Dustproof and ventilation system of automatically cleaning filter screen in machine room

A ventilation system and automatic cleaning technology, applied in heating and ventilation control systems, heating and ventilation safety systems, dispersed particle filtration, etc., can solve problems such as inconvenient cleaning, poor ventilation, and restrictions on popularization and use, so as to reduce maintenance and avoid To clean the filter and reduce the effect of running times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, technical solution of the present invention is described further:

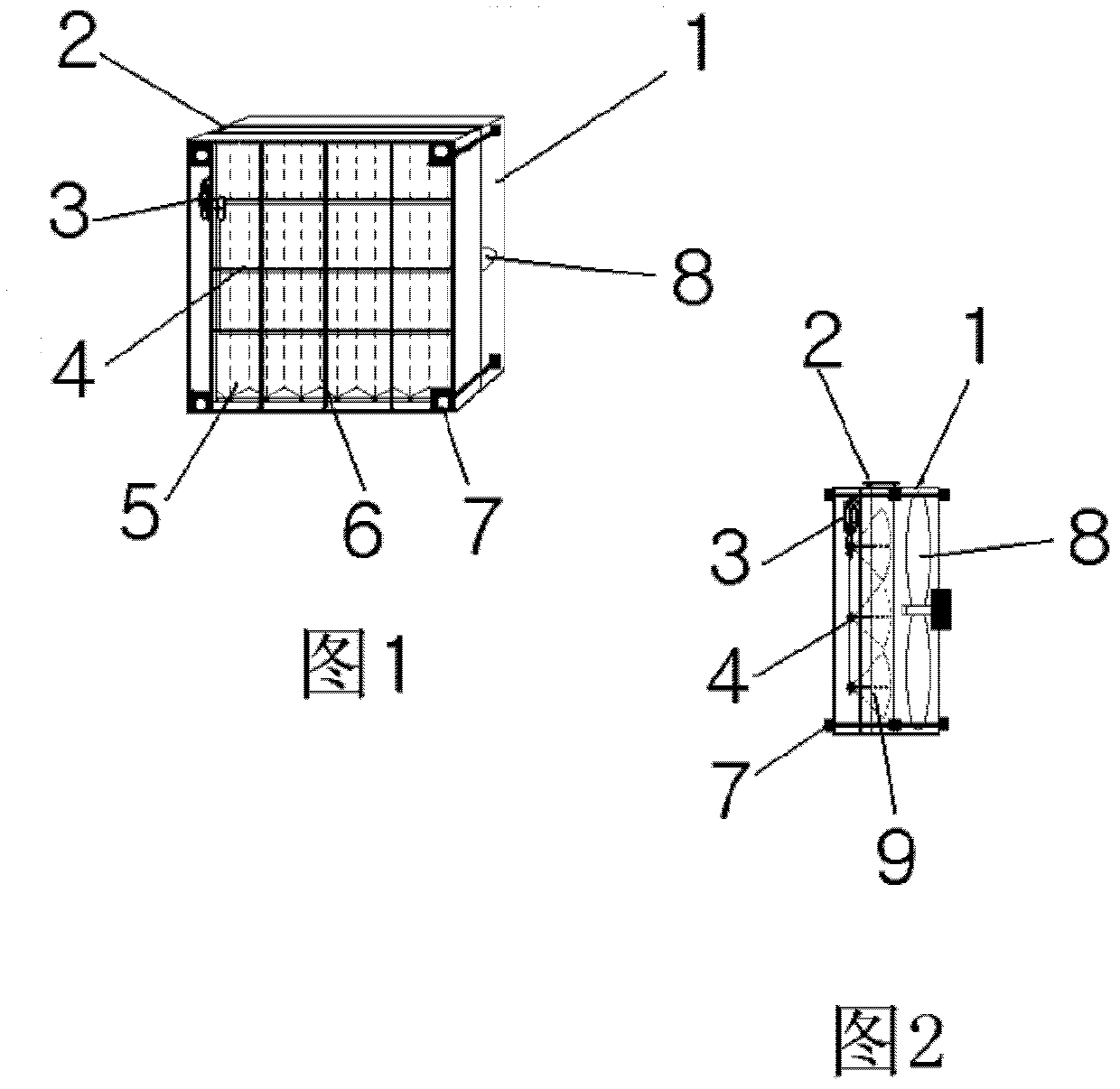

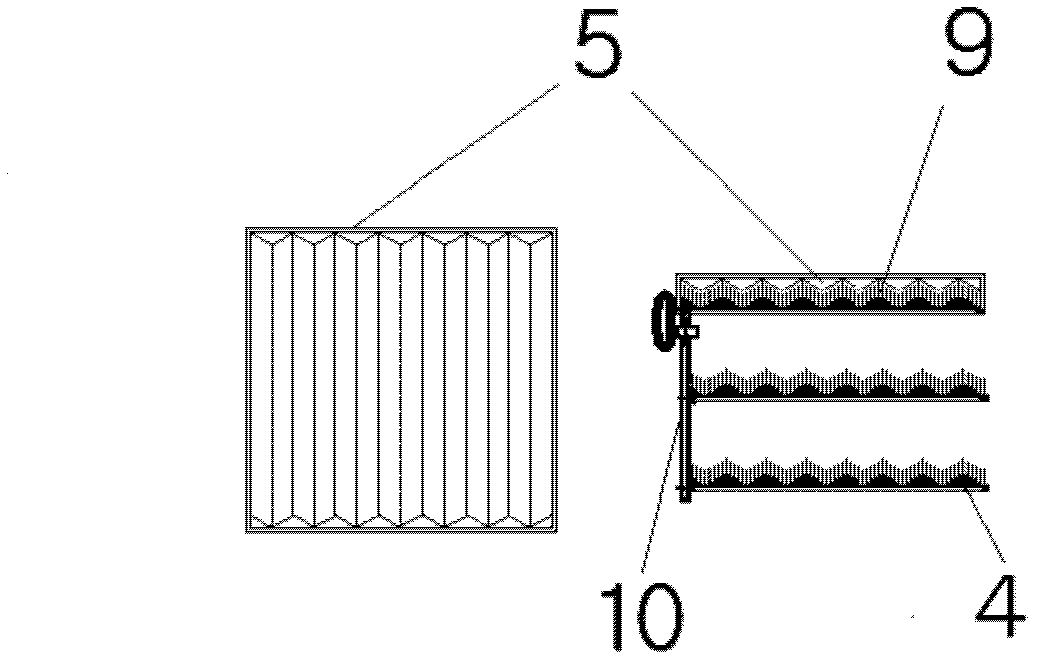

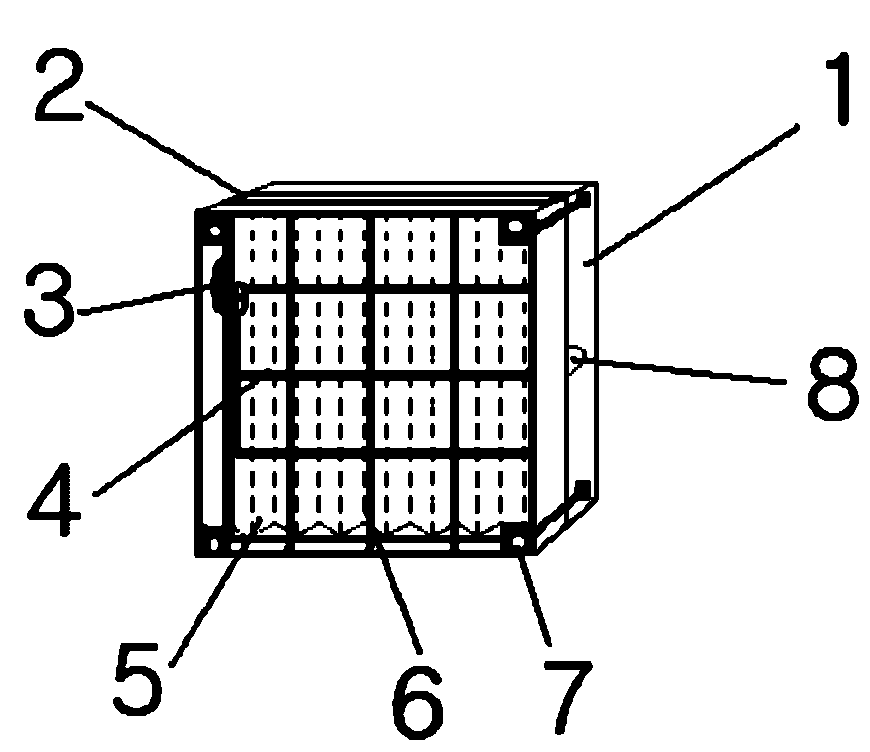

[0015] exist Figure 1 to Figure 3 Among them, the stepper motor (3), the guide bar (4), the pleated filter screen (5), the anti-theft steel bar (6), the combination screw (7), the fan blade (8 ), the serrated row brush (9), the swing arm guide rod (10) and the fan motor, the guide bar (4) connected to the sawtooth row brush (9) is connected to the left and right sides of the return air outlet frame (1), and the return air outlet frame (1) The upper or lower part is provided with a filter mesh inlet, and the pleated filter mesh (5) is connected with the handle (2) and placed in the return air outlet frame (1). The sawtooth row brush (9) connected to the inner surface of the tuyere frame (1) drives the guide bar (4) through the swing arm guide rod (10) to clean the pleated filter screen (5) by moving up and down, and the automatic cleaning filter screen T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com