Evaporator based on heat conduction oil evaporation mechanism

A technology of heat conduction oil and evaporator, which is applied in gaseous chemical plating, metal material coating process, coating, etc. It can solve the problems of difficult heat transfer, limit evaporation efficiency, reduce the heating effect of evaporator, etc., and achieve good heating effect , Improve the evaporation effect, the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

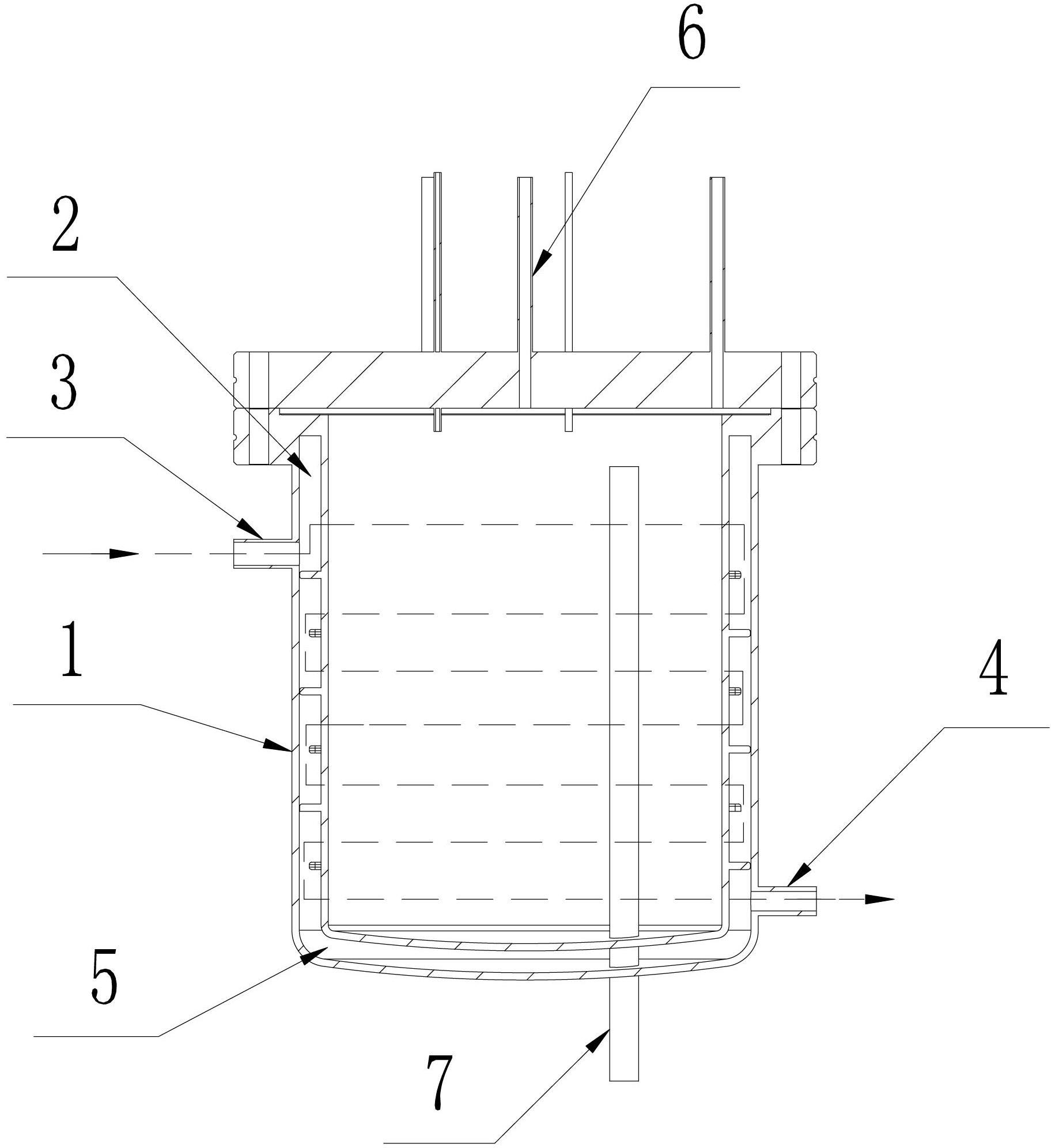

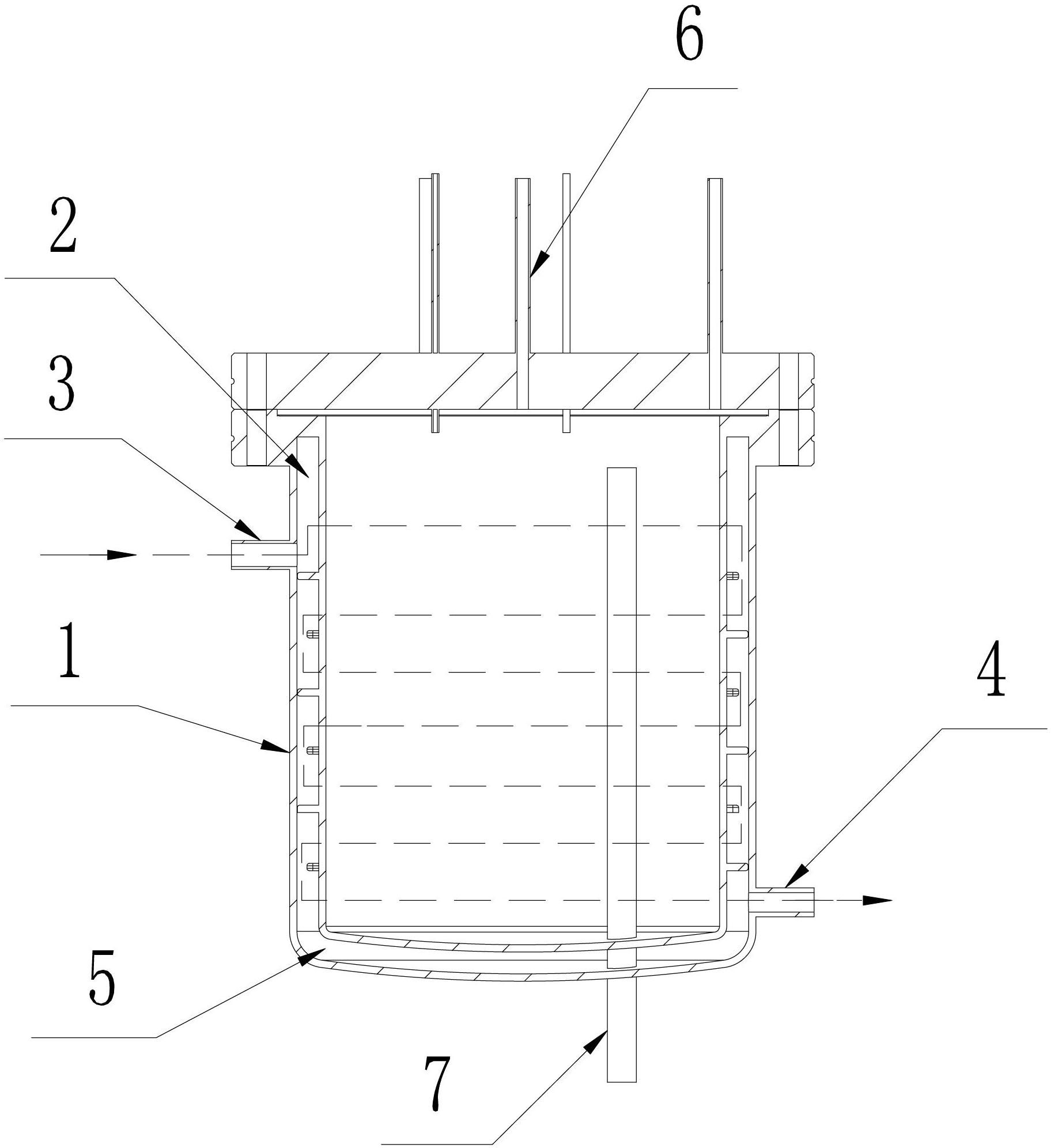

[0015] Example: Combine figure 1 As shown, the present invention provides a kind of evaporator based on heat-conducting oil evaporation mechanism, which has an evaporation container 1, the same as the conventional technology, the top of the evaporation container 1 is fixed with a liquid pipe 6 extending into the evaporation container 1, and The bottom of the evaporating container 1 is fixed with an evaporating gas discharge pipe 7 extending into the evaporating container 1 . The core technical improvement of the present invention is that an interlayer is provided inside the side wall of the evaporating container 1, and a spiral heat-conducting oil channel 2 surrounding the evaporating container 1 is provided in the interlayer, and at the same time, a The heat transfer oil inlet 3 and the heat transfer oil outlet 4 respectively connected to the two ends of the spiral heat transfer oil passage 2. and specifically as figure 1 As shown, the position of the heat transfer oil inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com