Novel floorboard assembling structure and connecting components thereof

A technology for connecting parts and floors, which is applied in the direction of building structure, floors, buildings, etc., can solve the problems that floors cannot be realized and connected as a whole, and achieve the effects of improving efficiency and avoiding cracking and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

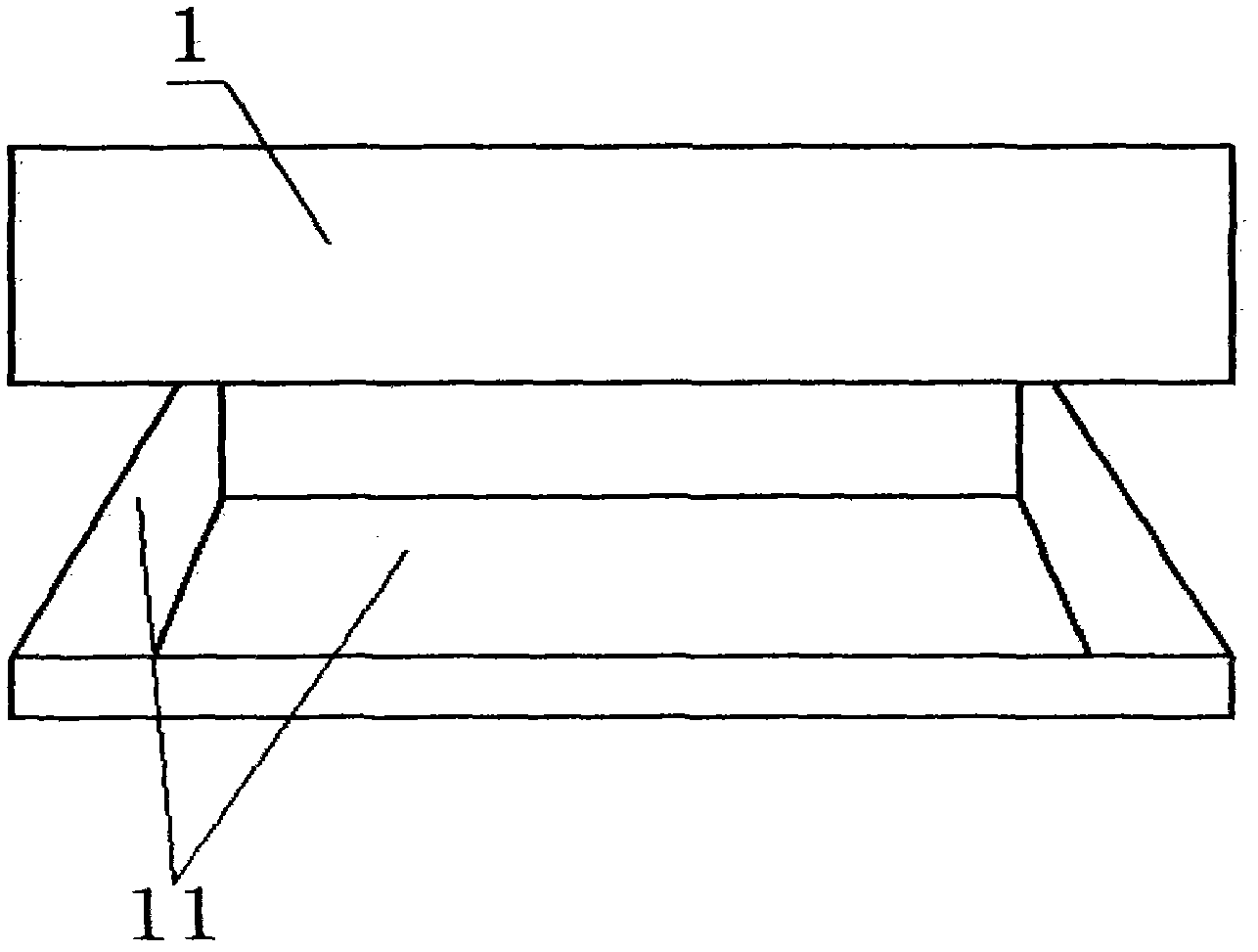

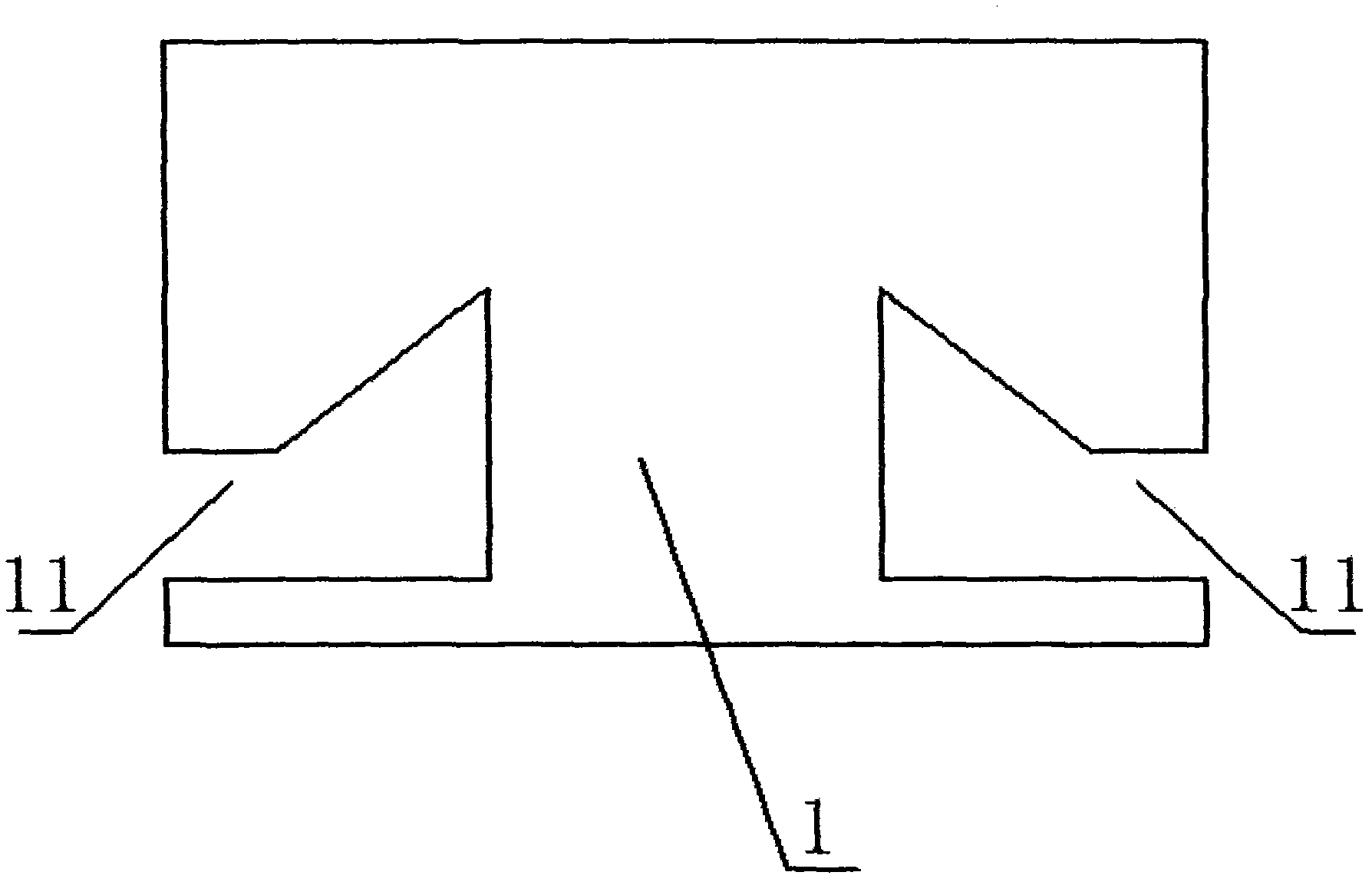

[0038] A new type of floor assembly structure and its connecting parts, including a floor body 1 and a connecting part 2, are provided with inwardly recessed slide grooves 11 on the short and long sides of the floor body 1, such as figure 1 As shown, the cross-sectional shape of the groove is as figure 2 As shown, the shape of the chute 11 is various geometric bodies capable of forming a buckle structure with the connecting component 2 , and in this embodiment, the end of the connecting component is arranged as a horizontal trapezoid at right angles.

