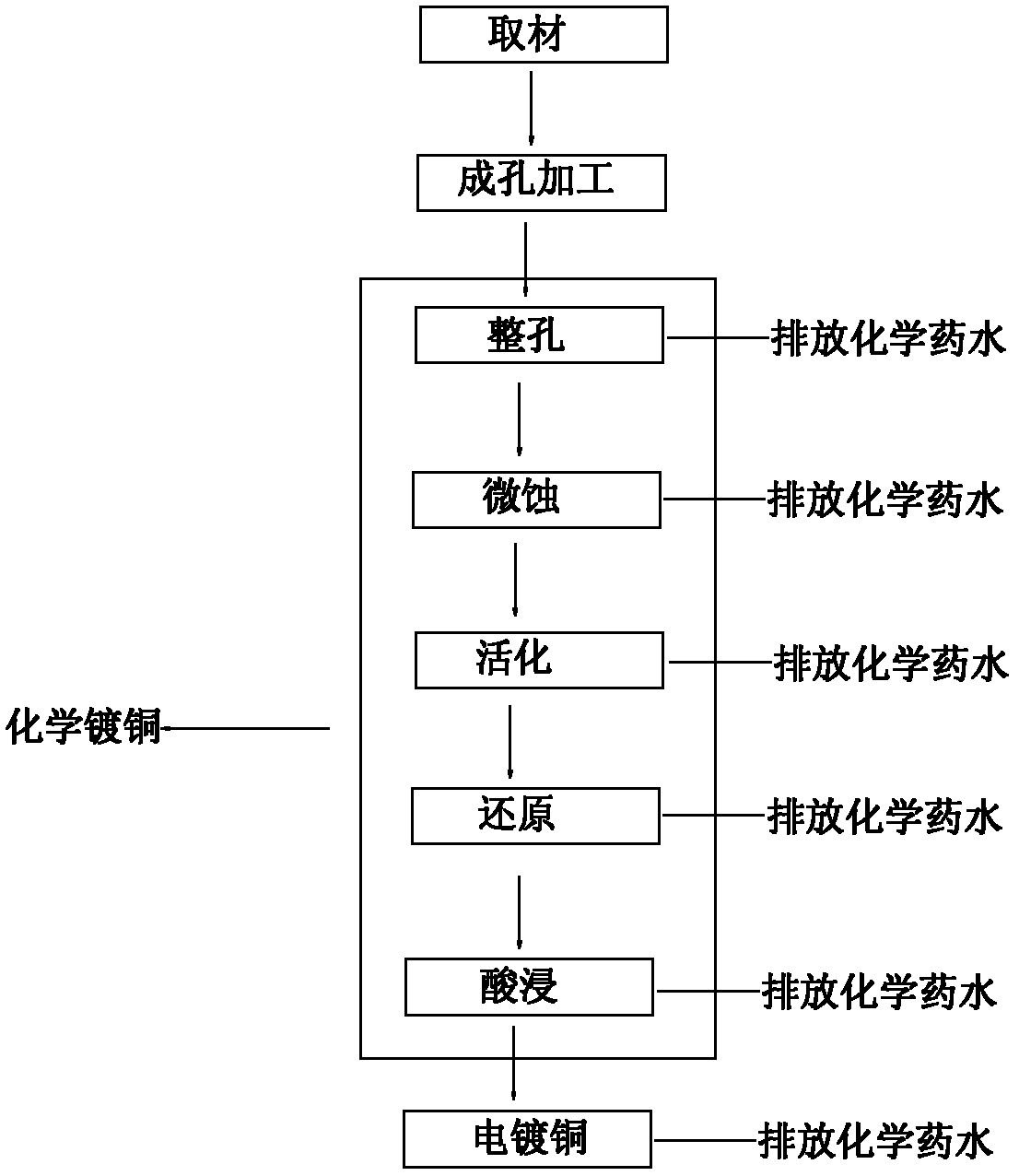

Manufacturing process of interlayer copper connector of printed circuit board

A technology for printed circuit boards and manufacturing processes, which is applied in the direction of electrical connection formation of printed components to achieve the effects of reducing the total investment, reducing investment risks, and shortening the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

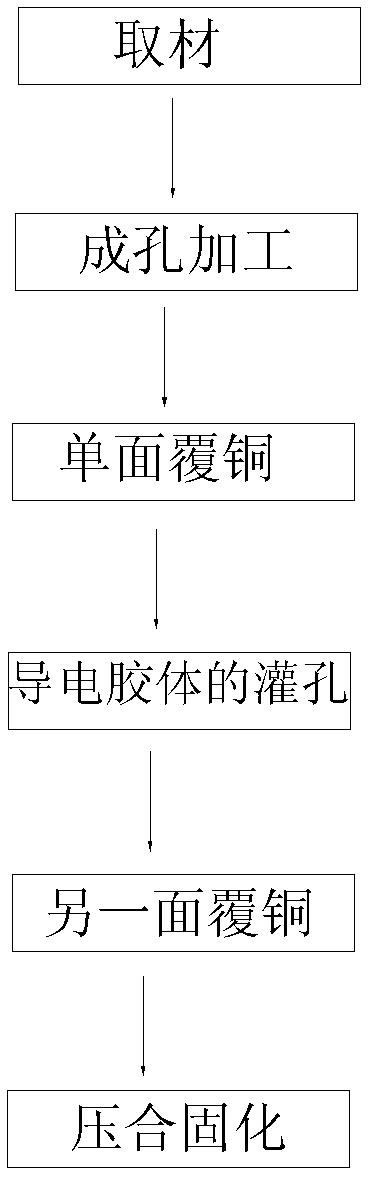

[0040] This embodiment provides a manufacturing process for interlayer copper connections of printed circuit boards, such as figure 2 shown, including the following steps:

