Emulsified base distribution station

A technology of emulsified matrix and distribution station, which is applied in the direction of explosives, etc., and can solve problems such as low production capacity, limited promotion, and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

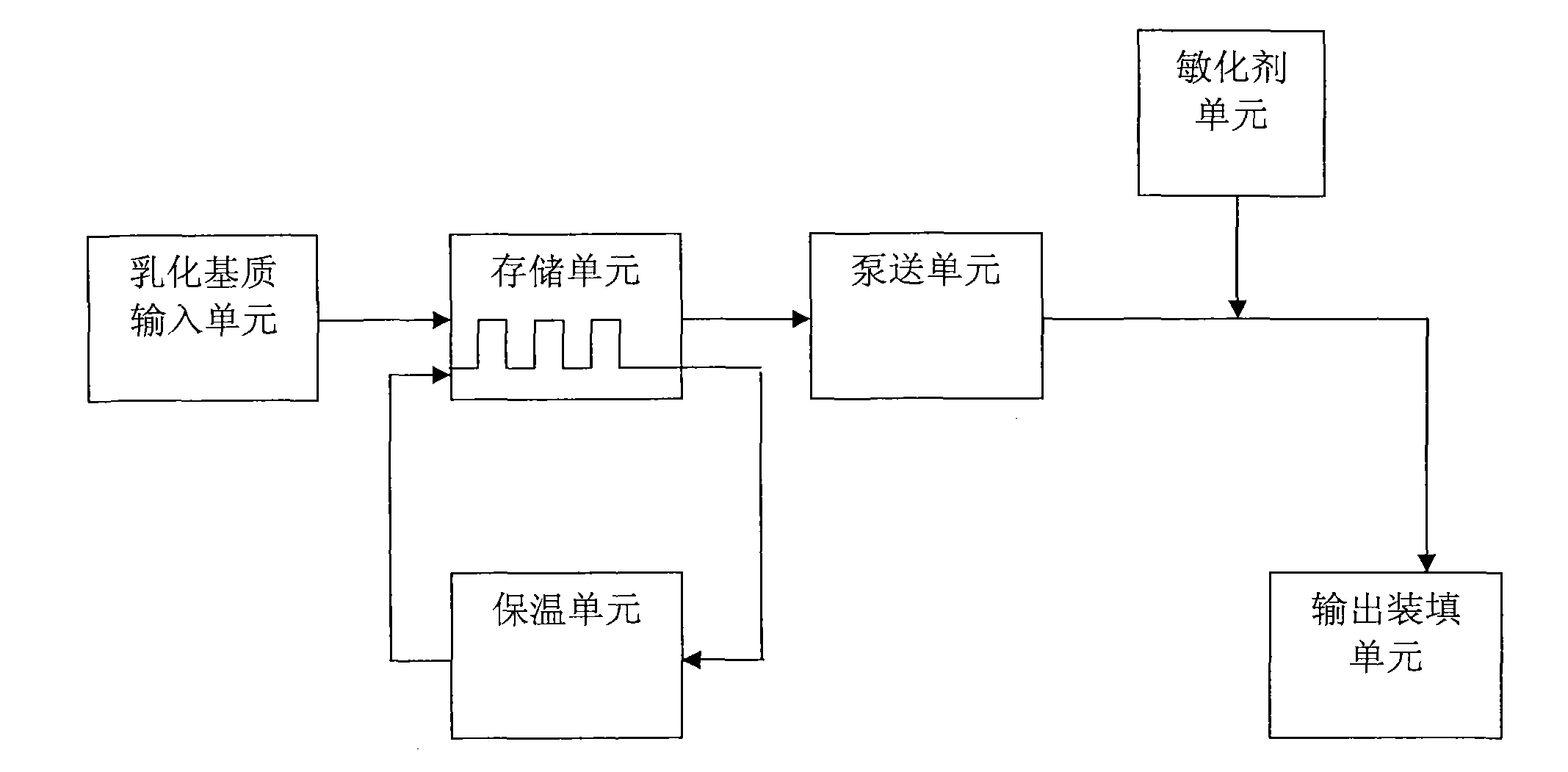

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, there are any one of the following three ways for the emulsification matrix to be sent to the distribution station by the input unit:

[0036] 1. After the input unit enters the distribution station, it is connected to the storage unit through the pump, and the emulsified matrix is pumped into the storage unit;

[0037] 2. There is a heating or insulation container on the input unit, in which the emulsification matrix is contained. After the input unit enters the distribution station, the heating or insulation container is completely unloaded, placed in the distribution station, converted into a storage unit, and then connected by pipelines to the holding unit and the pumping unit.

