Remote control drilling and repairing equipment lifting device and application method

A lifting device and equipment technology, applied in the direction of lifting device, mechanical equipment, fluid pressure actuating device, etc., can solve the problems of many hidden dangers and low work efficiency, so as to avoid hidden dangers of personal safety, and solve the discomfort of mind and body. , the effect of easy remote operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

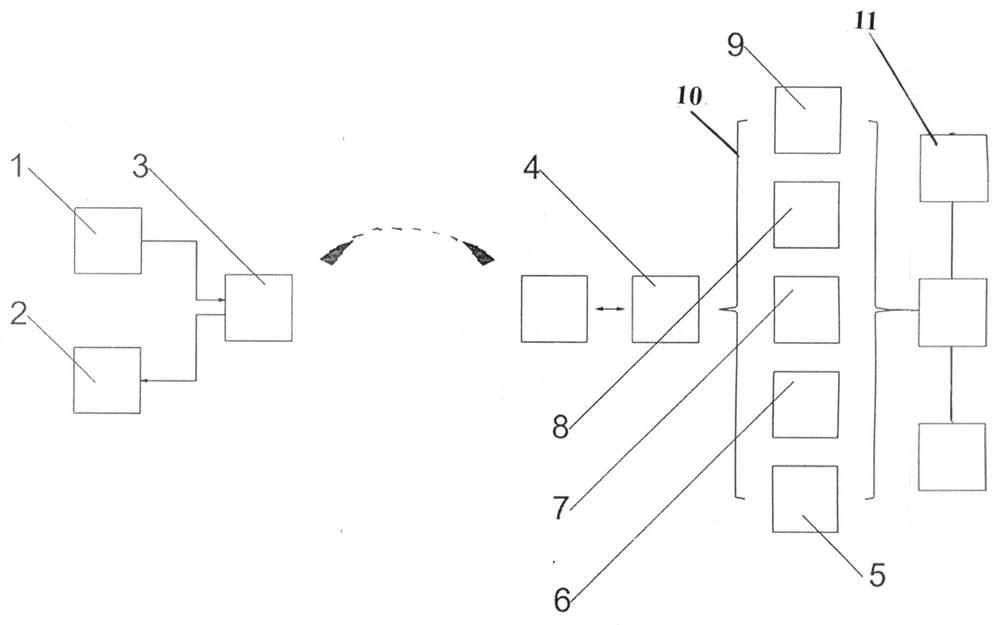

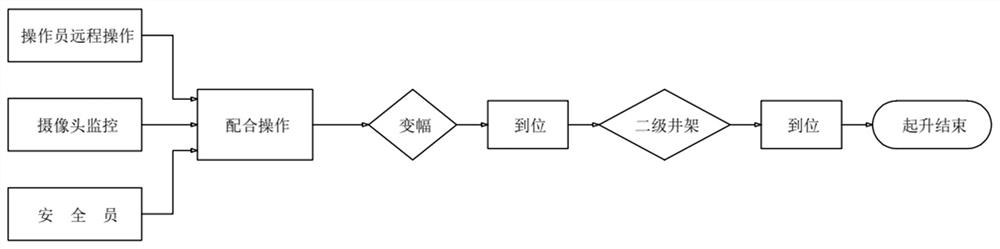

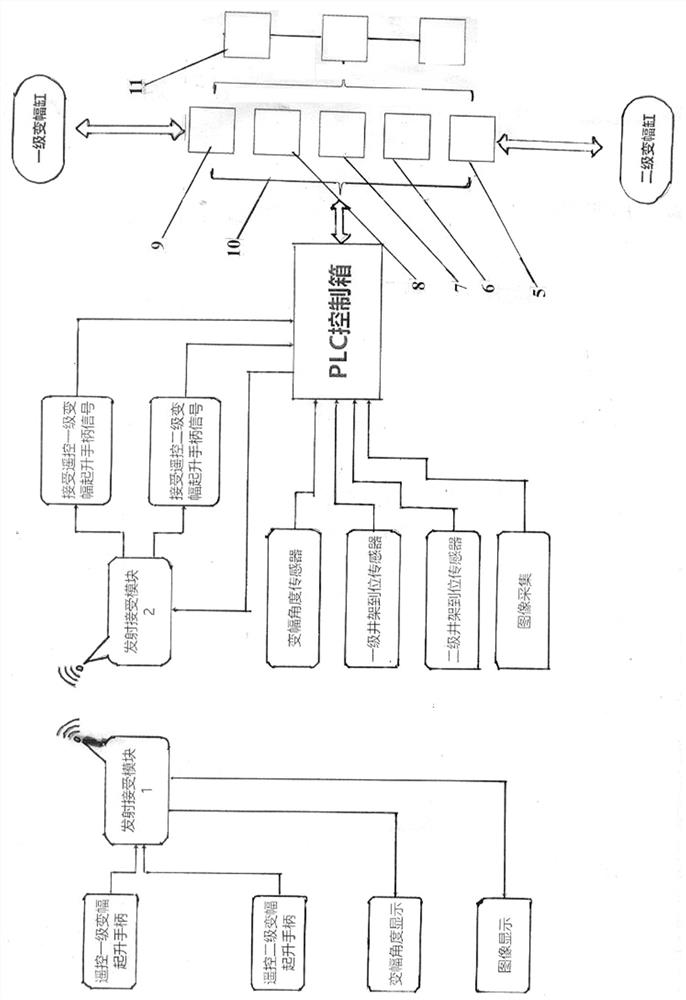

[0013] Embodiment 1. The present invention includes a remote lifting handle 1, a touch display screen 2, a remote transceiver module 3, a PLC control box 4, a high-definition explosion-proof camera 5, a proportional solenoid valve 6, an electromagnetic proportional electro-hydraulic reversing valve 7, and an electromagnetic proportional Relief valve 8, electromagnetic proportional overflow flow valve 9 10, hydraulic integrated block, described remote transceiver module 3 is provided with two pieces, and one end of its remote transceiver module 3 is connected with remote lifting handle 1, touch display screen 2, its The other end of the remote transceiver module 3 is connected to a PLC control box 4; the PLC control box 4 is connected to the hydraulic manifold 10; the hydraulic manifold 10 is connected to the drilling and repairing equipment 11.

Embodiment 2

[0014] Embodiment 2. The hydraulic manifold 10 is connected with a high-definition explosion-proof camera 5 , a proportional solenoid valve 6 , an electromagnetic proportional electro-hydraulic reversing valve 7 , an electromagnetic proportional overflow valve 8 and an electromagnetic proportional overflow flow valve 9 .

Embodiment 3

[0015] Embodiment 3. The hydraulic manifold 10 is connected to the first-stage luffing cylinder and the second-stage luffing cylinder respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com