Method for preventing microscope on Cascade probe station from striking probe

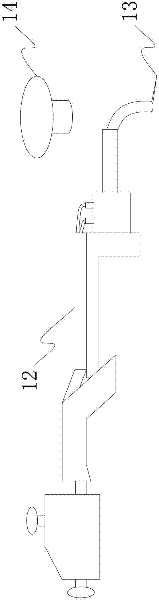

A technology of microscope and probe station, applied in the direction of instruments, alarms, etc., can solve the problems of deformation of the needle seat beam 12, the falling height of the microscope barrel 14, and the deformation of the beam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

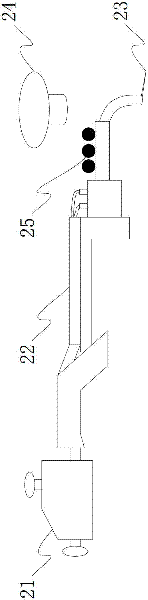

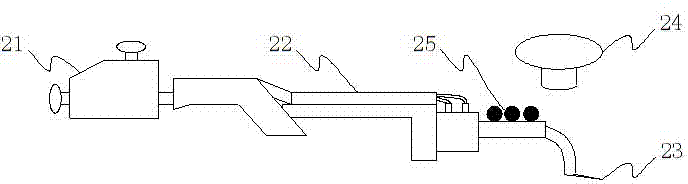

[0012] figure 2 It is a structural schematic diagram of a method for preventing Cascade probe station microscope striker according to the present invention.

[0013] Such as figure 2 As shown, the probe 23 is arranged on the base 21 through the crossbeam 22. A method of preventing the Cascade probe station microscope from striking the needle of the present invention, the sensor 25 is arranged at the position of the crossbeam 22 close to the probe 23, and a warning device (in the figure Not shown) communicates with the sensor 25, when the microscope barrel 24 is too close to the probe 23, before the microscope barrel 24 does not touch the crossbeam 22, the sensor 25 will send a signal to the warning device, and the warning device will send out a sound or a signal light, etc. way to warn the operator of the microscope to prompt him to stop the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com