A corrugated welded reinforced steel plate-concrete composite shear wall

A technology of combining shear walls and corrugated steel plates, applied to building reinforcements, walls, structural elements, etc., can solve the problems of easy loosening of metal cover plates, potential safety hazards, uneven ground, etc., and achieve improved out-of-plane stiffness, Improve ductility, good restraint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

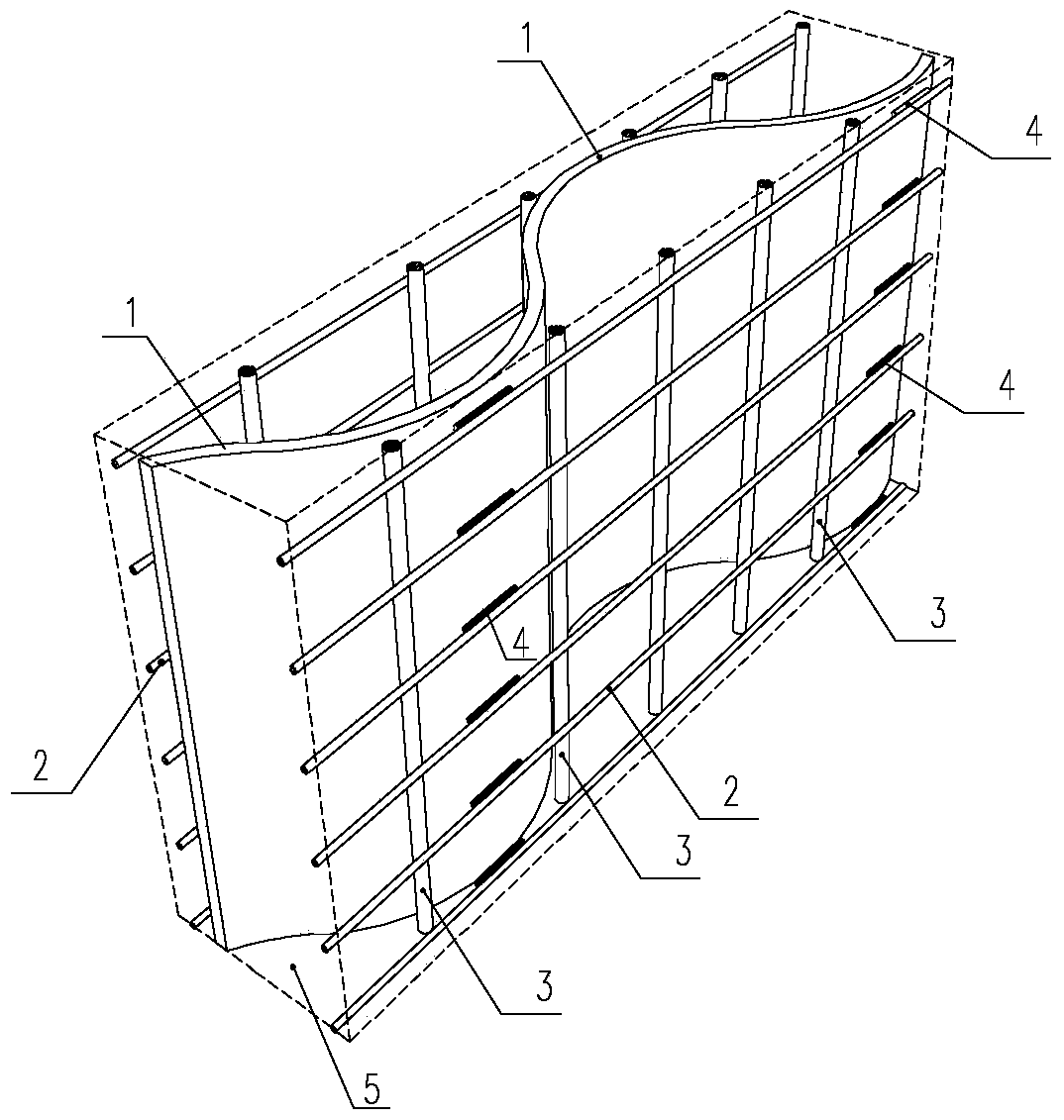

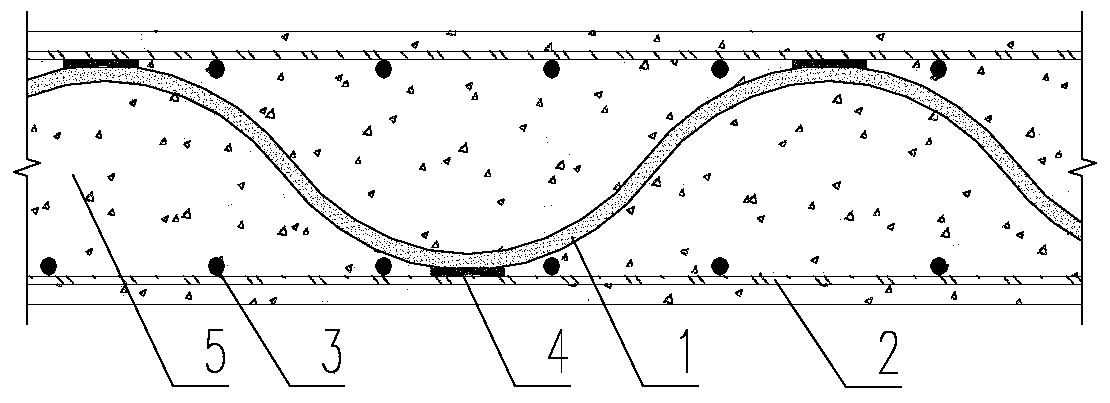

[0031] refer to figure 1 and figure 2 , this embodiment includes a concrete wall 5 and a steel bar structure built in the concrete wall 5, characterized in that: the steel bar structure is a wave-welded reinforced structure, including a corrugated steel plate 1, a horizontally distributed bar structure 2 and a vertically distributed bar structure 3, The horizontal distribution bar structure 2 is composed of several pairs of horizontally arranged steel bars, and the vertical distribution bar structure 3 is composed of several pairs of vertically arranged steel bars; the horizontal distribution bar structure 2 and the vertical distribution bar structure 3 are connected to form the concrete wall 5 The frame-shaped support structure, the corrugated steel plate 1 is located in the frame-shaped support structure, and the corrugated steel plate 1 is welded and connected with the horizontally distributed ribs or vertically distributed ribs of the frame-shaped support structure at the...

specific Embodiment 2

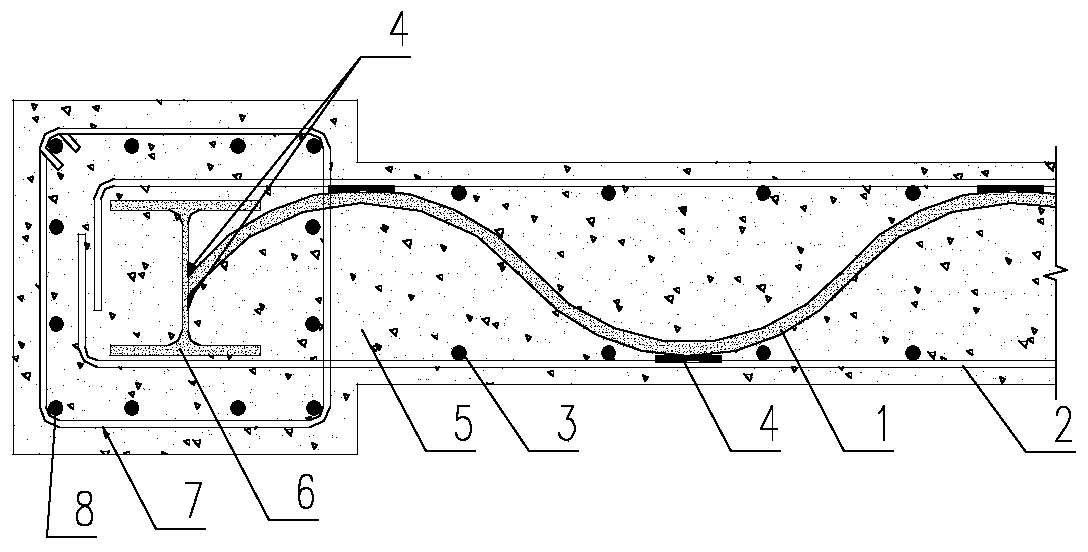

