Built-in back arris precast concrete formwork-removal-free hollow wall and construction technology

A technology of prefabricated concrete and construction technology, which is applied to the preparation of formwork/formwork/work frame, walls, and building components on site. It can solve problems such as low production efficiency, pouring mold expansion, and difficulty in ensuring molding accuracy. The effect of reducing the cost, preventing the expansion of the pouring mold, and avoiding the phenomenon of mold expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

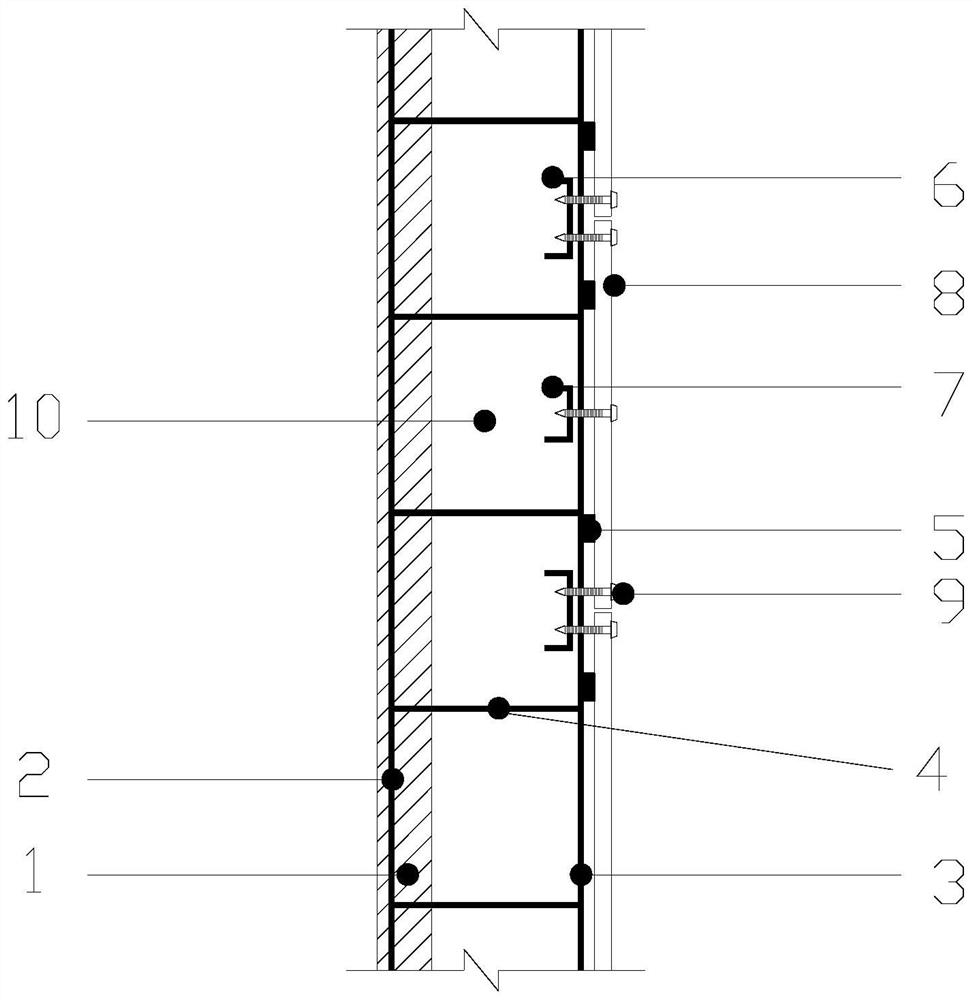

[0029] Such as figure 1 As shown, an embodiment of the present invention provides a built-in back flute precast concrete formwork-free hollow wall, including a precast concrete single-sided wall panel 1, a steel skeleton, a formwork-free built-in back flute 6 and a formwork 8, wherein the prefabricated The concrete single-sided wall panel 1 and the non-demolition formwork 8 are arranged in parallel and form a wall cavity 10 in the middle. In the prefabricated concrete single-sided wall panel 1, the formwork-free built-in back flute 6 is arranged in the wall cavity 10, and is connected with the steel skeleton and the formwork 8 without demolition.

[0030] In the embodiment of the present invention, there are multiple built-in back corrugations 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com