Separating shunt suction drainage water-free sweeping vehicle

A road sweeper and car body technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of short service life of mechanical tools, narrow use range, complex mechanical structure, etc., and achieve energy saving, simple structure, and cleaning powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

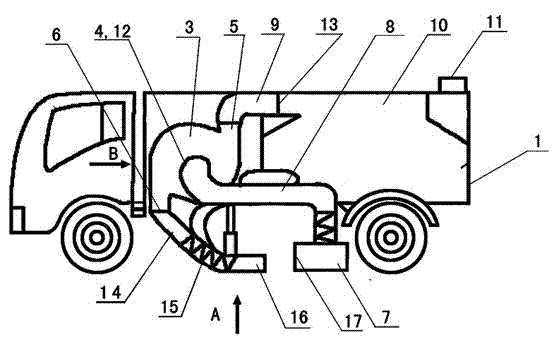

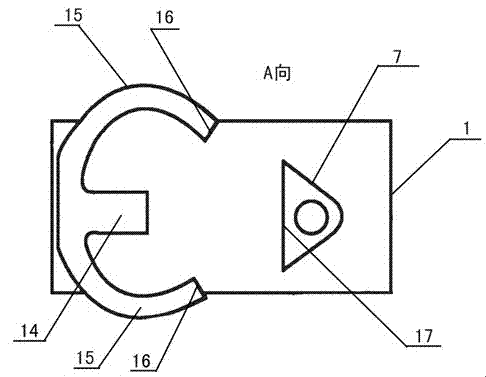

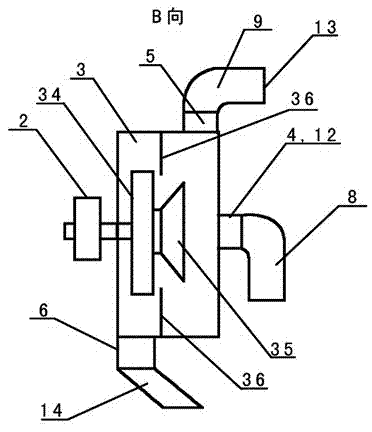

[0046] Embodiment 1, reference figure 1 , figure 2 , image 3 , Separation and diversion suction and exhaust waterless road sweeper, including car body 1, power system (pulley) 2, separation and diversion suction and exhaust fan 3, separation and diversion suction and exhaust fan impeller 34, front isolation shunt 35 of the suction and exhaust fan impeller, and inner barrier of the suction and exhaust fan Separator 36, air inlet of separation and diversion suction and exhaust fan 4, discharge port of separation and diversion suction and exhaust fan 5, exhaust port of separation and diversion suction and exhaust fan 6, garbage suction nozzle 7, garbage suction pipe 8, garbage conveying pipe 9, garbage container 10 , Garbage container air outlet 11. The garbage suction nozzle 7 is connected with the garbage suction pipe 8, the garbage suction pipe outlet 12 is connected with the air inlet 4 of the separation and diversion suction and exhaust fan, the inlet of the garbage deli...

Embodiment 2

[0050] Embodiment 2, refer to Figure 4 , Figure 5 , this example is basically the same as Example 1, and the difference is that the garbage suction pipe 8 is provided with a garbage suction branch pipe 18 connected to the garbage suction pipe downstream, and the garbage suction branch pipe 18 is located at the bottom wall of the car body, and the garbage suction The branch pipe inlet 19 points to the outer space at the bottom of the car body, and the garbage suction branch pipe inlet 19 is a bell mouth type.

[0051] During work, when the garbage cleaning nozzle blows the garbage, there will be mud and dust flying in the outer space of the bottom of the car body. Since there are garbage suction branch pipes and garbage suction branch pipe inlets, the garbage cleaning nozzle blows the mud and dust flying up from the garbage. The dust can be sucked clean by the inlet of the garbage suction branch pipe and the garbage suction branch pipe at any time, and then input into the ga...

Embodiment 3

[0053] Embodiment 3, refer to Figure 6 , Figure 7 , this example is basically the same as Example 1, the difference is that this example is provided with an auxiliary blower fan 20 --- a suction and discharge material backflow fan, the outside of the auxiliary blower fan air inlet is provided with an auxiliary blower blower inlet pipe 21, and the auxiliary blower blower inlet pipe inlet stretches into The outer space of the bottom wall of the car body; the auxiliary fan exhaust pipe 22 is arranged outside the auxiliary fan exhaust port, and the outlet of the auxiliary fan exhaust pipe 22 is communicated with the garbage container 10 . The second difference is that the outer side of the car body bottom wall in this example is provided with a dust collection cover 23, the dust collection cover outlet 24 communicates with the inlet of the auxiliary fan air inlet pipe 21, and the dust collection cover inlet 25 points to the car body bottom wall from top to bottom. outer space. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com