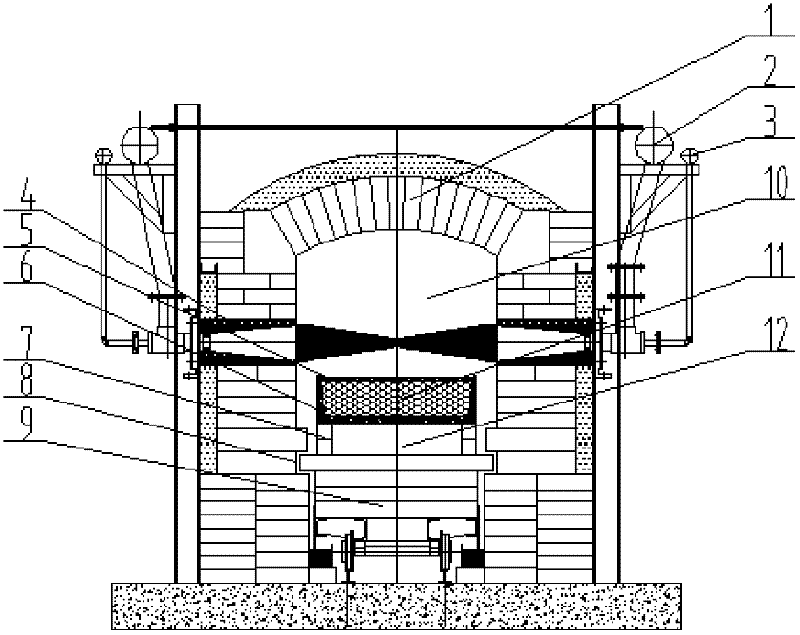

Reduction kiln equipment and method for directly reducing iron

A reduced iron and kiln technology, applied in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problem of inability to reduce and separate reduced iron products, and achieve the effect of reducing reduction time, good effect, and preventing heat from running up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Adopt the reduction kiln equipment direct reduction iron of above-mentioned direct reduction iron, carry out as follows:

[0025] (1) Preheat the kiln equipment of direct reduced iron to make its temperature reach 1110°C;

[0026] (2) The antelope stone with TFe=67.4% is made into pellets with a diameter of Φ8-16mm, mixed with the reducing agent at a mass ratio of 3:1, and the mixed material is loaded into the kiln car feed pan, and the reduction The agent is coal powder, and its chemical composition is 66.94% of fixed carbon, 21.43% of ash, 7.96% of volatile matter, 3.0% of water, and 0.67% of S in terms of mass percentage;

[0027] (3) Spread the covering agent on the top of the mixed material through the distributing machine, the tile thickness is 10-25mm, and push the kiln car into the kiln. The chemical composition of the covering agent is: fixed carbon 38.9wt%, The volatile content is 4.5wt%, the ash content is 53.60wt%, the water content is 3.0wt%, the basicity ...

Embodiment 2

[0031] Adopt the reduction kiln equipment direct reduction iron of above-mentioned direct reduction iron, carry out as follows:

[0032] (1) Kiln equipment for preheating direct reduced iron to a temperature of 1200°C;

[0033] (2) The antelope stone with TFe=40.46% is made into pellets with a diameter of Φ8~16mm, and then mixed with the reducing agent at a mass ratio of 3:1, and the mixed material is put into the material pan of the kiln car, and the reduction The agent is coal powder, and its chemical composition is 66.94% of fixed carbon, 21.43% of ash, 7.96% of volatile matter, 3.0% of water, and 0.67% of S in terms of mass percentage;

[0034] (3) Spread the covering agent on the top of the mixed material through the distributing machine, the tile thickness is 10-25mm, and push the kiln car into the kiln. The chemical composition of the covering agent is: fixed carbon 35wt%, volatile Particle 6.5wt%, Ash 53.50wt%, Moisture 5.0wt%, Alkalinity R 0.15, Particle size 0.1-3mm...

Embodiment 3

[0038] Adopt the reduction kiln equipment direct reduction iron of above-mentioned direct reduction iron, carry out as follows:

[0039] (1) Kiln equipment for preheating direct reduced iron to a temperature of 1200°C;

[0040] (2) The oolitic hematite with TFe=45.76% is made into pellets with a diameter of Φ8-16mm, and then mixed with the reducing agent at a mass ratio of 3:1, and the mixed material is put into the kiln car feed pan, so that Described reductant is pulverized coal, and its chemical composition is 66.94% by mass percentage, and ash is 21.43%, and volatile matter is 7.96%, and moisture content is 3.0%, and S is 0.67%;

[0041] (3) Spread the covering agent on the top of the mixed material through the distributing machine, the tile thickness is 10-25mm, and push the kiln car into the kiln. The chemical composition of the covering agent is: fixed carbon 38.9wt%, The volatile content is 4.5wt%, the ash content is 53.60wt%, the water content is 3.0wt%, the basicity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com