Octagonal closed-type bearing bracket connected with shell

A bearing bracket and octagonal technology, which is applied in the field of octagonal closed bearing brackets, can solve problems such as increasing mold manufacturing costs and equipment management costs, personal safety and environmental pollution risks, and extending the axial dimension of bearing frames. Achieve the effect of saving mold costs and equipment management costs, avoiding personal safety hazards, and reducing the number of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

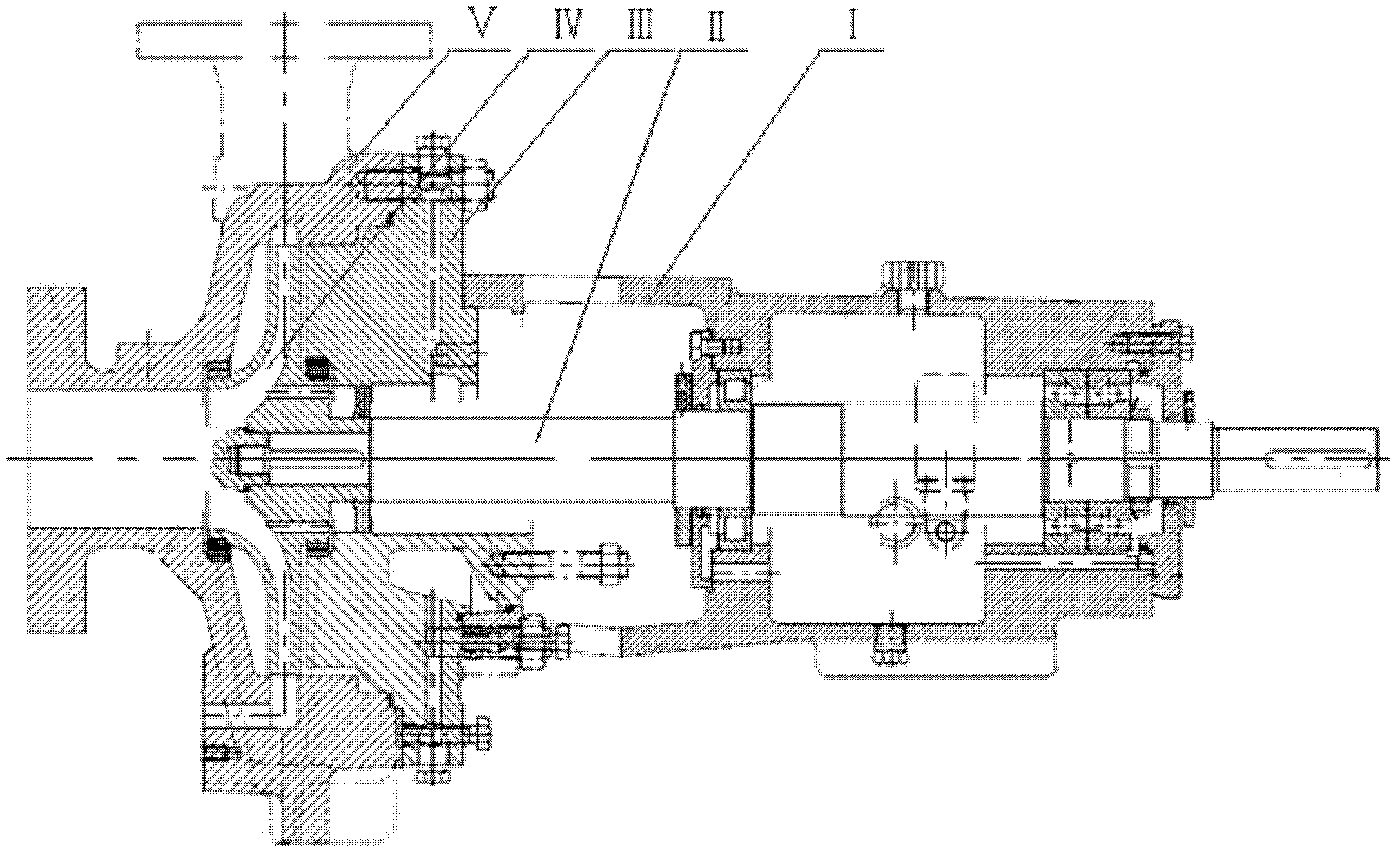

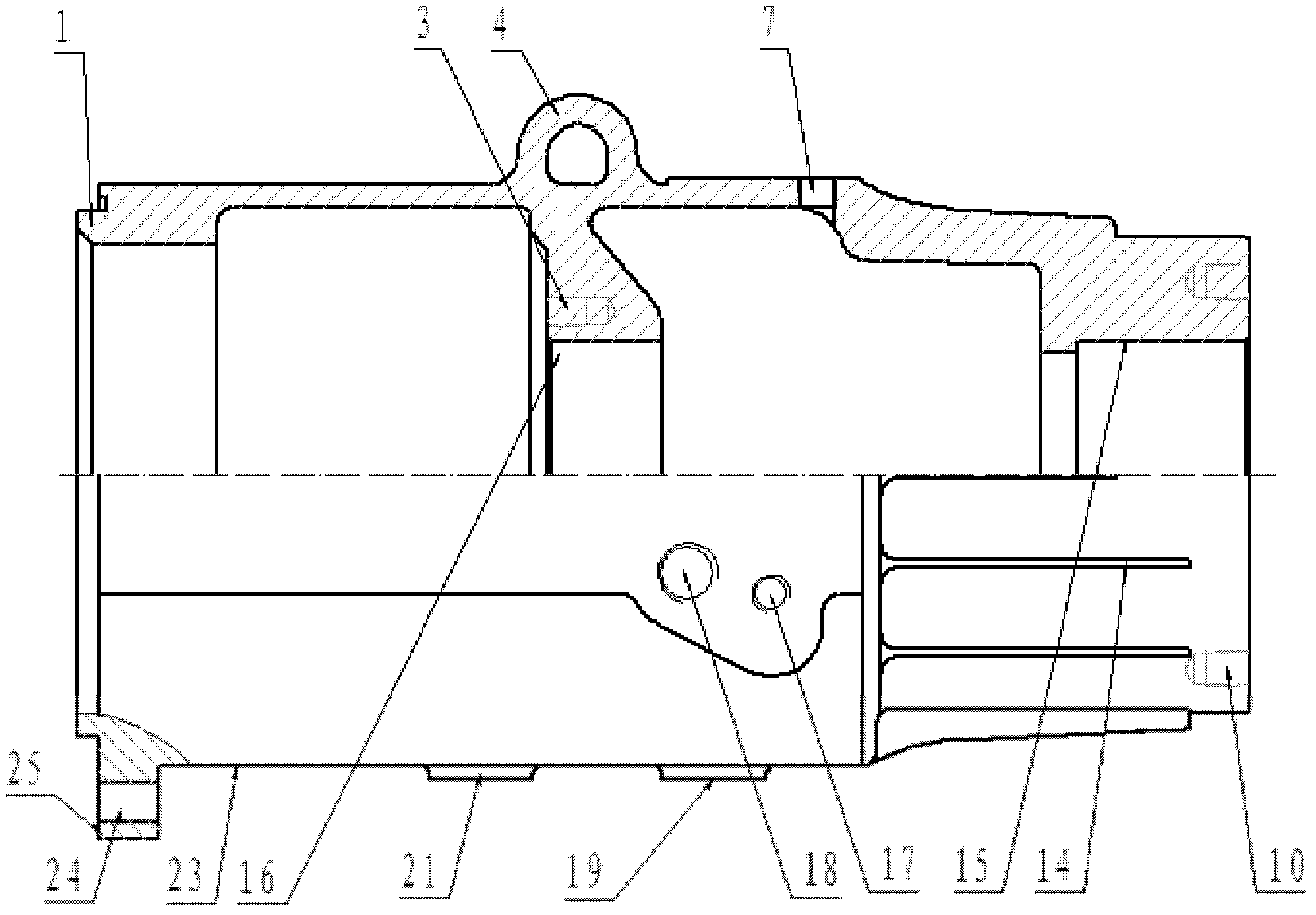

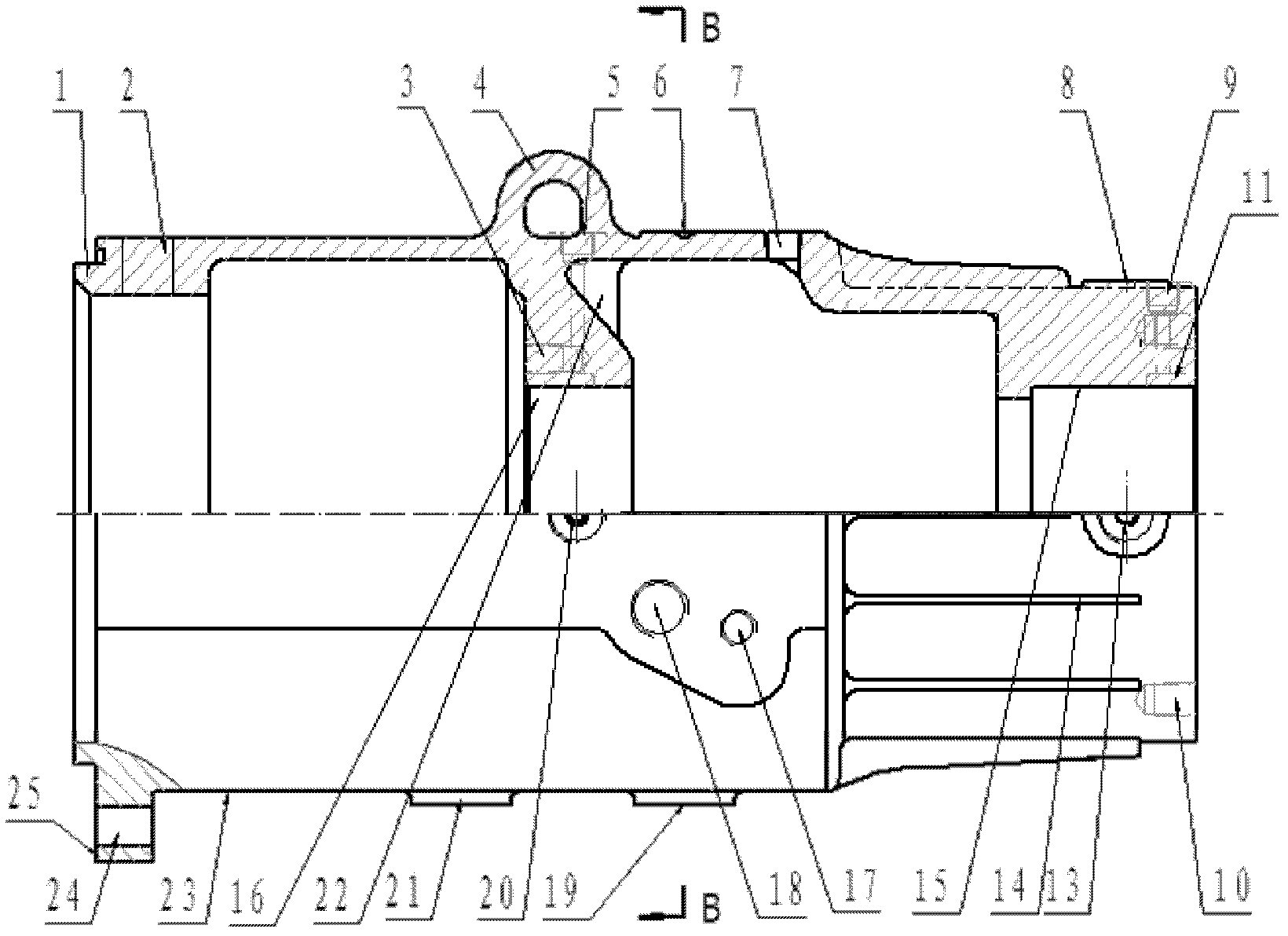

[0020] The octagonal closed bearing bracket connected with the housing proposed by the present invention has a structure such as figure 2 As shown, the shape of the bearing bracket body is three different shapes, and the cross-sectional shape of the front bearing bracket body is octagonal. Such as figure 2 In 23, the cross-sectional shape of the middle bearing bracket body is a semicircle connected with a half octagon, such as Figure 4 with Figure 5 shown in . The cross-sectional shape of the rear bearing bracket body is circular.

[0021] The structure of an embodiment of the octagonal closed bearing bracket of the present invention is as follows image 3 As shown, the front end of the bearing bracket body is provided with a connection end 25 for fixing with the housing, and a connection bolt hole 24 is provided on the connection end. The octagonal shell at the front of the bearing bracket body is provided with a drain hole 21 . A suspension ring 4 for equipment ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com