Manufacturing and machining equipment used for hollow guide rail

A technology of hollow guide rails and processing equipment, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of increasing intermediate links and unfavorable assembly line production needs, and achieve the effect of improving production efficiency and reducing human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

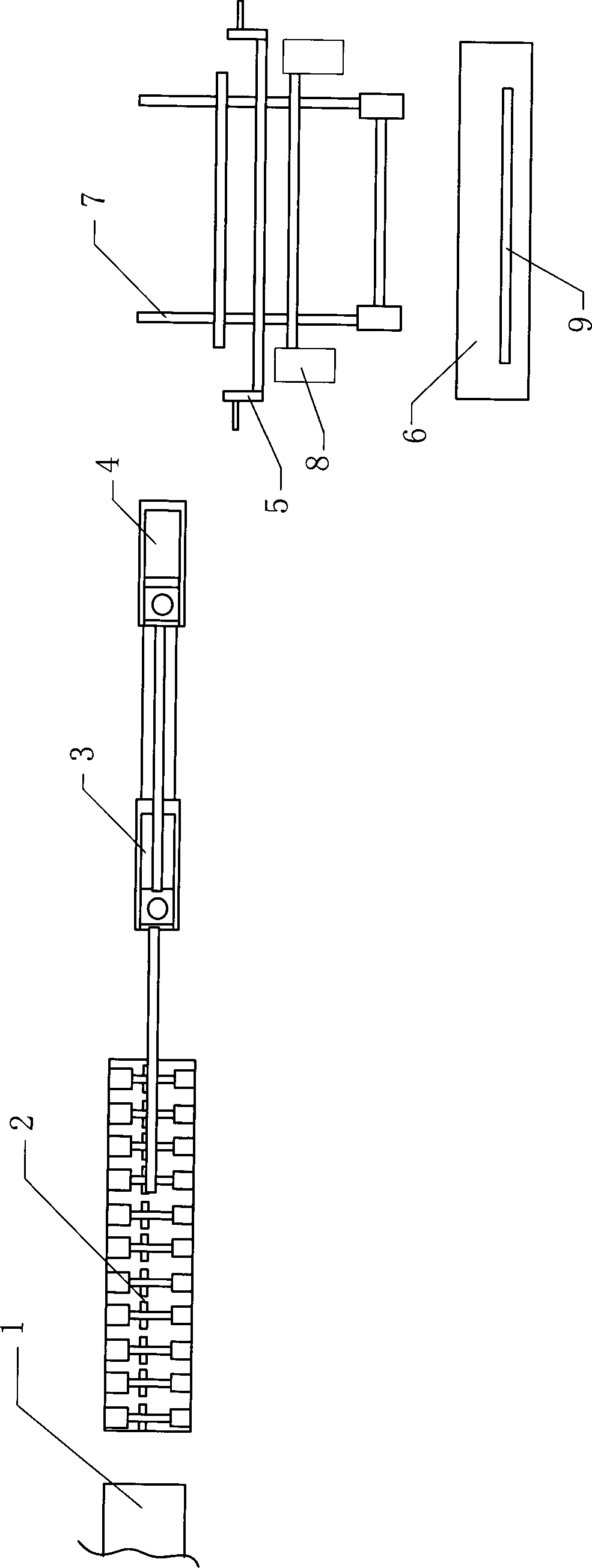

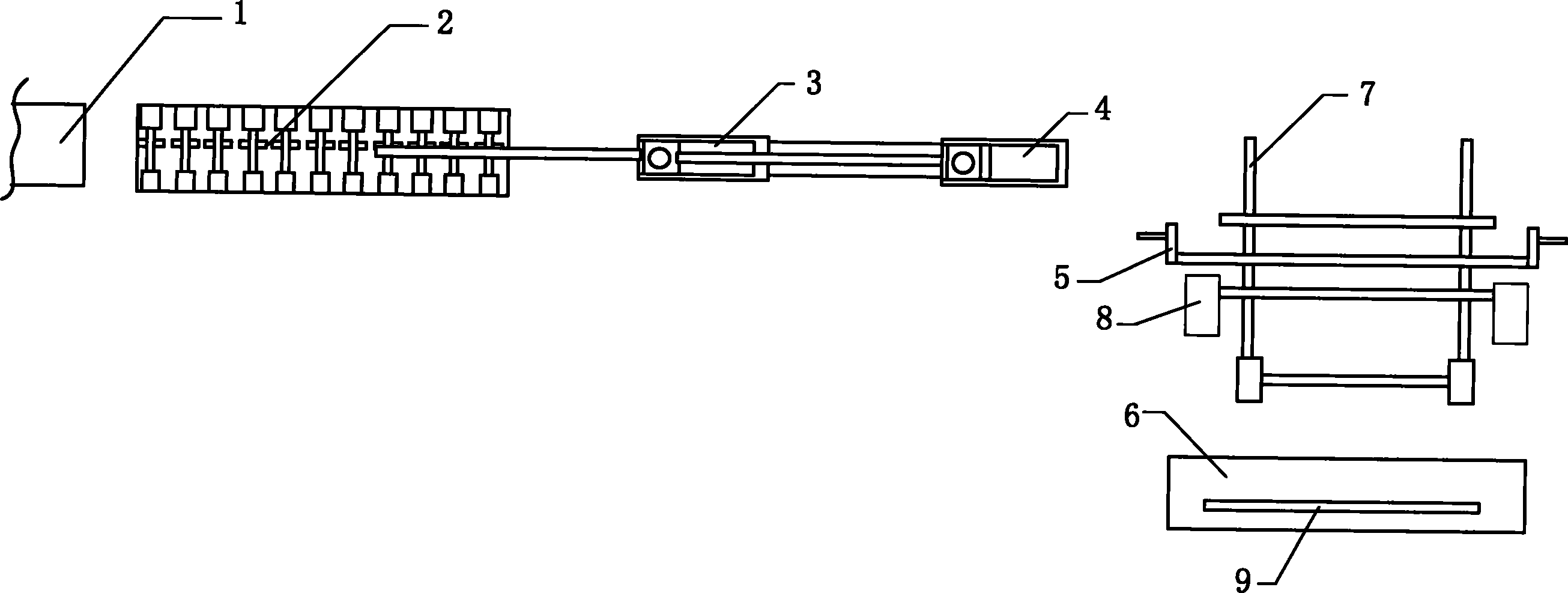

[0018] Such as figure 1 The shown manufacturing and processing equipment for hollow guide rail includes a hollow guide rail raw material conveying assembly 1 , which is different in that: the conveying end of the raw material conveying device used in the present invention is provided with a rolling assembly 2 . Specifically, a punching assembly 3 is provided at the delivery end of the rolling assembly 2 . Correspondingly, a cutting assembly 4 is installed at the delivery end of the punching assembly 3 . Furthermore, a deburring unit 5 is provided at the delivery end of the cutting unit 4 . At the same time, a stacker assembly 6 is placed on the delivery end of the deburring assembly 5 .

[0019] In view of a preferred embodiment of the present invention, considering that the length of the commonly used hollow guide rail 9 is relatively long, if a linear transmission is adopted after the cutting process, it will easily affect the subsequent deburring process. At the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com