Clamping device for rubber belt

A clamping device and tape technology, applied in the directions of transportation, packaging, conveyors, etc., can solve the problems of high labor intensity, small construction space, and intensive construction personnel, and achieve simple and convenient maintenance operations, shortened installation work time, The effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

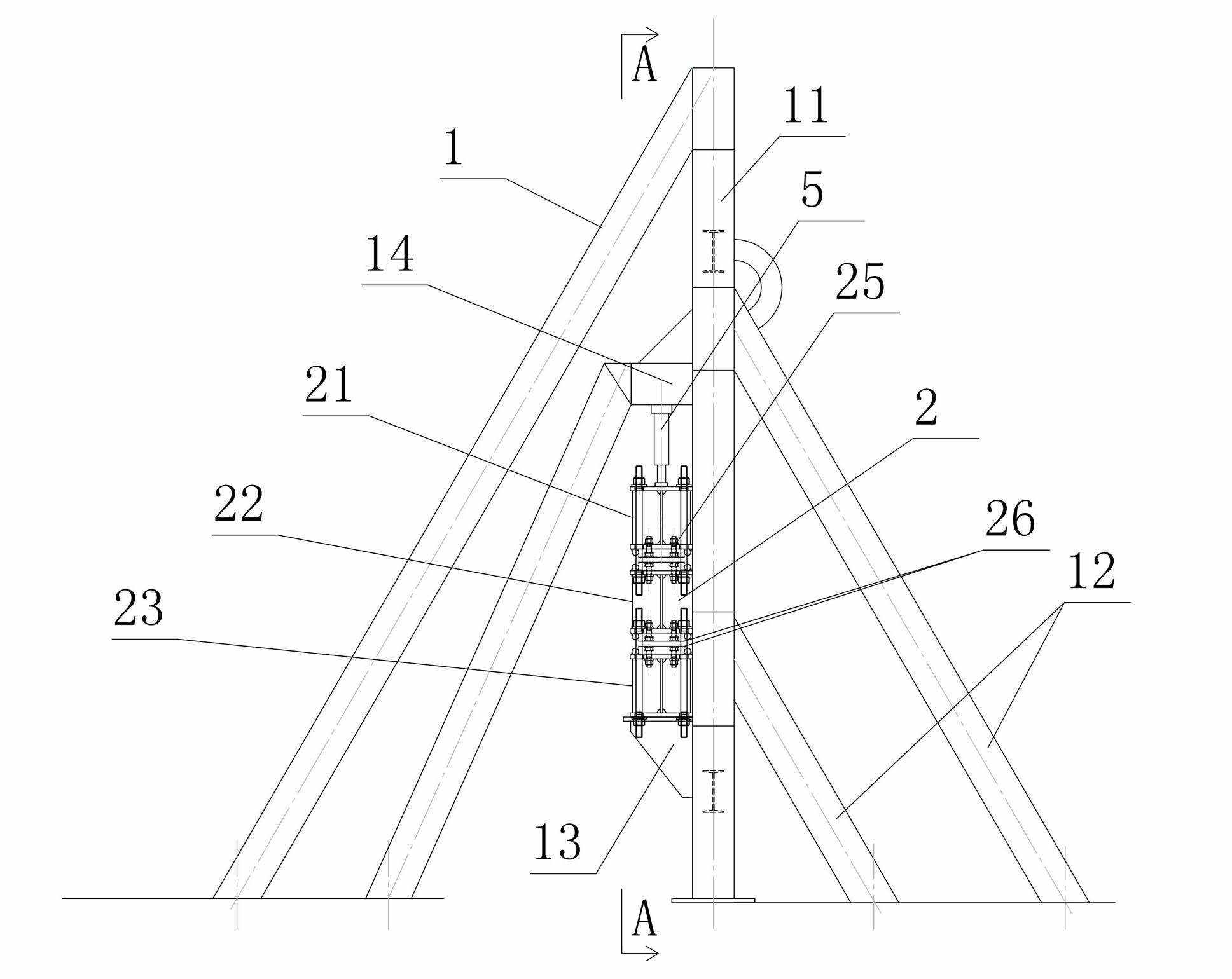

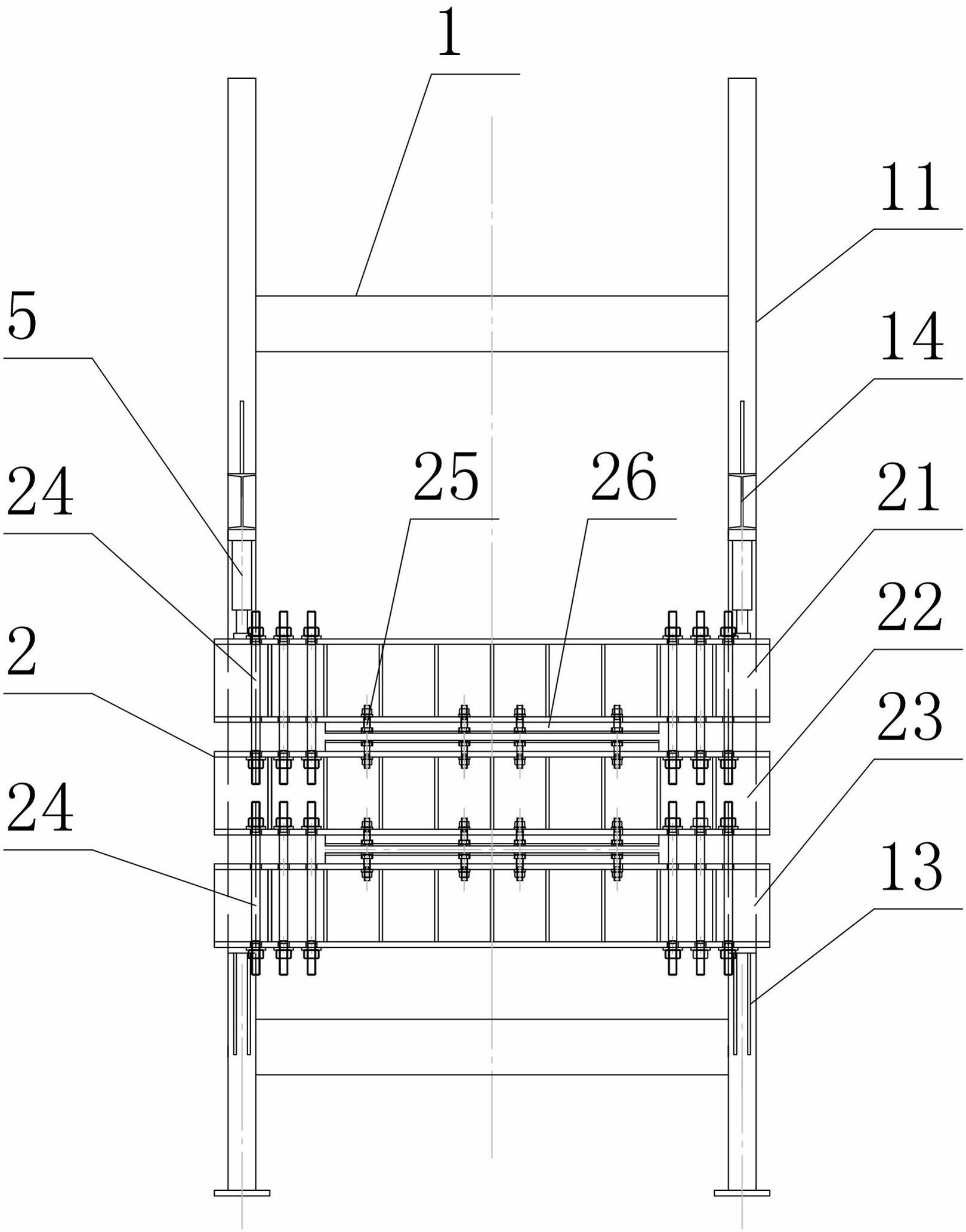

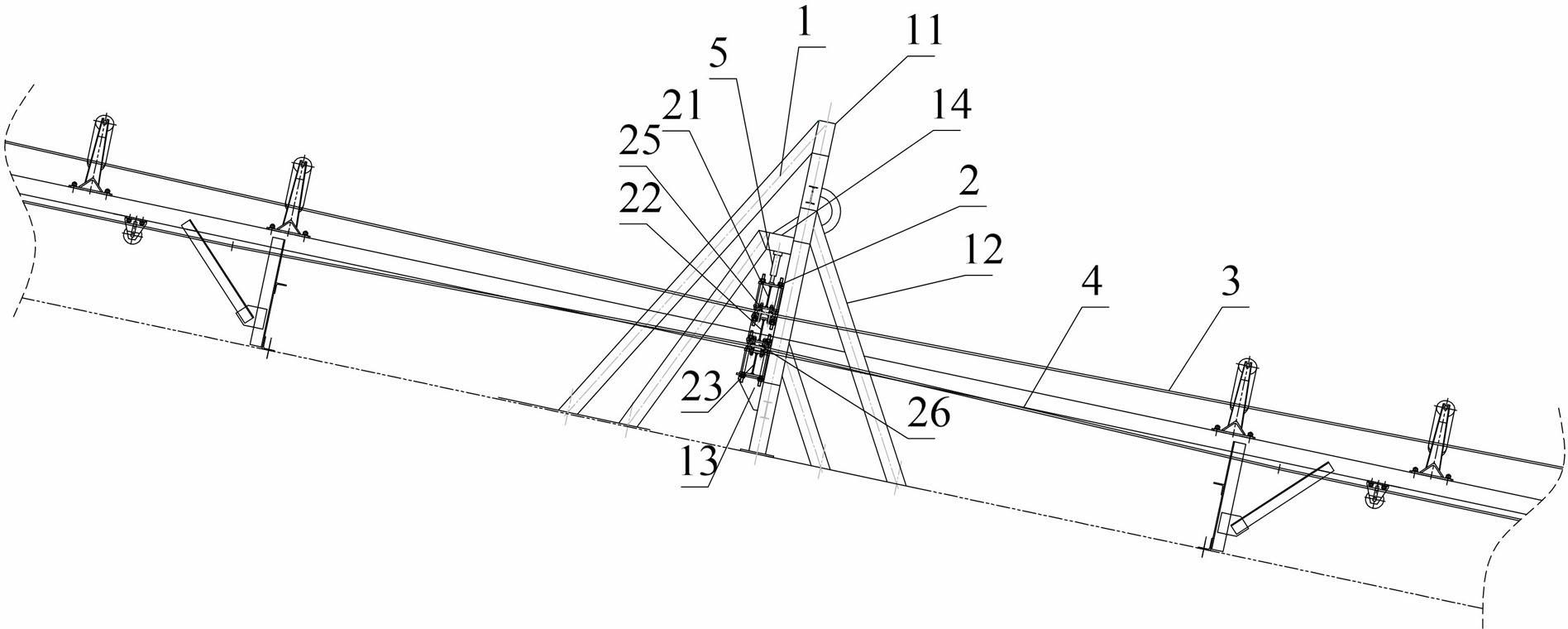

[0019] a kind of like Figure 1 ~ Figure 3 The tape clamping device of the present invention shown includes a fixed bracket 1, which is composed of a vertical support 11 in the middle and oblique supports 12 (slanted wedge irons) on both sides. A tape clamp 2 is installed on one side of the vertical support 11, and the tape clamp 2 is mainly composed of an H-shaped steel clamping beam (the horizontal length of the steel clamping beam is greater than the width of the vertical support 11 of the fixed bracket 1 ), including an upper clamping beam 21 , a middle clamping beam 22 and a lower clamping beam 23 . Between the upper clamping beam 21 and the middle clamping beam 22, the passage opening of the upward adhesive tape 3 is set, between the middle clamping beam 22 and the lower clamping beam 23, the passage opening of the downward adhesive tape 4 is set, and the upper clamping beam 21 and the middle clamping The tightening beams 22 are connected to each other through the faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com