Integrated control system for arc suppression coil

An arc suppressing coil and integrated control technology, which is applied in the field of measurement and control of electrical technology, can solve the problems of inability to control neutral point displacement voltage, cumbersome measurement process, and resonance overvoltage, so as to achieve a small impact on system operation and a wide range of applications , easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

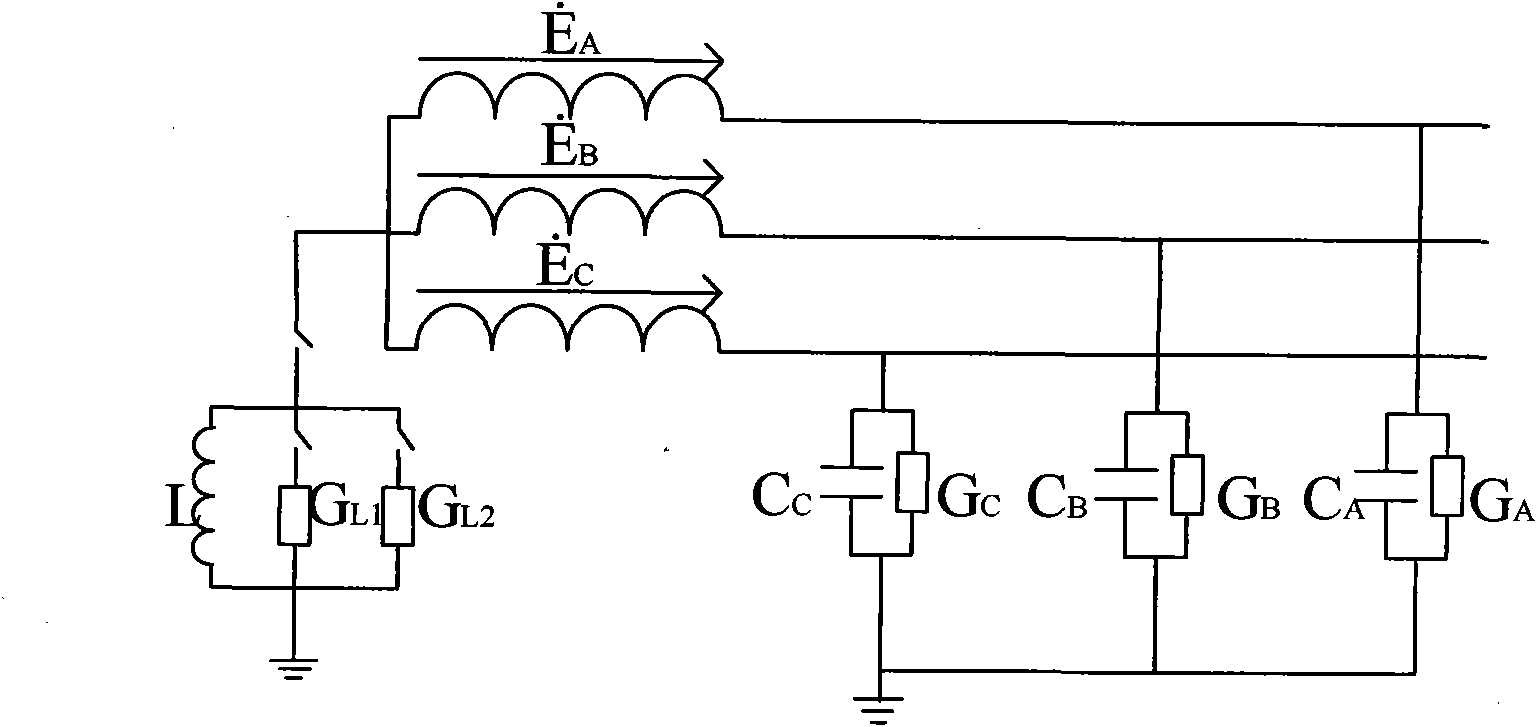

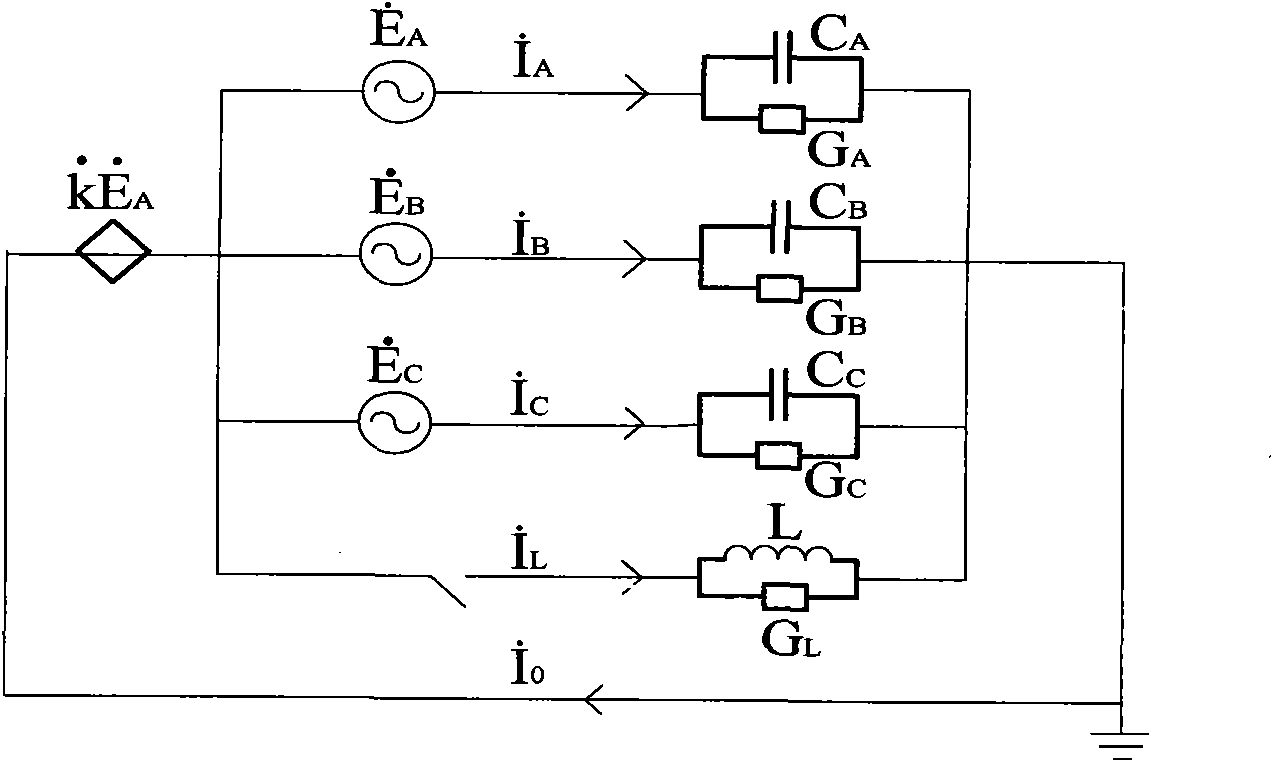

[0050] Embodiment 1: Comprehensive control steps of the adjustable arc suppression coil.

[0051] Step 1: The adjustable arc suppression coil often does not work with damping, so the damping conductance G is connected in parallel at both ends of the arc suppression coil L1 , measure the effective value U of the zero-sequence voltage under this damped conductance 01 and phase

[0052] Step 2: The controller changes the damping conductance to G L2 , re-measure the effective value U of the zero-sequence voltage 02 and phase

[0053] Step 3: Cut off the parallel damping of the arc suppression coil.

[0054] Step 4: Calculate the total capacitance and conductance of the system and the tuning of the arc suppression coil according to the known quantities.

[0055] Detuning amount Y LC =ωC ∑ -1 / (ωL X )for:

[0056] Formula 1

[0057] The total conductance of the system is:

[0058] Formula 2

[0059] In the formula is the phase difference of the zero-sequence vol...

Embodiment 2

[0072] Embodiment 2: Comprehensive control steps of the pre-adjusted arc suppression coil.

