Composite for optical material, and optical material

A technology of optical materials and compositions, applied in optics, optical components, instruments, etc., can solve problems such as loss, yellowness, and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

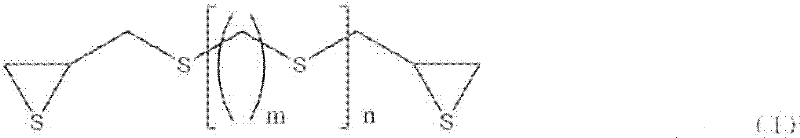

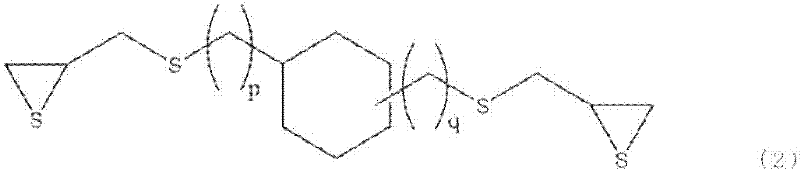

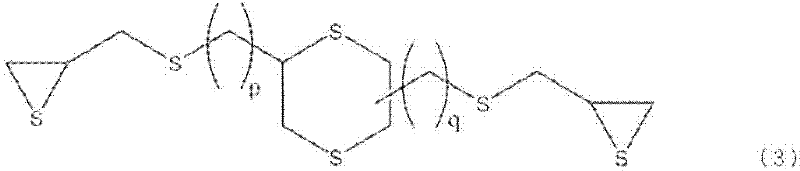

Image

Examples

Embodiment 1~3

[0079] Using bis(β-epithiopropyl) sulfide with the total content of iron, chromium and nickel shown in Table 1, adopt the method of polymerization method A to make a flat plate with a thickness of 5mm, and compare it with the blank sample to obtain △ Yi. The results are summarized in Table 1.

Embodiment 4~6

[0081] Using the bis(β-epithiopropyl) sulfide with the total content of iron, chromium and nickel shown in Table 1, adopt the method of polymerization method B to make a flat plate with a thickness of 5mm, and compare it with the blank sample to obtain △ Yi. The results are summarized in Table 1.

Embodiment 7~9

[0083] Using bis(β-epithiopropyl) sulfide with the total content of iron, chromium and nickel shown in Table 1, adopt the method of polymerization method C to make a flat plate with a thickness of 5mm, and compare it with the blank sample to obtain △ Yi. The results are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com