Disassembling tool table for disassembling engine brake

A technology of brakes and tool tables, which is applied to lifting devices, lifting frames, etc., can solve problems such as no lifting point, piston jamming, and inability to use guide chains, etc., to improve safe and stable operation, facilitate disassembly and installation, and save energy. Effect of Overhaul Effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

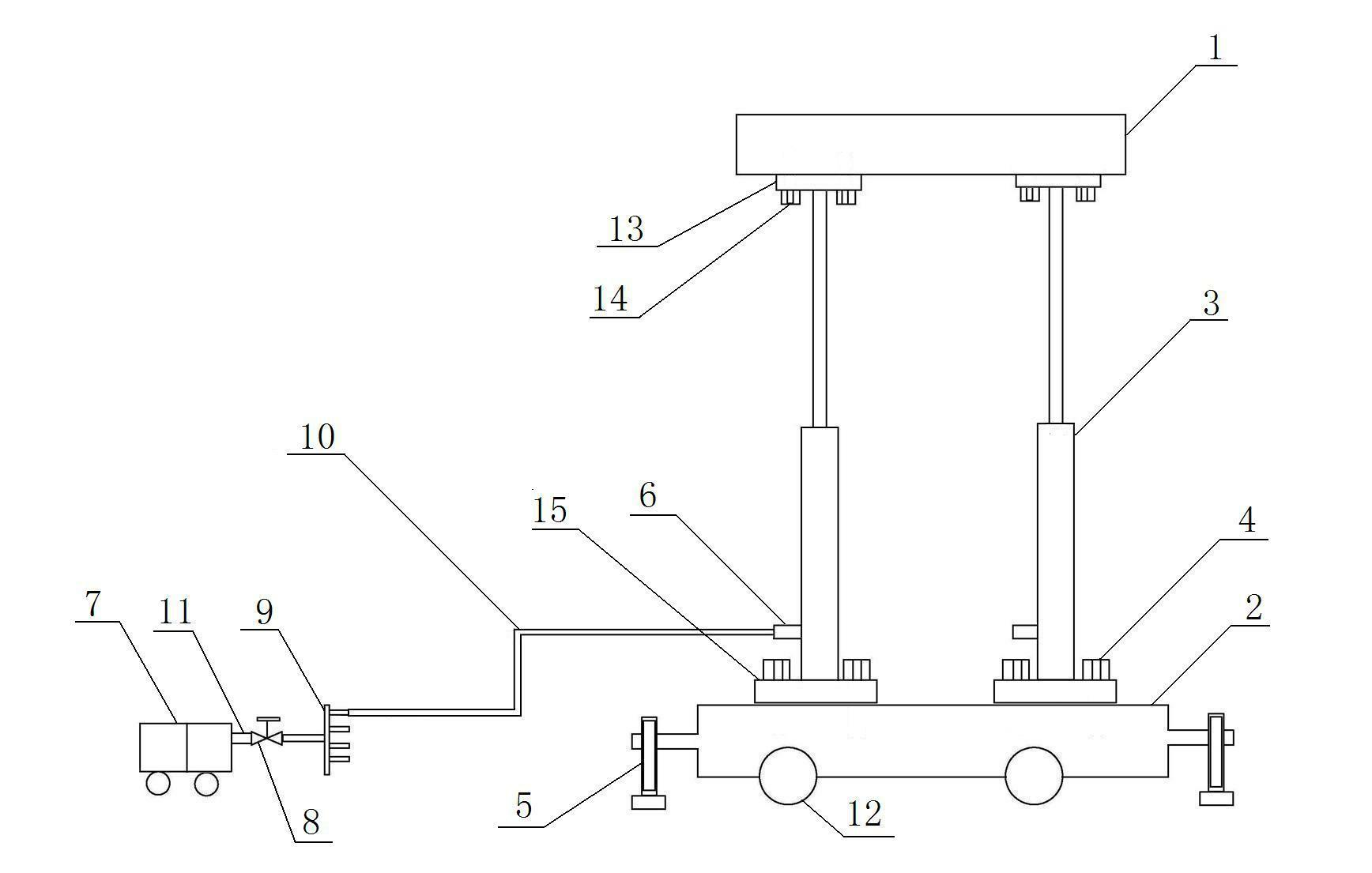

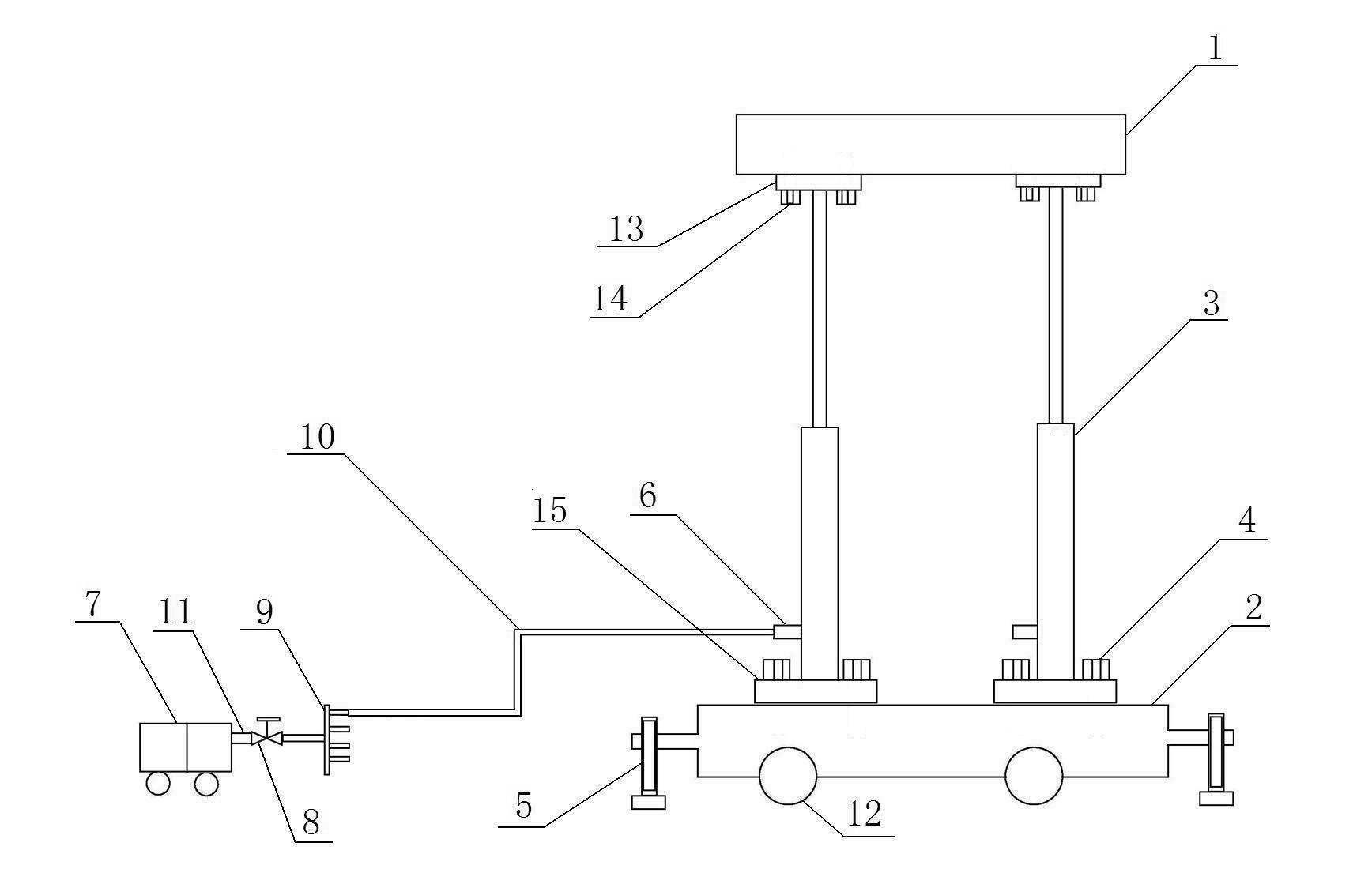

[0010] as attached figure 1 As shown, the present invention includes an upper fixed worktable 1, a lower fixed base 2, a jack 3, an electric pressure test pump 7, a flow divider 9 and a hydraulic pipeline 10; Four jacks 3 are evenly arranged on both sides of the room, the upper base 13 at the upper end of the jack 3 is fixedly connected with the upper fixed worktable 1 through the upper bolt 14, and the lower base 15 at the lower end of the jack 3 is fixed with the lower fixed base 2 through the lower bolt 4 connection, each jack 3 side lower end is provided with a quick connector 6, the lower end of the lower fixed base 2 is provided with a walking wheel 12, and the 4 corners of the lower fixed base 2 are provided with horizontal adjustment bolts 5, and the horizontal adjustment bolts 5 adjust the lower fixed base 2 The electric pressure test pump 7 communicates with the flow divider 9 through the pipeline 11, a throttle valve 8 is set on the pipeline 11, and four or more hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com