Print fabric and color fabric preparation method

A manufacturing method and technology of printed cloth, applied in chemical instruments and methods, printing, synthetic resin layered products, etc., can solve the problems of long production time, high cost, reduced order quantity, etc., and achieve enhanced washing and dyeing fastness. , Environmentally friendly and clean production characteristics, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments. It should be understood that these embodiments are for illustration purposes only, and in no way limit the protection scope of the present invention.

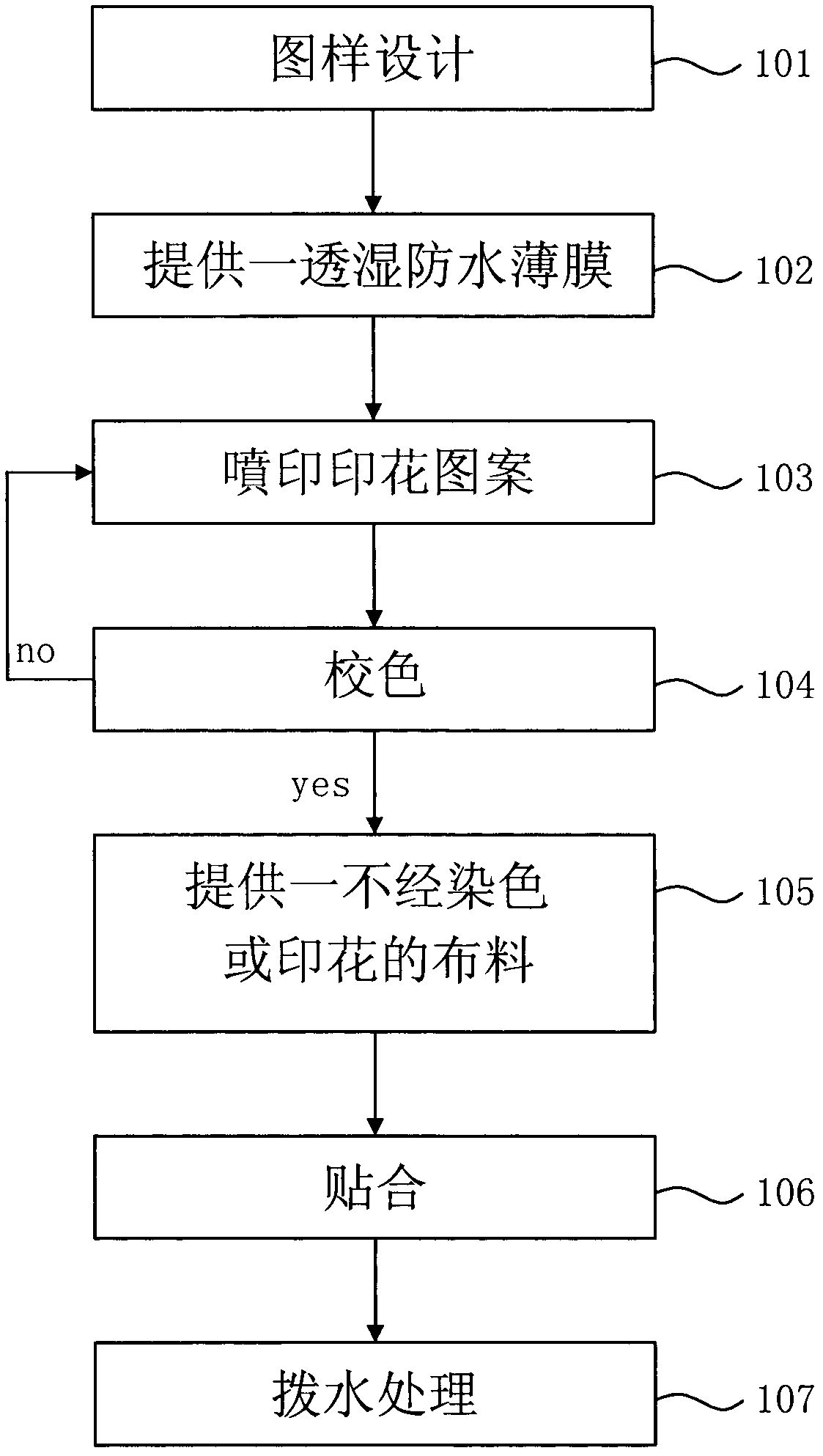

[0039] figure 2 It is a schematic diagram drawn according to an embodiment of the method for manufacturing printed cloth and colored cloth of the present invention. Such as figure 2 Shown, the printed cloth of the present embodiment and the color cloth manufacturing method comprise the following steps:

[0040] Step one 101, designing a pattern;

[0041] Step 2 102, providing a moisture-permeable waterproof film, which can be one of a non-porous hydrophilic film, a microporous hydrophobic film or a composite film of the two;

[0042] Step 3 103, using digital inkjet technology to print the designed printing pattern on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com