Modularized quickly-assembled house

A housing and rapid technology, applied in the field of rapid housing assembly, can solve the problems of long installation process, many components, and complexity, and achieve the effects of good energy saving and environmental protection performance, convenient and simple transportation, and low transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

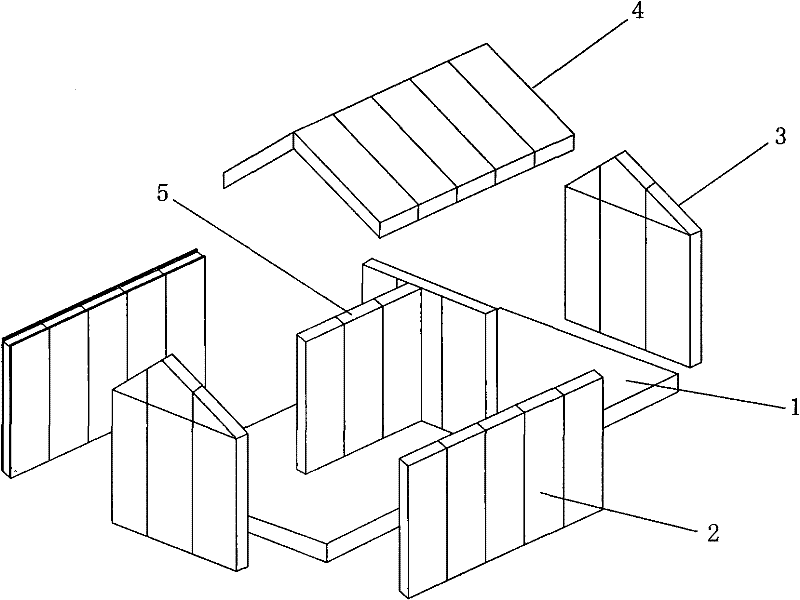

[0031] like Figure 1 to Figure 7 Shown, the present invention is a kind of fast assembly house, and this house comprises the following parts:

[0032] Floor 1, including the raised ground layer and the cast-in-place ground layer, the structure of the raised ground layer from top to bottom is the ground decoration layer (tile, wood floor), 18mm OSB (Matsumoto board), pasted XPS extruded foam board, and steel structure layer; The structure of the cast-in-place ground layer from top to bottom is the ground decoration layer (tiles, wooden floors), cast-in-place reinforced concrete structure layer, 200mm to 300mm EPS12KG / M3 foam board, PVC waterproof membrane, ground beams, and foundation.

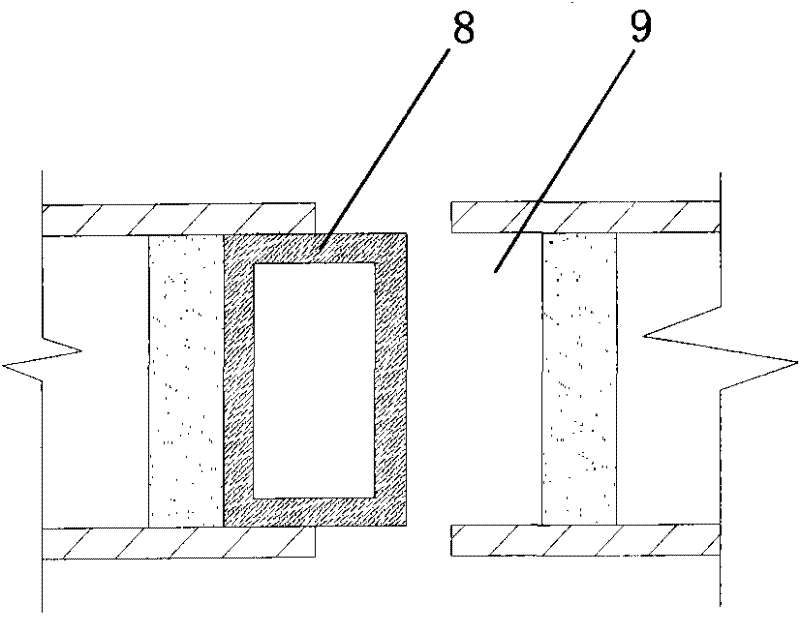

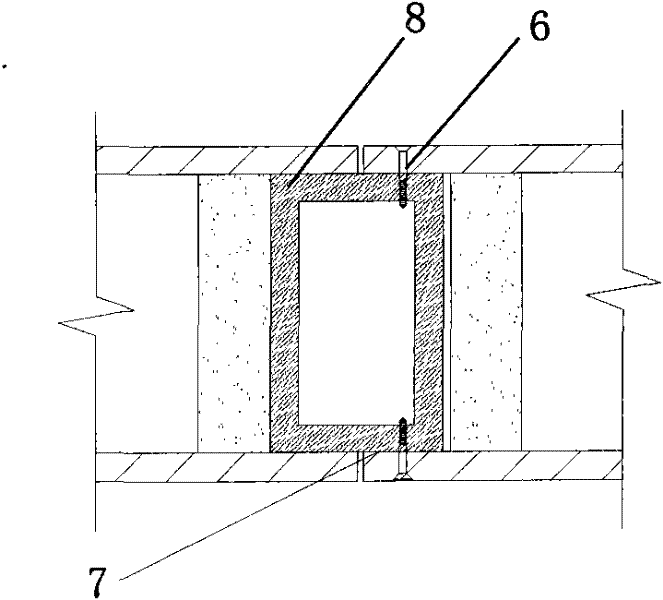

[0033] External wall, its structure from outside to inside is 15mm to 25mm outer decorative board layer, 20mm galvanized keel breathable layer, 9mm glass fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com