Special electrolytic lead anode strip hoisting and assembling device

A special device and anode piece technology, applied in the field of hoisting machinery, to achieve the effect of reducing labor intensity and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

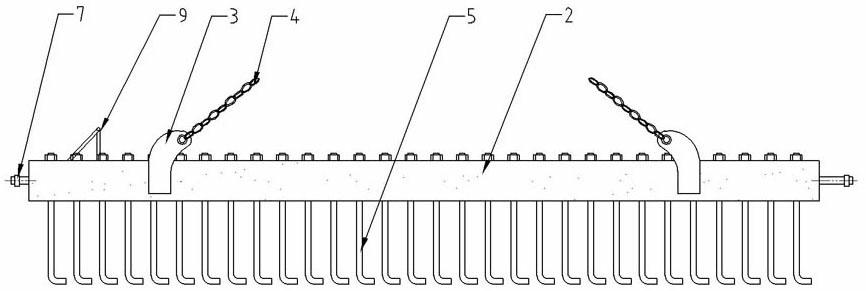

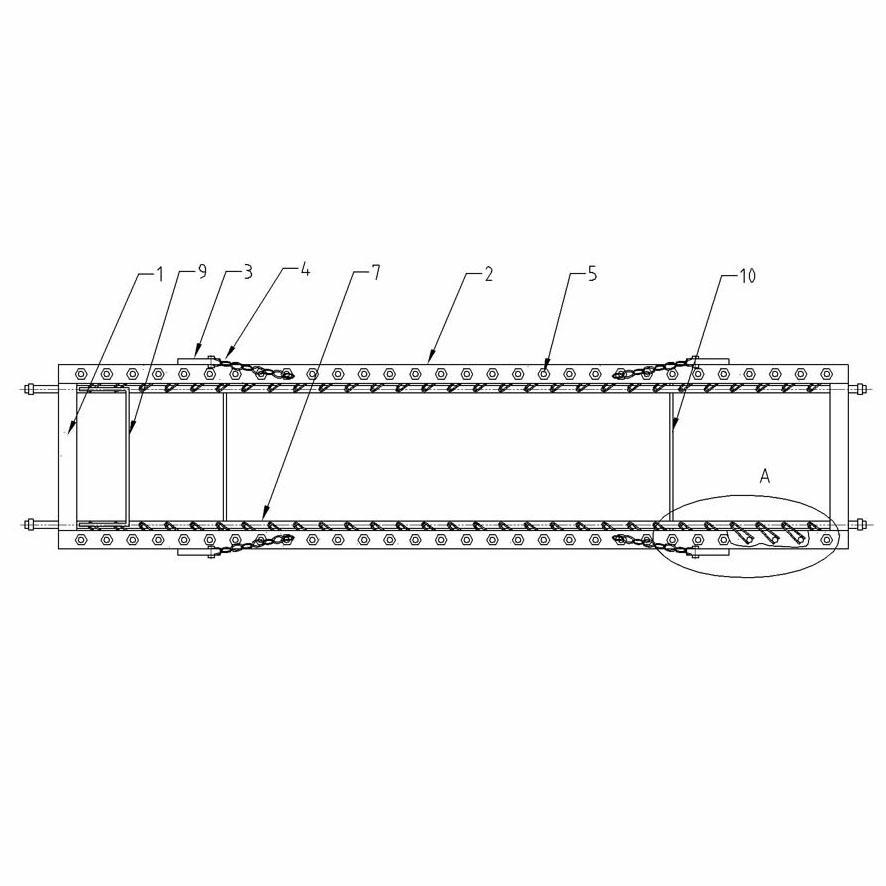

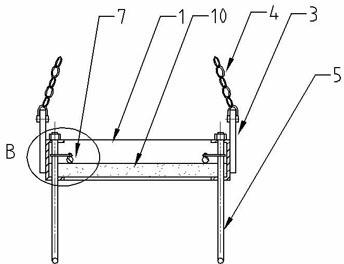

[0018] A special device for hoisting and assembling electrolytic lead anode sheets, including a rectangular frame-shaped hanger welded by two short channel steels 1 and two long channel steels 2, and the two long channel steels 2 A pair of lifting lugs 3 are welded symmetrically on the waist lengthwise, and the two pairs of lifting lugs 3 are connected to the lifting equipment through the lifting rope 4; the two legs of each long channel steel are provided with 24-36 pairs of vertically penetrating and evenly distributed Hook holes, each pair of hook holes is equipped with a round rod hook 5 whose lower end is bent into an "L" shape; The cap head is welded at the shaft part between the two legs of the channel steel with a turning handle 6 perpendicular to the axial direction of the shaft and with a long oval hole at the end; Two sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com