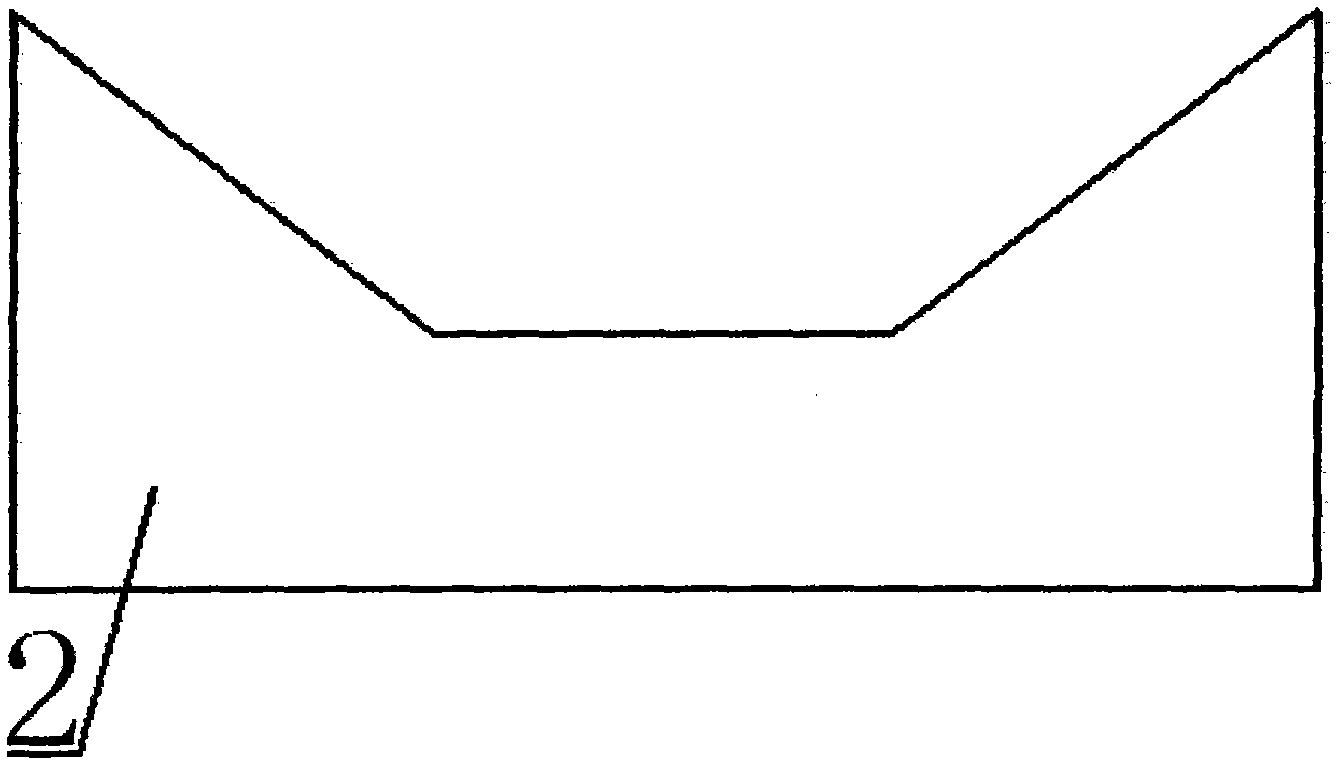

[0039] The whole of the connecting part 2 is elongated, such as image 3 , Figure 4 As shown, the opening of the connecting part is U-shaped, and the shape of both sides of the opening of the connecting part can form a state of mutual engagement with the shape of the chute 11, and the shape of both sides of the connecting part 2 is symmetrical along the central axis of its body. In this way, the connecting part 2 can realize...

Embodiment 2

[0043] In this embodiment, the opening of the connecting part is set in a V shape, such as Figure 6 As shown, the corresponding floor chute shape is as follows Figure 7 As shown, the other contents and assembling principles of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0045] In this embodiment, the end of the connecting part is set to be a horizontal isosceles trapezoid, and the opening of the connecting part is set to be U-shaped, such as Figure 8 As shown, the corresponding floor chute shape is as follows Figure 9 As shown, the other contents and assembling principles of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com