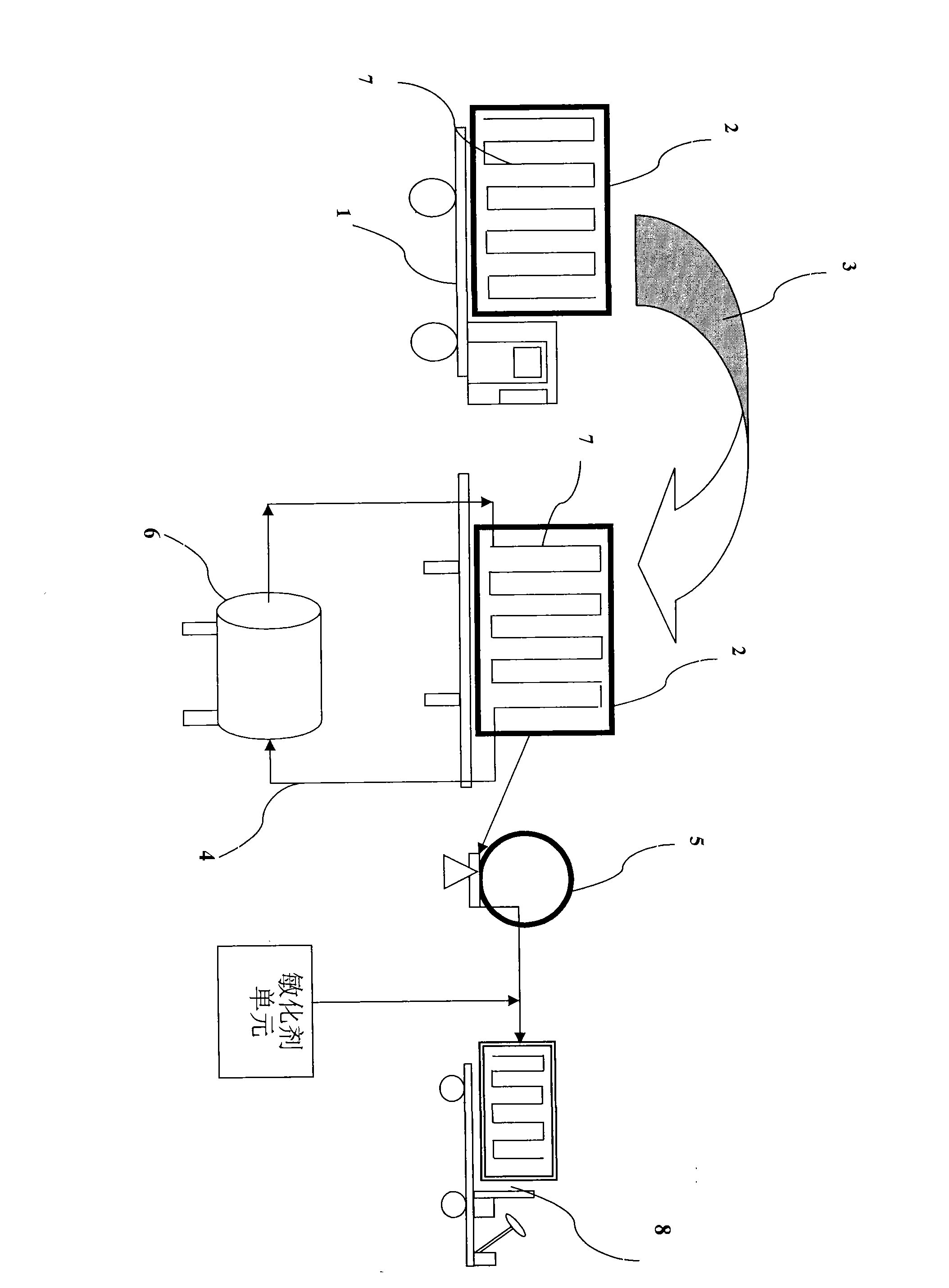

[0038] The input unit behaves as a tanker 1, see figure 2 , there is a heating / insulation container on it, that is, the tank 2, in which the emulsification matrix is contained. After the input unit enters the distribution station, the entire tank 2 is unloaded and hois...

