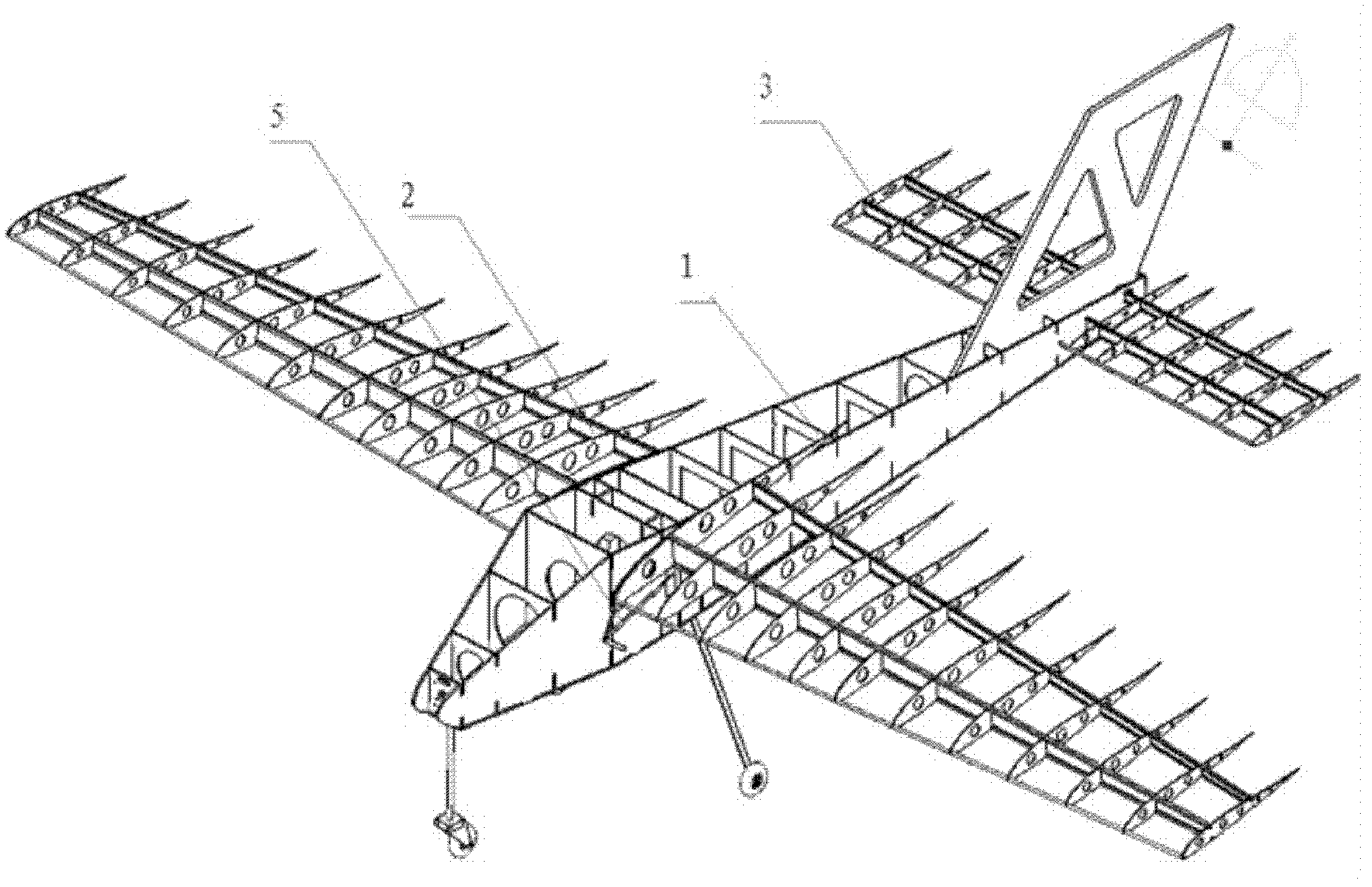

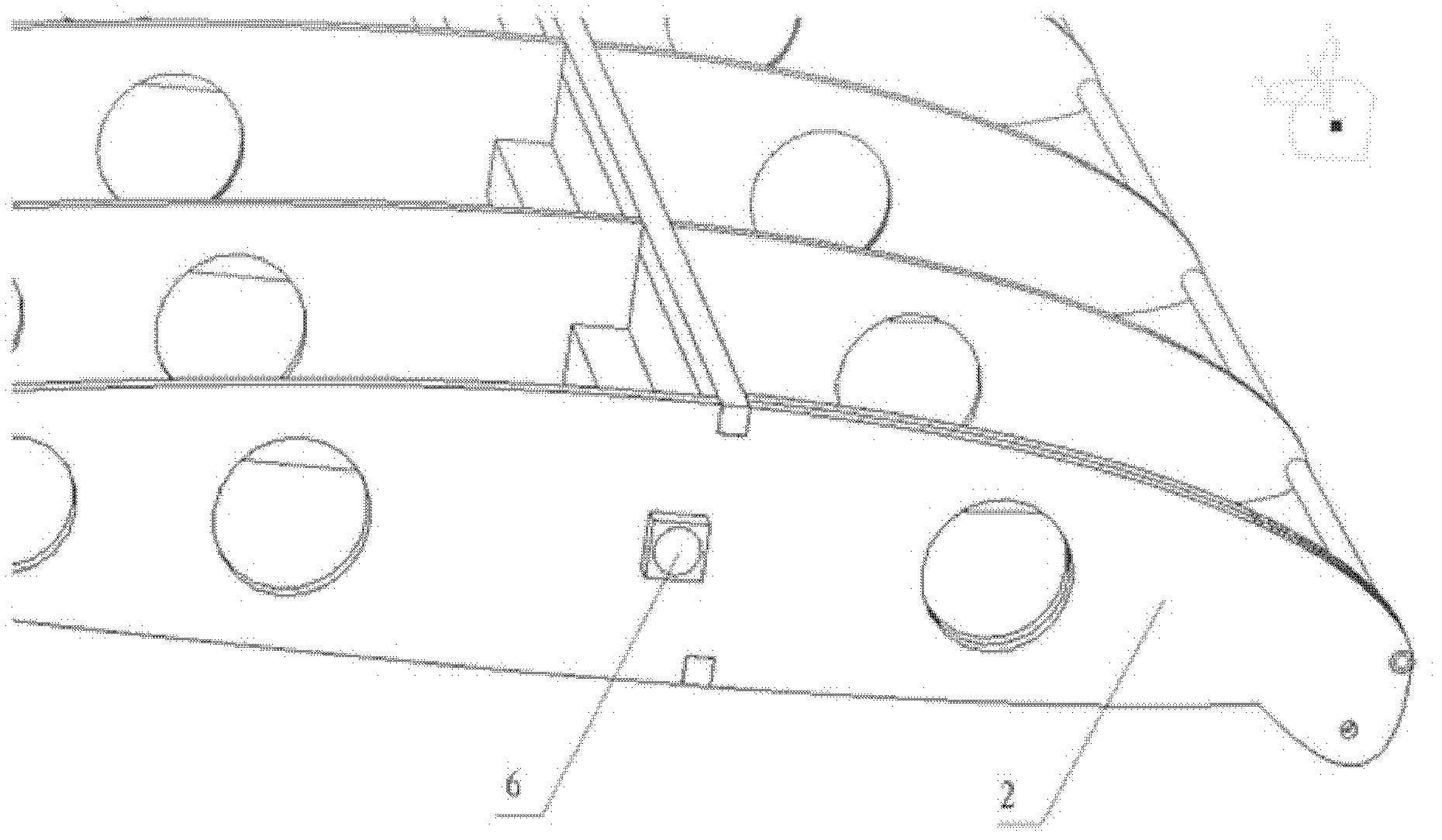

[0023] The non-rudder wing all-moving aircraft of the present embodiment is as Figure 1~8 As shown, it includes a wing, a power system and a fuselage. The wing is connected to the fuselage through a rotating shaft mechanism, and the power system is located in the fuselage, and a drive mechanism connected to the power system is provided on the fuselage. The driving mechanism is connected with the leading edge of the wing.

[0024] The main beam web of the wing is provided with a shaft sleeve, which is fixedly connected to the wing, and a circular shaft is fixed at the corresponding position of the wing main beam on the fuselage, and the shaft diameter forms a gap with the inner diameter of the sleeve. Cooperate.

[0025] The fuselage and empennage are integrated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com