Adjustable sizing block

A pad iron and washer technology, applied to the frame of the engine, supporting machines, mechanical equipment, etc., can solve the problems of heavy workload, increased production cost, waste of materials and stacking space, etc., and achieve the effect of easy operation and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

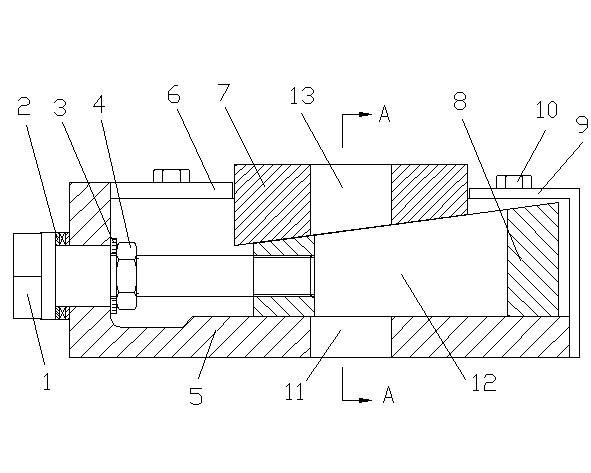

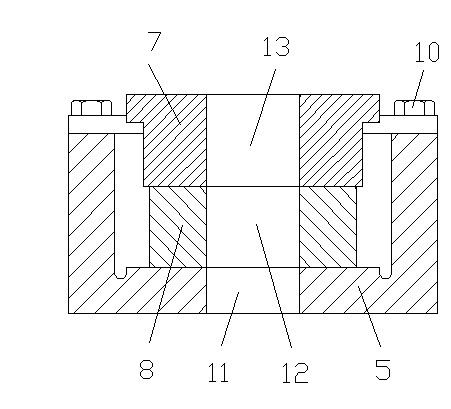

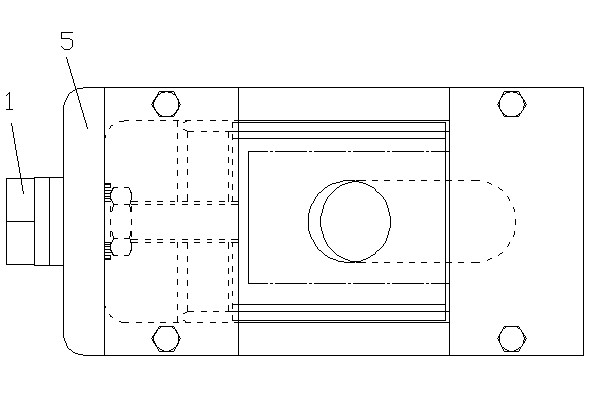

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through the examples. The following examples are to explain the present invention and the present invention is not limited to the following examples.

[0018] Example.

[0019] see Figure 1 to Figure 3 , The adjustable pad iron in this embodiment includes an adjusting screw 1 , a thrust bearing 2 , a washer 3 , a tightening nut 4 , a base 5 , a lifting wedge 7 and a sliding block 8 .

[0020] The base 5 in this embodiment includes a bottom plate, two side plates, an adjusting screw support plate, a baffle 6 and a stopper 9, wherein the two side plates are respectively fixed on both sides of the bottom plate, and the adjusting screw supporting plate is fixed on the bottom plate , the two sides of the adjusting screw support plate are respectively fixed with the two side plates. The stopper 9 in this embodiment is a structure in which the "L" character is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com