Wheel-type fan driving method and wheel-type fan

A driving method and fan technology, applied in non-variable-capacity pumps, machines/engines, pump devices, etc., can solve the problems of single appearance, influence, outdated technology, etc., and achieve the effect of high energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A method for driving a wheeled fan,

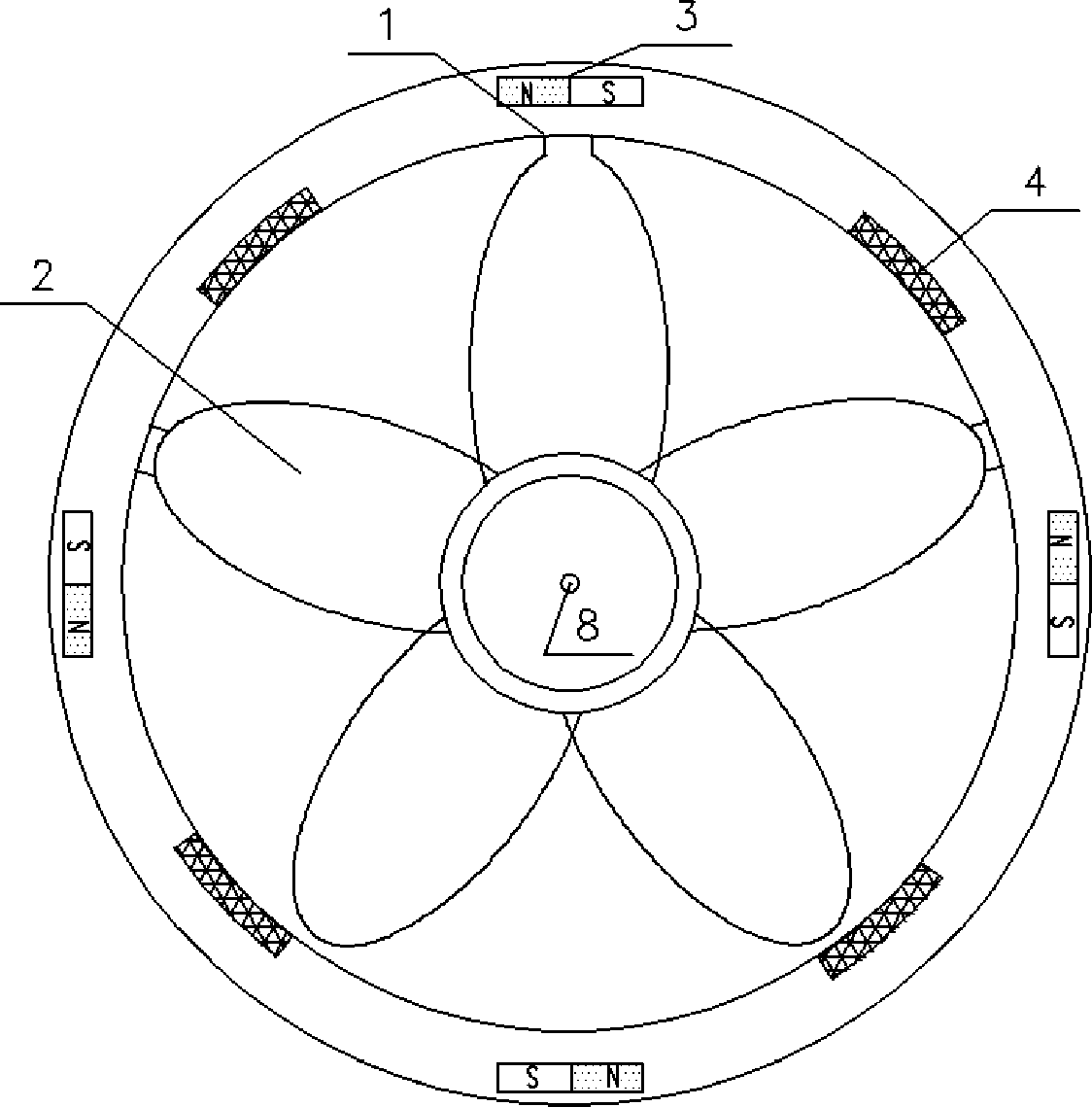

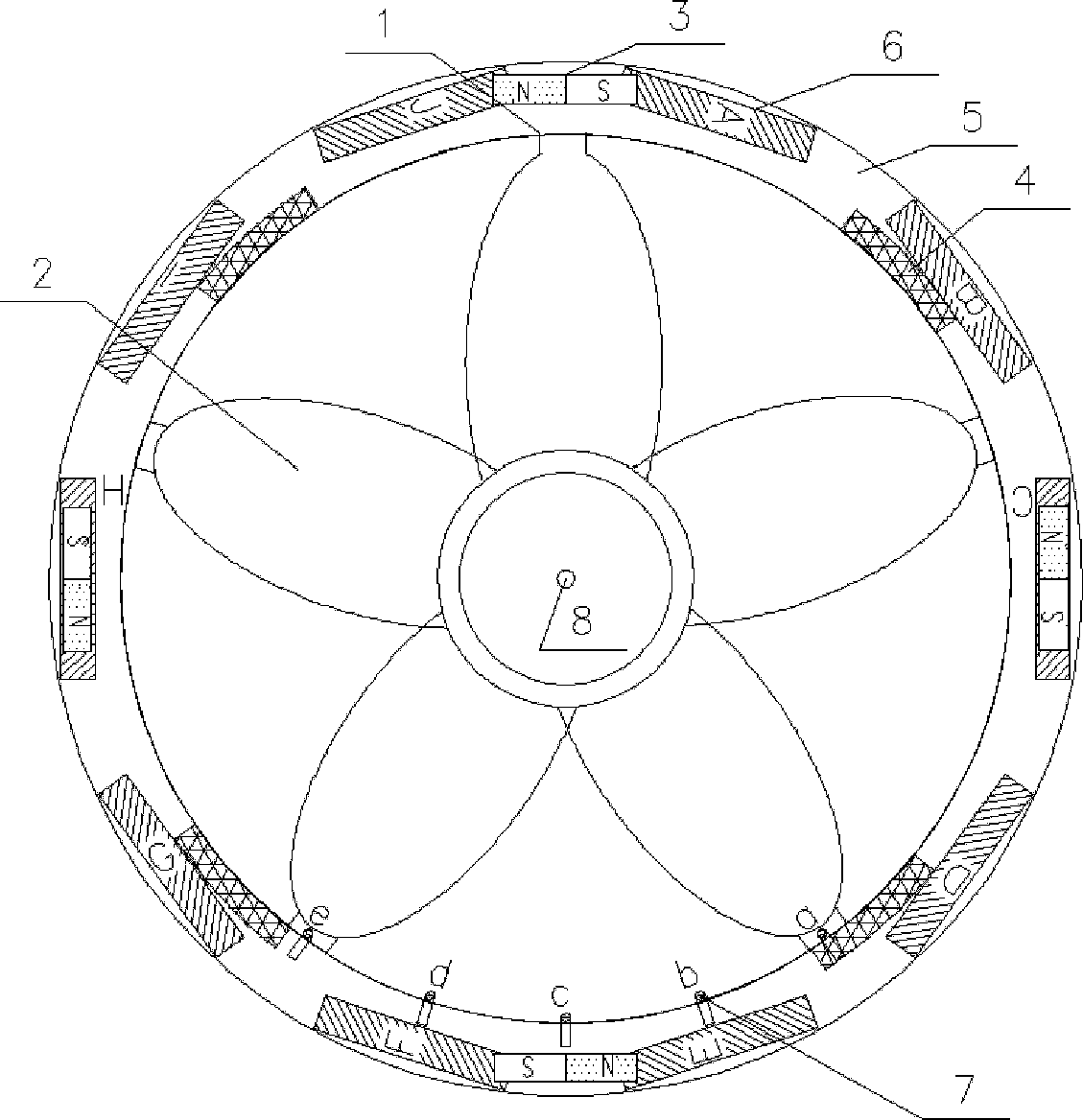

[0066] Step 1 Take a ring 1, connect the impeller 2 composed of blades to the ring 1, embed 4~8 permanent magnet blocks 3 on the ring 1 and distribute 4~8 permanent magnet blocks 3 along the circumferential direction, Set the reflective area 4 on the ring 1;