Embodiment 2

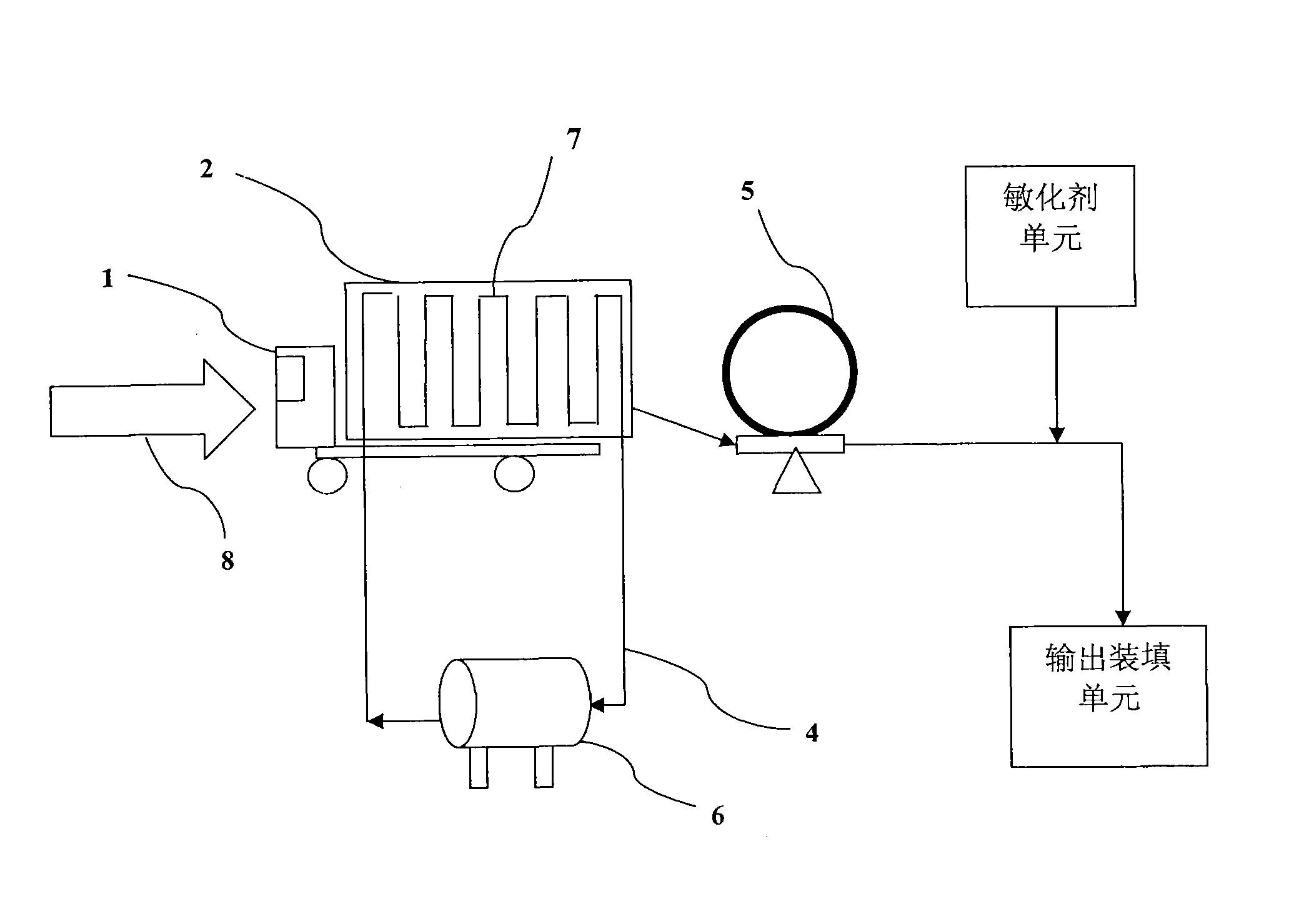

[0041] Embodiment 2, the substrate input unit is a conveying vehicle 1 with a heating or thermal insulation container, so that the emulsified substrate contained in it is maintained at a preset temperature, such as a tank truck 1, and the tank 2 on it is connected to the vehicle body. It can be separated or integrated; the storage unit includes at least one container with a thermal insulation device. The emulsification base contained in it is maintained at a preset temperature.

Embodiment 3

[0042] In the third embodiment, the pumping unit 5 is a suitable device such as a screw pump, a plunger pump or a diaphragm pump, and is powered by an air compressor, an electric motor, or a hydraulic device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com