Automatic weighing and sorting device

A sorting device and automatic weighing technology, applied in sorting and other directions, can solve the problems of low efficiency and long completion time, and achieve the effects of high efficiency, providing efficiency and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to solve the problem of slow beat and low efficiency of traditional automatic weighing and sorting devices, a self-weighing and sorting device and method with fast beat and high efficiency are provided.

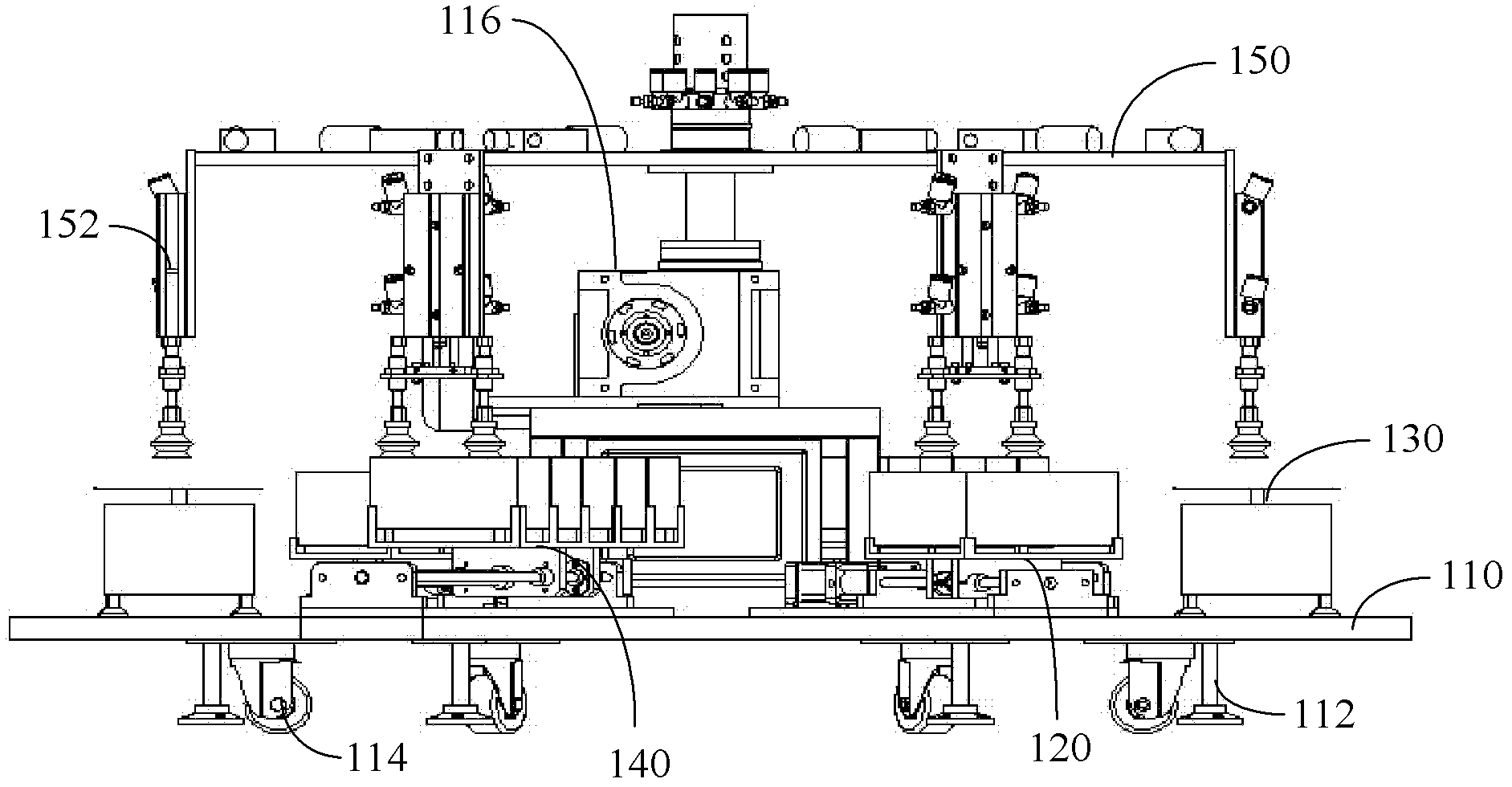

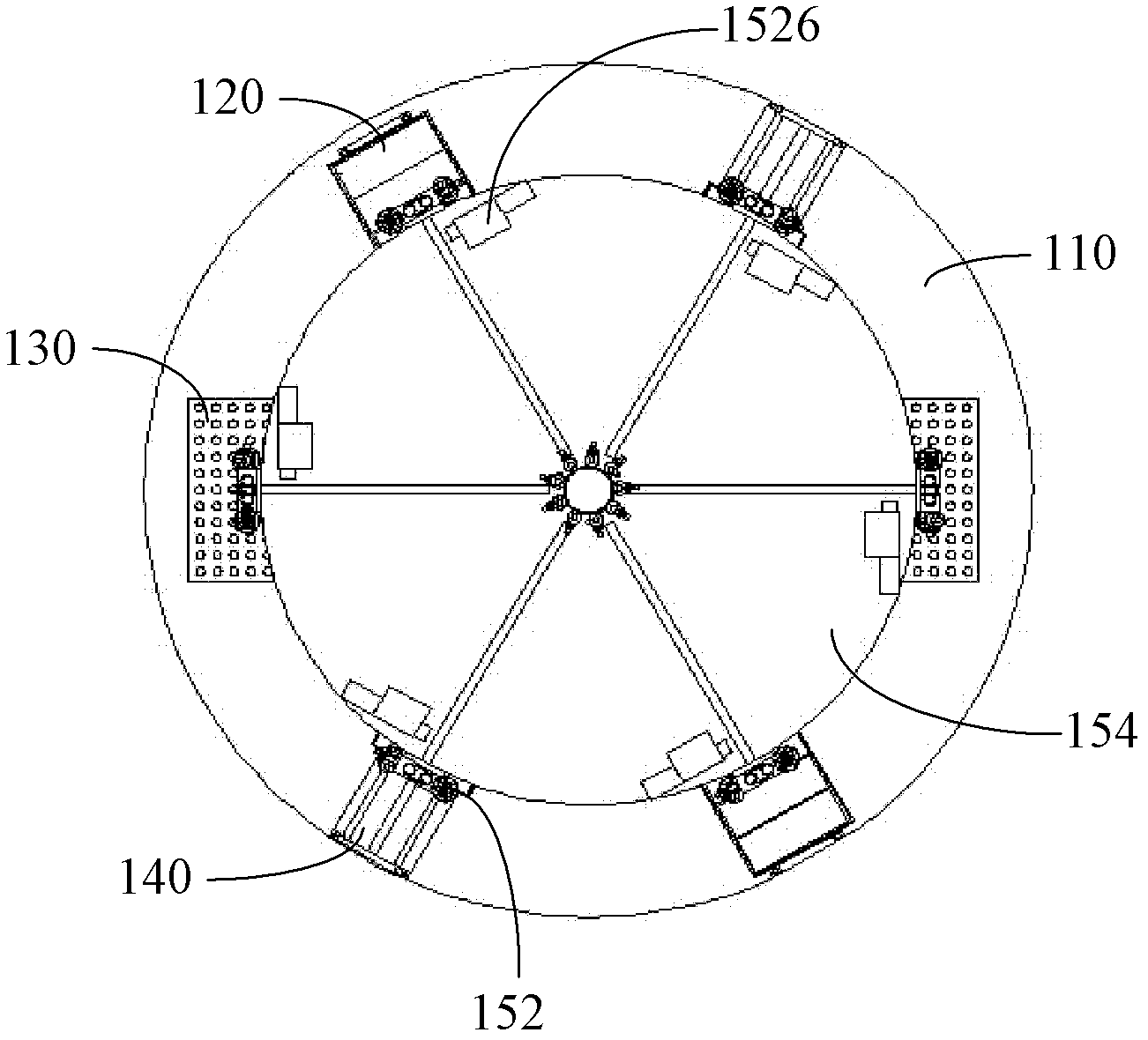

[0029] Such as figure 1 As shown, an automatic weighing and sorting device in one embodiment includes a frame 110 , a loading assembly 120 , a load cell 130 , an unloading assembly 140 and a handling assembly 150 .

[0030] The frame 110 is provided with a feeding station, a weighing station and a sorting station. The frame 110 is used for carrying the loading assembly 120 , the load cell 130 , the unloading assembly 140 and the handling assembly 150 . Usually, the loading station, weighing station and sorting station are arranged in sequence. The lower end of the frame 110 is provided with a leg 112 , and one end of the leg 112 in contact with the ground is provided with a mounting hole for fixing the frame 110 . Rollers 114 may also be provided at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com