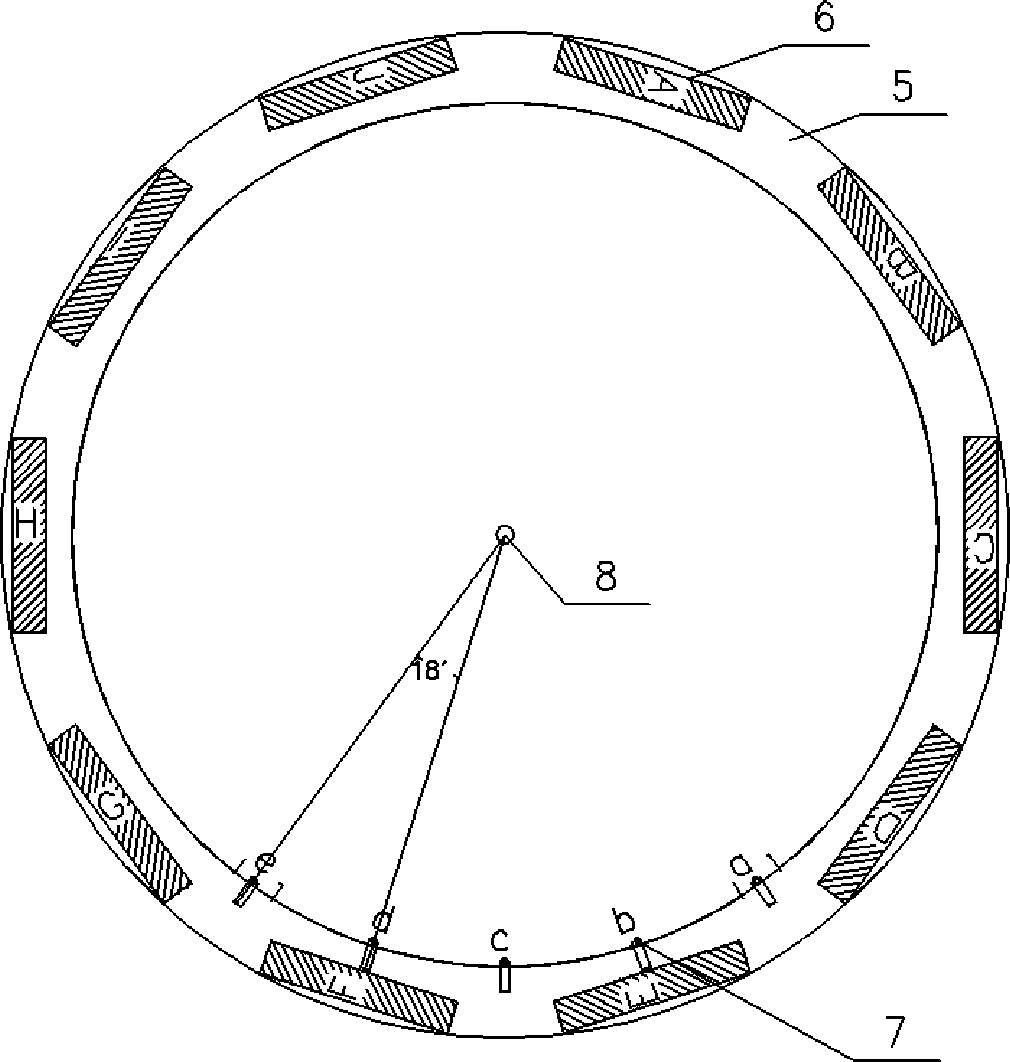

[0067] Step 2 Take a board and use the said board as the machine base 5, set 3~10 groups of electromagnetic coil groups 6 arranged along the circumference on the machine base 5 and photoelectric switches 7 whose number is the number of electromagnetic coil groups. The switch 7 respectively forms a series circuit with each group of electromagnetic coil groups;

[0068] Step 3: Set a rotating shaft 8, through which the circular ring 1 and the base 5 form a rotational connection, and make the surface of the circular ring 1 with the permanent magnet block 3 and the base 5 with the electromagnetic coil and the photoelectric switch 7 faces face to face;

[0069] Step 4 Power on e...

Embodiment 2

[0074] A wheeled fan, comprising a ring 1, an impeller 2, a machine base 5 and a rotating shaft 8, the impeller 2 is arranged in the ring 1, and 4 to 8 permanent magnet blocks 3 are embedded on the ring 1 and 4~ Eight permanent magnet blocks 3 are distributed along the circumferential direction, and a reflective area 4 is set on the ring 1; 3 to 10 sets of electromagnetic coils 6 arranged along the circumference and a number equal to the number of sets of electromagnetic coils are set on the base 5. Photoelectric switch 7, each photoelectric switch 7 is connected in series with each pair of electromagnetic coil groups respectively to form a series loop; Described impeller 2 forms rotational connection with support 5 by rotating shaft 8, is provided with the surface of the circular ring 1 of permanent magnet block 3 and sets The surfaces of the base 5 with the electromagnetic coil and the photoelectric switch 7 face each other; when each series circuit is powered on and the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com