Oil cooler

A technology for oil coolers and oil passages, applied in heat exchanger types, indirect heat exchangers, installation, etc., can solve the problems that the positions of outflow holes and inflow holes may not be consistent, and achieve manufacturing cost reduction, manufacturing cost reduction, The effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

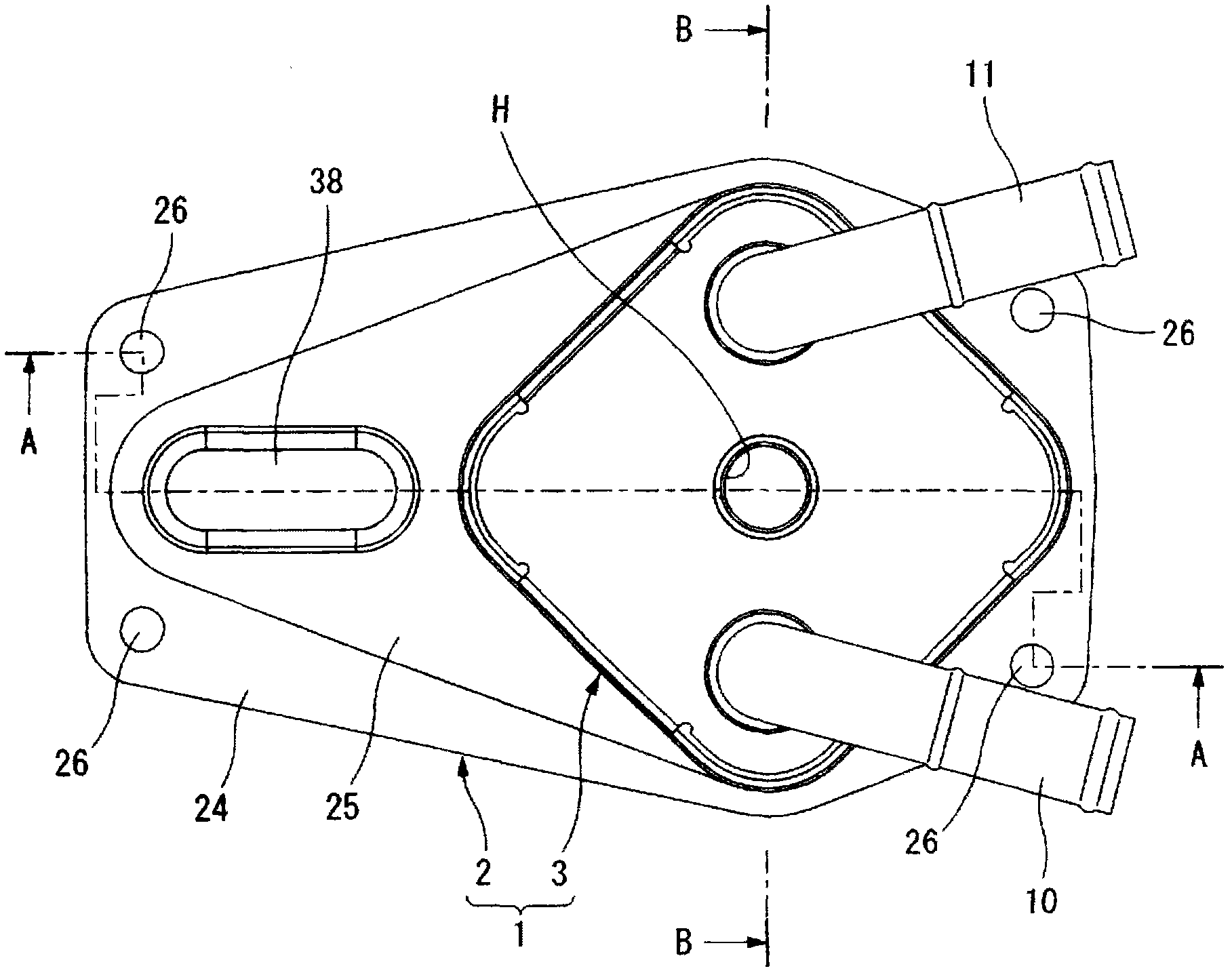

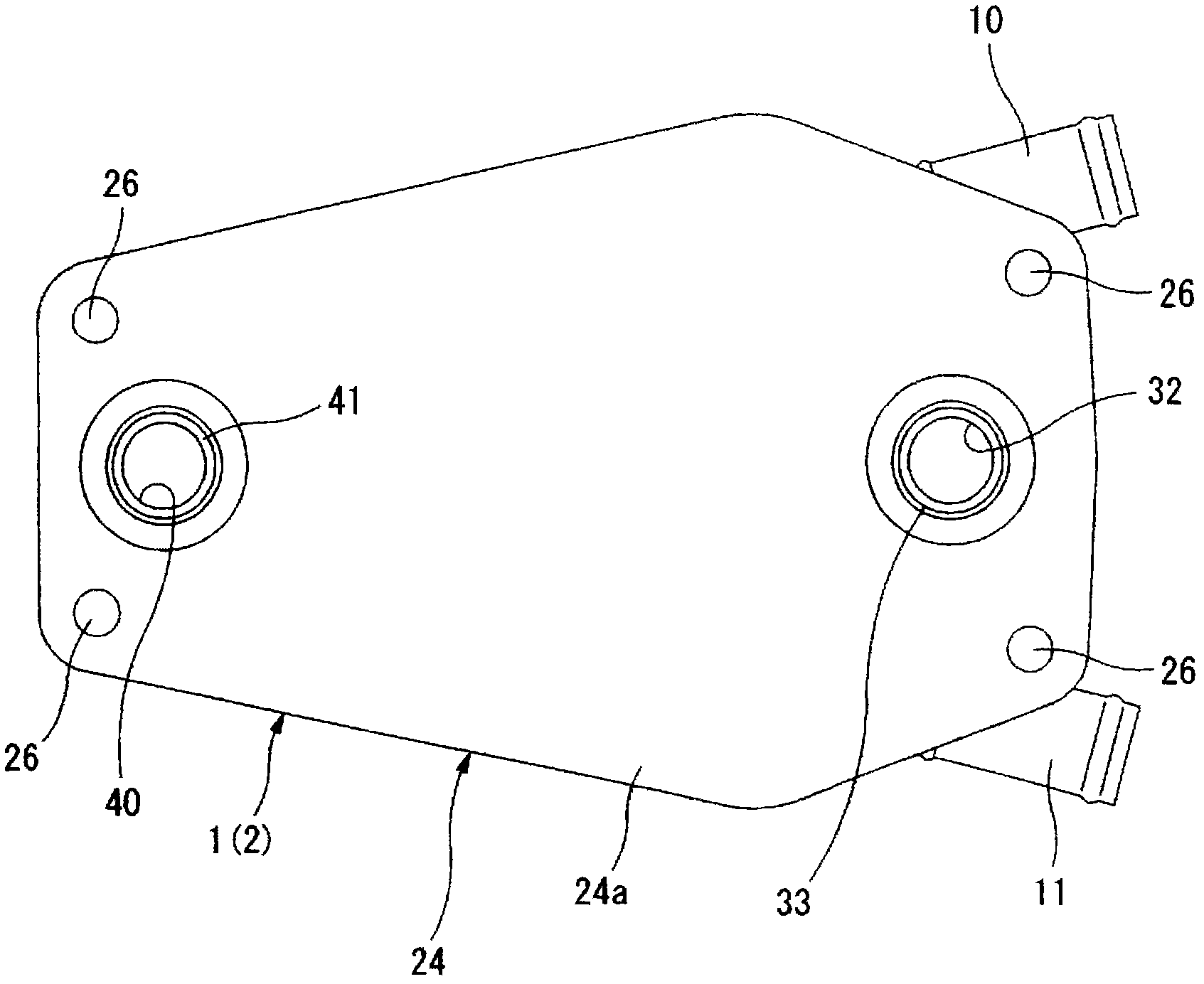

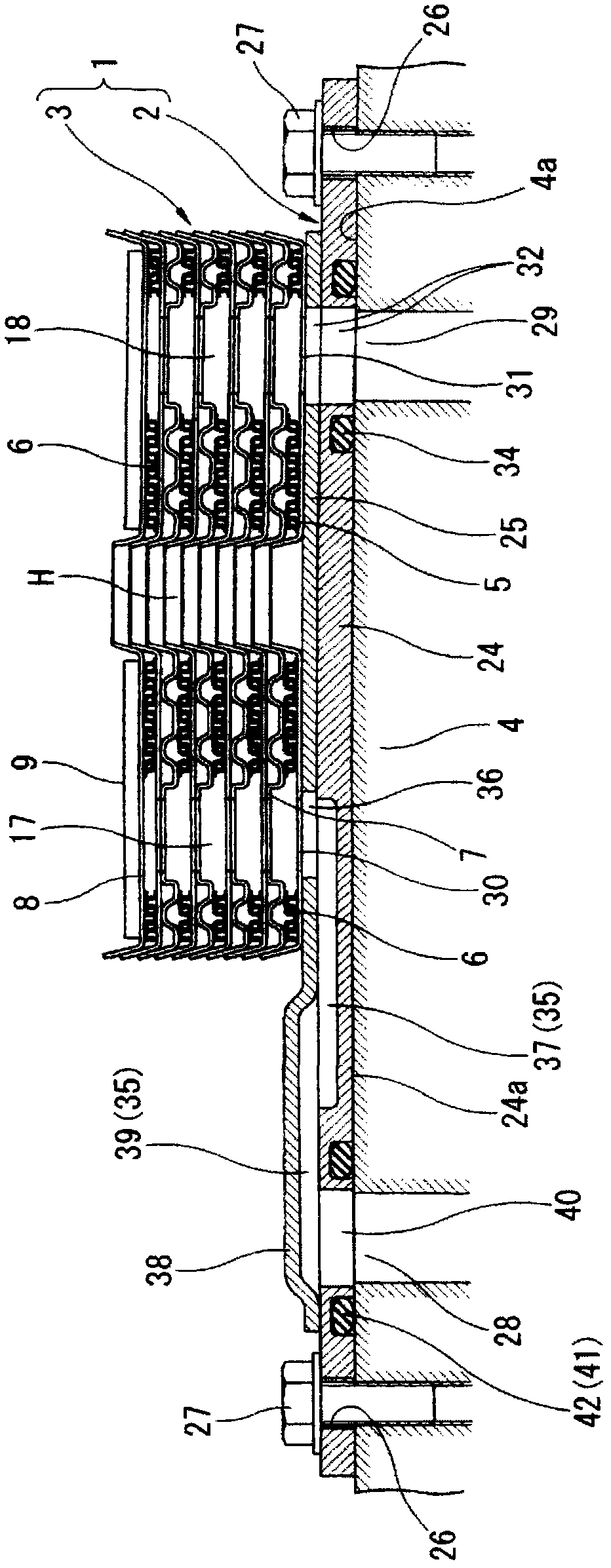

[0084] Figures 1 to 7 is a view showing a more specific embodiment for carrying out the oil cooler according to the invention, figure 1 shows the top view of the oil cooler, figure 2 Bottom view showing the same oil cooler. also, image 3 Indicated as the installed state of the above oil cooler along the figure 1 A sectional view of the A-A line, Figure 4 An exploded view showing the same oil cooler.

[0085] Such as figure 1 , 2 as well as image 3 As shown, the oil cooler 1 is composed of a laminated core 3 formed by laminating a core plate 5 , a radiator plate 6 , and an embossed plate 7 described later in multiple layers with a predetermined regularity; It is composed of two superimposed substrates 2 superposed thereon. The laminated core 3 functions as a heat exchange part as will be described later, and the substrate 2 functions as a mounting flange part for a transmission case 4 of an automatic transmission, which is a counterpart device, for example. And, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com