Conductive yarn and cloth structure applying same

A technology of conductive yarn and metal conductive thread, applied in yarn, textile, papermaking, textile and other directions, can solve problems such as space drying, noise, etc., achieve good expansion and contraction space, and save power and electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, please also refer to the disclosed drawings and figure numbers, and the details are as follows:

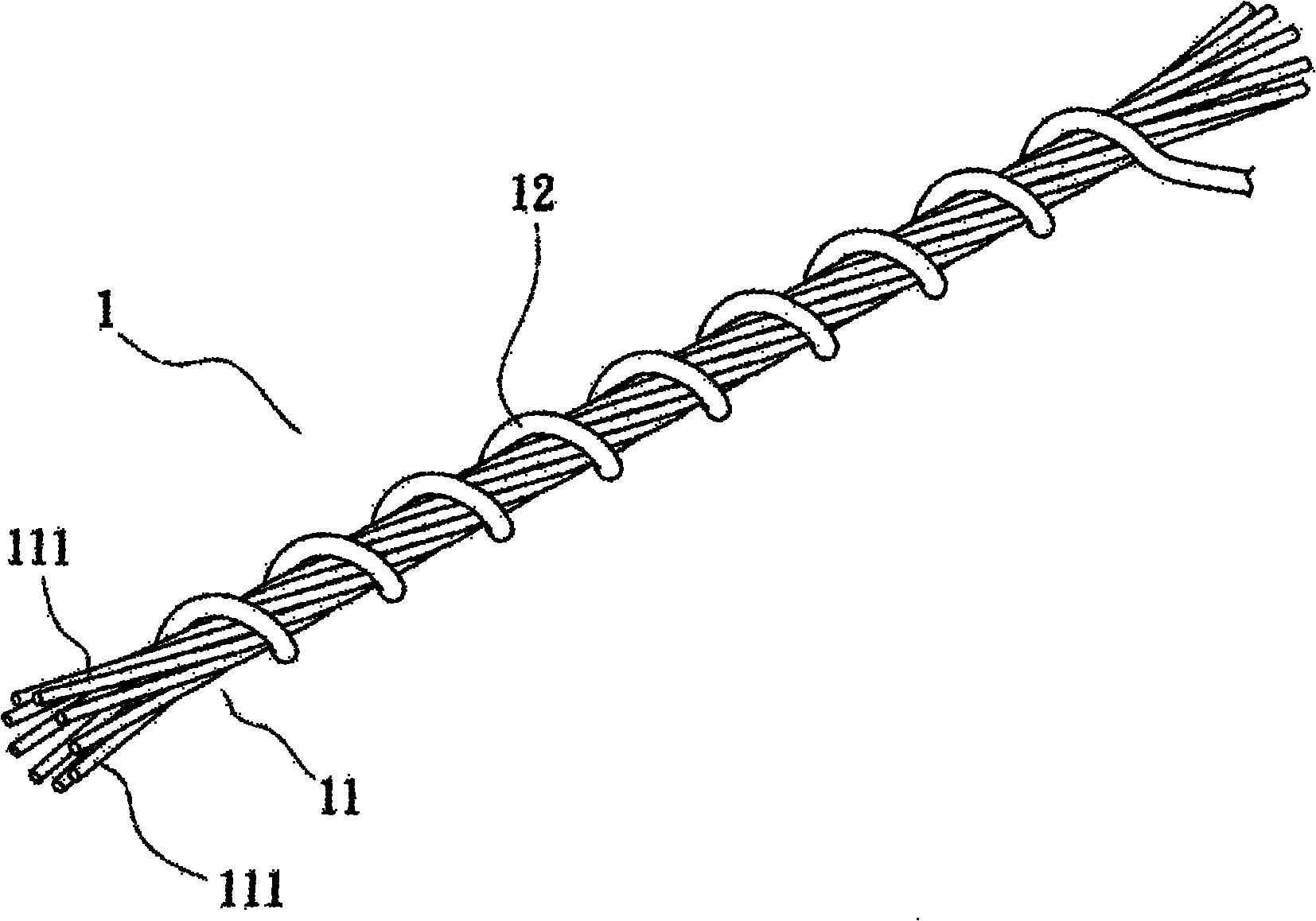

[0038] First, see figure 1 As shown, it is a schematic diagram of a conductive yarn of the present invention, and its conductive yarn 1 mainly includes:

[0039] A yarn 11 is a yarn 11 composed of multi-core fiber filaments 111;

[0040] A heating wire 12 is correspondingly wound on the outer surface of the yarn 11 in a helical manner, so that the yarn 11 has conductivity.