[0073] Step 1: Since the pre-adjusted arc suppression coil often does not work with damping, measure the damping conductance G L1 The effective value U of the lower zero sequence voltage 01 and phase

[0074] Step 2: The controller changes the damping conductance connected in parallel at both ends of the arc suppression coil to G L2 , re-measure the effective value U of the zero-sequence voltage 02 and phase

[0075] Step 3: Calculate the total capacitance and conductance of the system and the tuning of the arc suppression coil according to the known quantities.

[0076] Detuning amount ωC ∑ -1 / (ωL X )for:

[0077] Formula 7

[0078] The total conductance of the system is:

[0079] Formula 8

[0080] In the formula is the phase difference of the zero-sequence voltage.

[0081] The total capacitance of the system to ground is calculated from the detuning amount as: ...

Embodiment 3

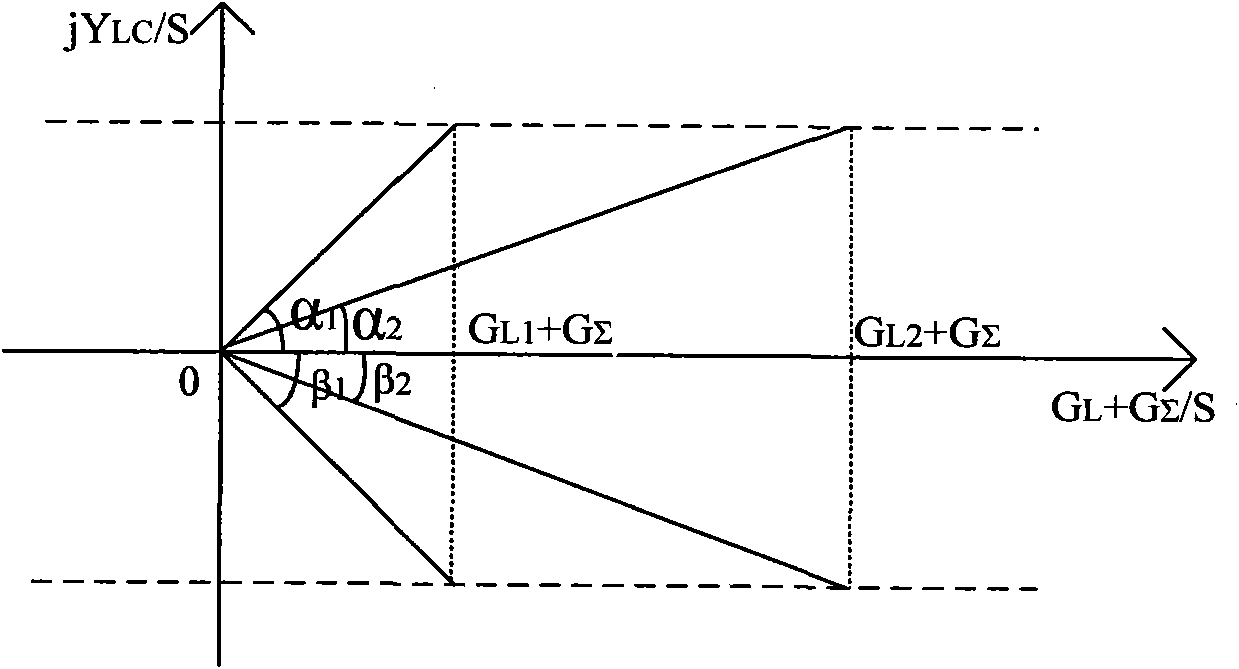

[0096] Embodiment 3: Control steps of arc suppressing coil tuning and limiting neutral point displacement voltage regardless of conductance.

[0097] Step 1: For the preset ignore system, the resistance adjustment measurement of the total conductance arc suppression coil to the ground is the same as step 1, step 2 and step 3 of embodiment 1; Step 1 and Step 2 of Example 2 are the same.

[0098] Step 2: Determine the working state of the arc suppression coil, that is, whether it is under-compensated or over-compensated. G L Increase as an example, detect the phase angle of the neutral point voltage. if It can be judged that the arc suppression coil is undercompensated; if It can be judged that the arc suppressing coil is overcompensated.

[0099] Step 3: Tuning of the crowbar after ignoring the system conductance. The system detuning amount is:

[0100] Y LC = ± ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com