Preparation method for improving performance of industrial silicon thin-film cell component

A technology for battery components and silicon thin films, applied in electrical components, final product manufacturing, circuits, etc., to reduce pollution, improve battery efficiency, and improve photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

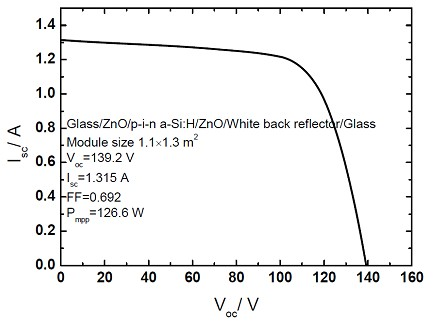

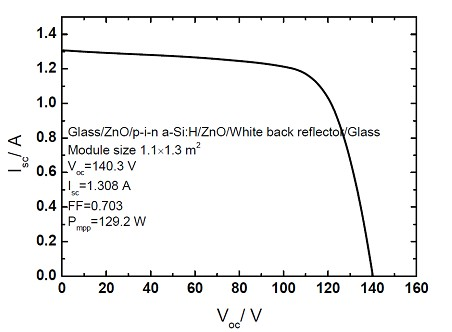

[0013] This embodiment is to prepare a single-junction p / i / n type amorphous silicon thin-film solar cell, and use pre-deposited amorphous silicon thin film to reduce the pollution of the cell and improve the photoelectric conversion efficiency of the cell.

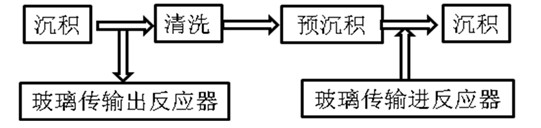

[0014] The present invention comprises the following steps:

[0015] First, transfer the deposited pin-type silicon thin film battery from the reaction chamber to the outside of the reaction chamber;

[0016] Second, use the plasma-enhanced chemical vapor deposition process to control the deposition power and the concentration of nitrogen trifluoride, and perform fluorine plasma etching and cleaning on the reaction chamber after the deposition of the battery;

[0017] Third, plasma-enhanced chemical vapor deposition is used to control the deposition power and silane concentration to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com