Double-drum hemp decorticator

A hemp stripping machine and double drum technology, applied in mechanical treatment, fiber mechanical separation, textile and papermaking, etc., can solve the problems of unclean removal of hemp green bark stems, low safety factor, low efficiency, etc., and achieve smooth rotation. Unobstructed, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples. The scope of application of the present invention is not limited to this example.

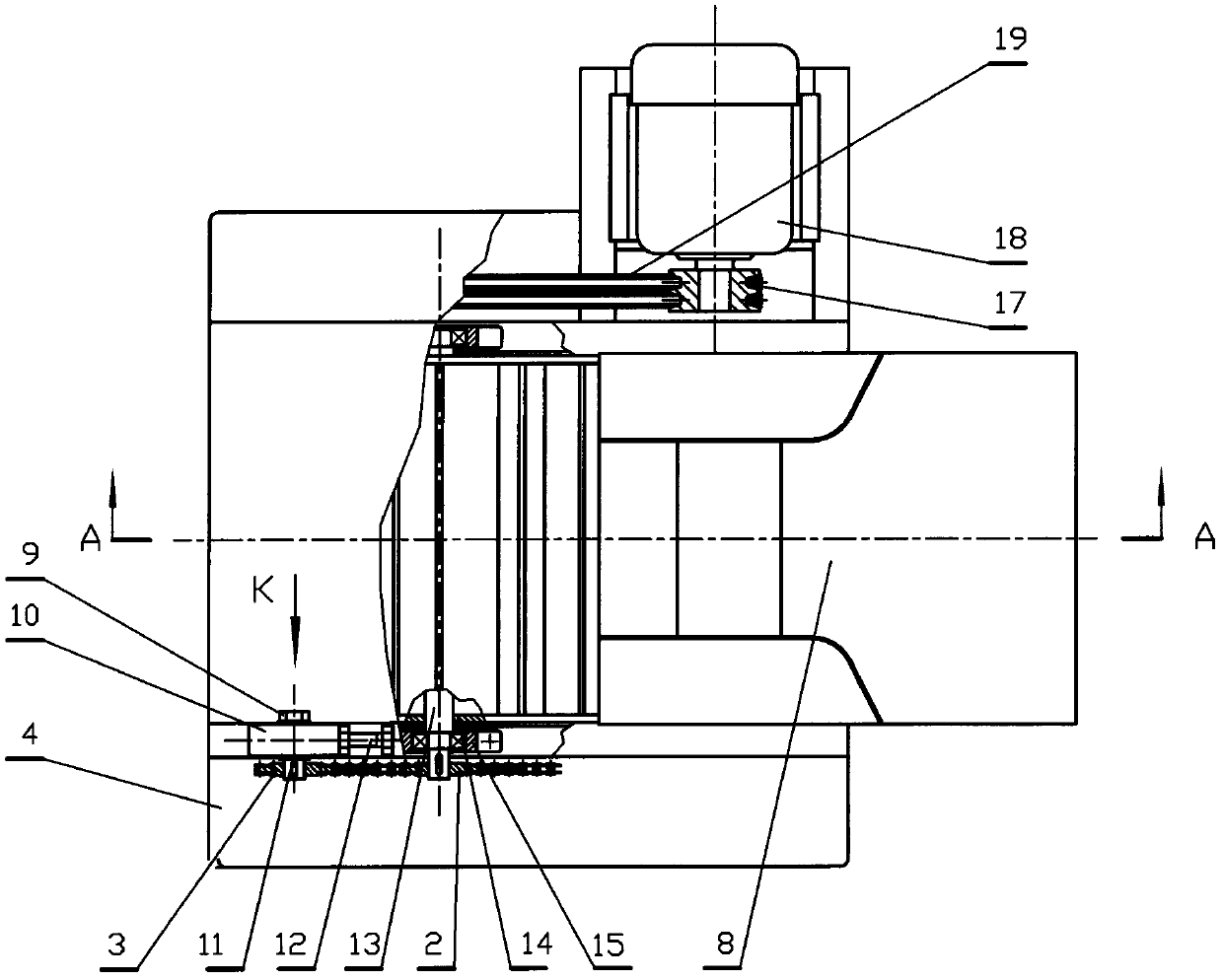

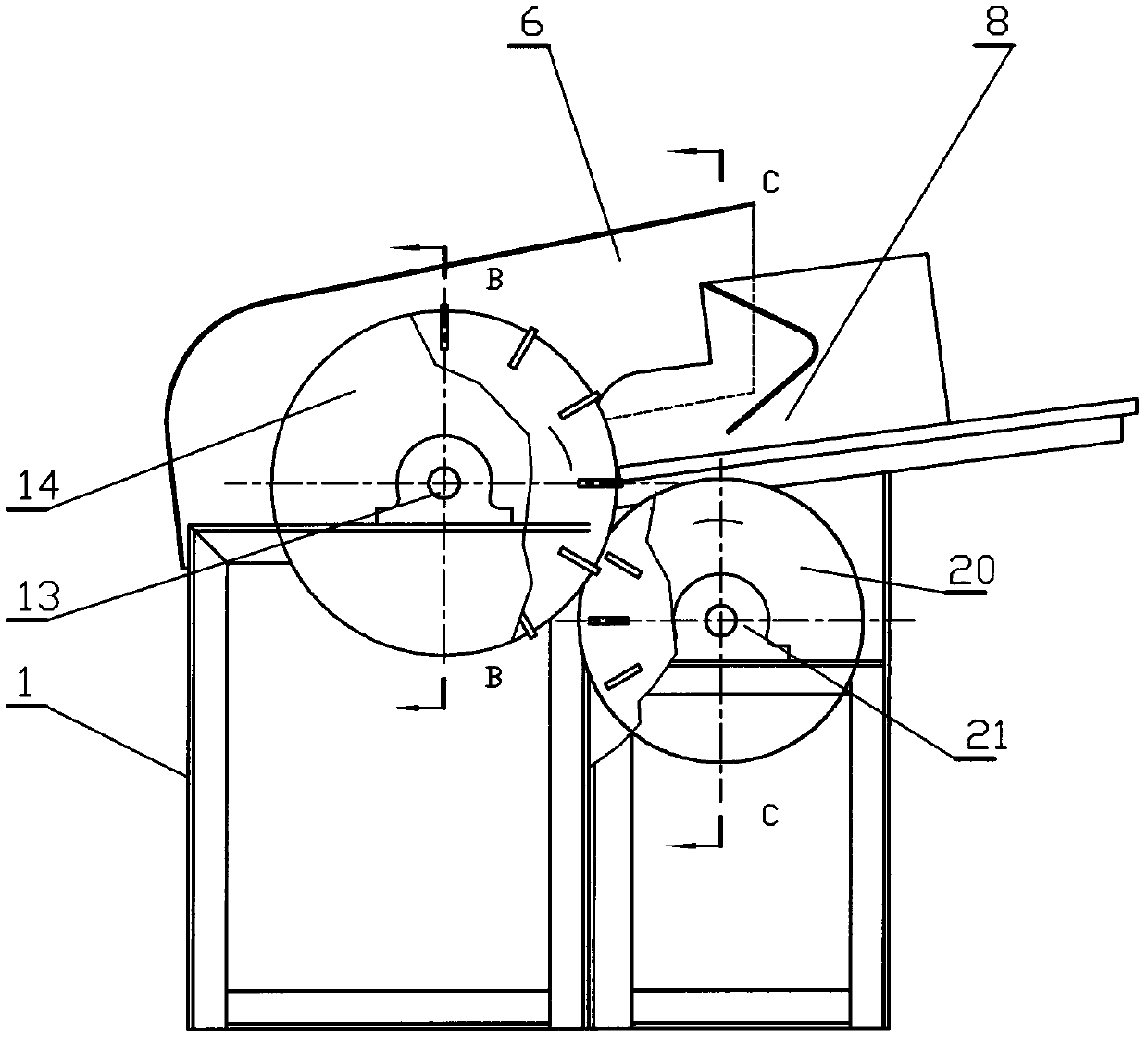

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , a double-drum stripping hemp machine, comprising a machine cover 6 with a feed port 8 mounted on the frame 1, an active stripping hemp wheel 14 and a passive stripping hemp wheel 20 are housed in the machine cover 6;

[0029] Wherein, between the machine cover 6 and the active stripping hemp wheel 14, the first desensitizing cavity is formed, the feed port 8 communicates with the first desensitization cavity, and the second desensitization cavity is formed between the machine cover 6 and the passive desensitization wheel 20. Cavity;

[0030] Drive the power mechanism 18 (motor) that actively strips the numbness wheel 14, is arranged on the transmission mechanism between the active numbness stripping whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com