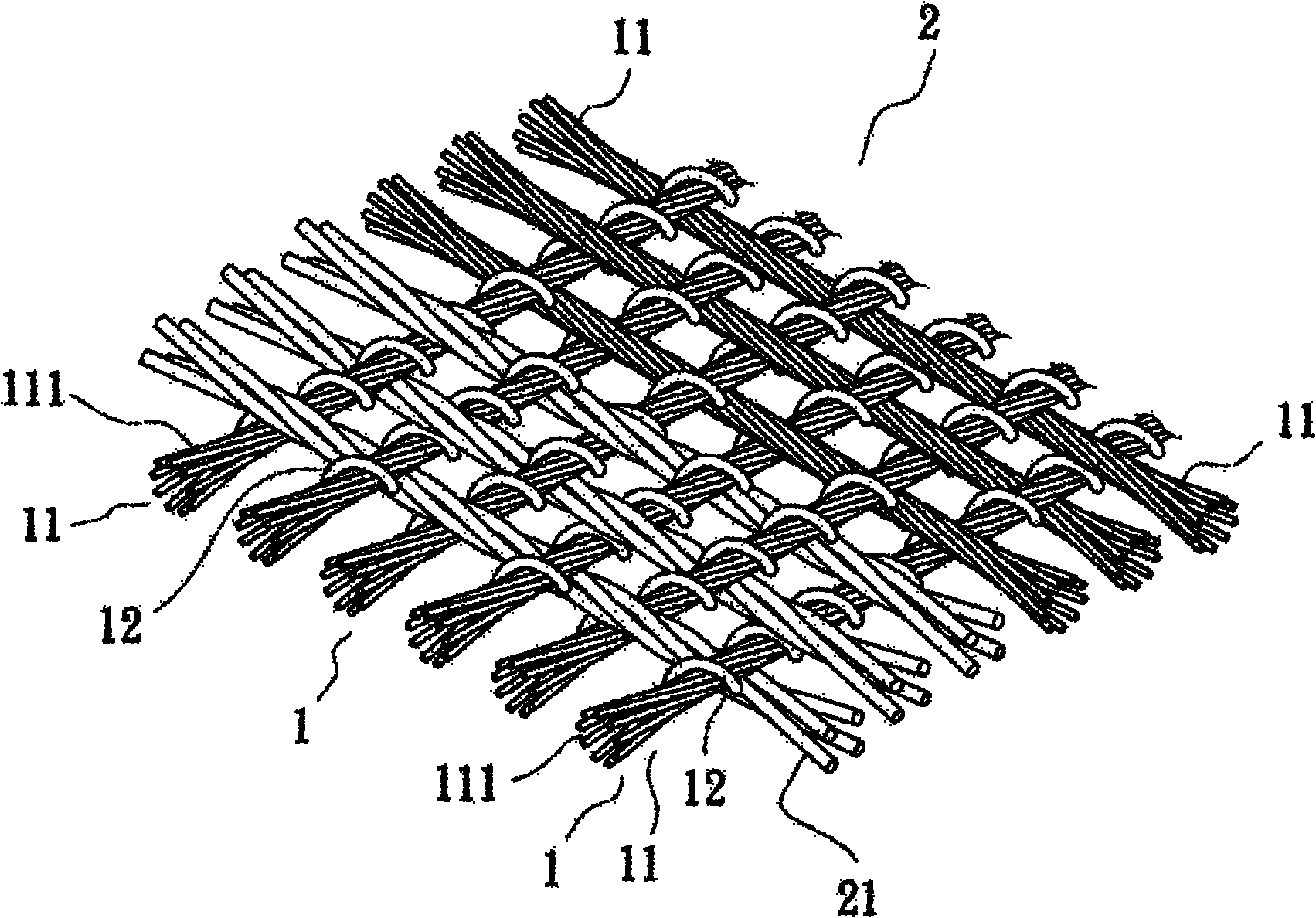

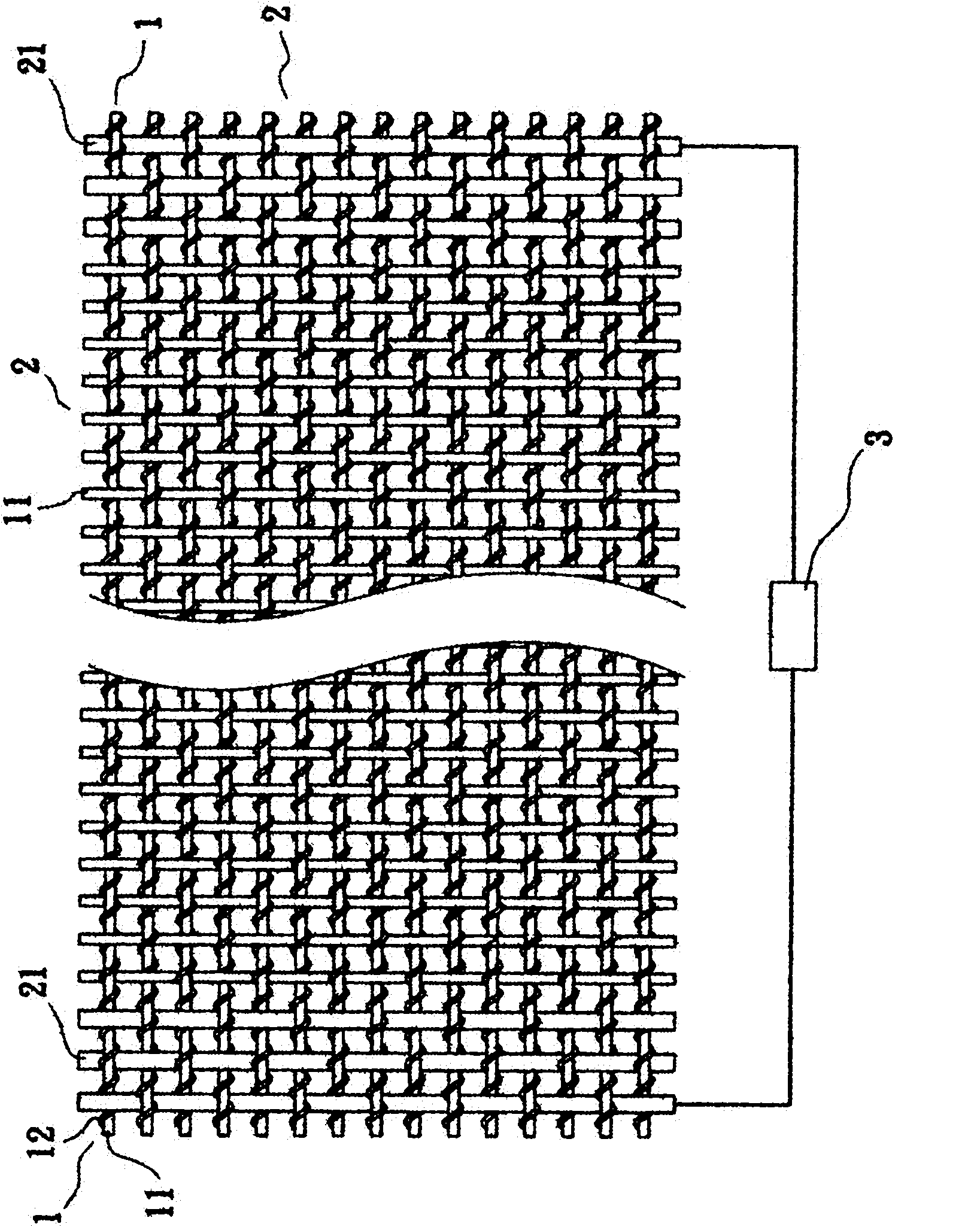

[0041] Please also refer to figure 2 , 3 As shown, it is a schematic diagram of the cloth structure using conductive yarn in the present invention, and its cloth 2 mainly includes:

[0042] More than one conductive yarn 1 as the braiding thread in the first direction;

[0043] More than one yarn 11 is a yarn 11 composed of multi-core f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com