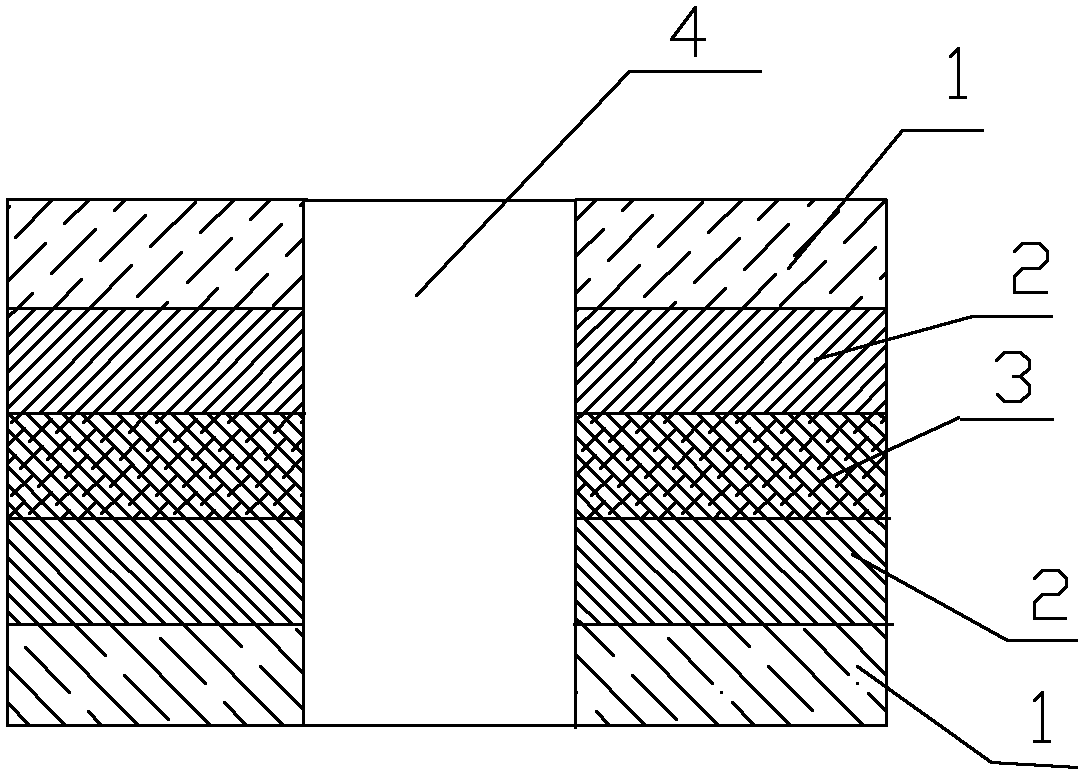

[0041] Step 1: Take materials: Coat the adhesive resin layer on both sides of the outer surface of the insulating layer, and then glue and press the release paper on both sides of the outermost outer surface;

[0042] Take the insulating layer 3 made of glass fiber resin, with a thickness of 12.5 μm, and coat the adhesive resin layer 2 made of acrylic resin glue on the outer surface of the insulating layer 3. The thickness of the adhesive resin layer 2 is 10 μm, the speed of the coating machine is 4m / min, the temperature of the drying tunnel is 60°C, after preliminary drying in the drying tunnel, apply the adhesive resin layer 2 made of acrylic resin glue on the other side again, and repeat the previous coating operation The procedure is to stick and press the release paper 1 on the outer surface of the ...

Embodiment 2

[0060] This embodiment provides a manufacturing process for interlayer copper connections of printed circuit boards, such as figure 2 shown, including the following steps:

[0061] Step 1: Collect materials

[0062] Take the insulating layer 3 made of polyimide PI film, with a thickness of 200 μm, and coat the adhesive resin layer 2 made of modified acrylic resin glue on the outer surface of the insulating layer 3, the adhesive resin layer The thickness of 2 is 100 μm, the speed of the coating machine is 4m / min, and the temperature of the drying tunnel is 60°C. After preliminary drying in the drying tunnel, the adhesive resin layer 2 made of modified acrylic resin glue is coated again on the other side, and repeated In the previous coating operation procedure, the release paper 1 was glued and pressed on both sides of the outermost layer of the double-sided outermost layer, the pressure was 6MPa, and the temperature was 80°C.

[0063] Step 2: Hole forming;

[0064] Then ca...

Embodiment 3

[0079] This embodiment provides a manufacturing process for interlayer copper connections of printed circuit boards, such as figure 2 shown, including the following steps:

[0080] Step 1: Collect materials

[0081] Get the insulating layer 3 made of polyester PET film, its thickness is 80 μ m, the adhesive resin layer 2 that is made of epoxy resin glue is coated on the outer surface of the insulating layer 3, the adhesive resin layer 2 The thickness is 50μm, the speed of the coating machine is 4m / min, and the temperature of the drying tunnel is 60°C. After preliminary drying in the drying tunnel, the adhesive resin layer 2 made of epoxy resin glue is coated again on the other side, and the previous coating is repeated. Overlapping operation procedure, double-sided sticking and pressing release paper 1 on the outer surface of the double-sided outermost layer, the pressure is 6MPa, and the temperature is 80°C.

[0082] Step 2: Hole forming;

[0083] Drilling is then carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com