[0036] refer to image 3 , the characteristics of this embodiment 2 are: the steel plate-concrete composite shear wall includes a rectangular part and a thickened part, and the concrete wall 5 and the steel structure built in the concrete wall 5 include a rectangular part and a rectangular part. The thickened part extending from one end of the part has an "I"-shaped steel reinforcement 6 built in the thickened part, and several end longitudinal ribs 8 and several stirrups 7 are arranged in the thickened part. The corrugated steel plate 1 extends to The thickened part is fixedly connected with the "I"-shaped steel reinforcement 6, that is, a welded connection structure 4 is formed through welding connection; it consists of several end longitudinal ribs 8, several stirrup bars 7, "I"-shaped steel reinforcement 6 and corrugated steel plates 1 Form the corrugated welding reinforcement structure of the thickened part. This embodiment can effectively improve the bending resistance ...

specific Embodiment 3

[0037] refer to Figure 4 , the characteristics of this embodiment 3 are: the steel plate-concrete composite shear wall is rectangular, the concrete wall 5 and the reinforcement structure built in the concrete wall 5 are rectangular, and the end of the shear wall is provided with The semi-corrugated steel plate 9 is welded with the corrugated steel plate 1 to form a drop-shaped steel pipe column. Concrete 5 is poured inside the steel pipe column to form a steel pipe concrete column as a concealed column at the end of the shear wall.

[0038] This embodiment can provide better restraint to the internal concrete, and the transition to the corrugated steel plate 1 is also smoother. Therefore, it can be used in buildings with higher ductility requirements.

[0039] During construction, one room of corrugated steel plates between different floors can be connected by groove butt welding. The vertically distributed tendon structure 3 is inserted and bound from top to bottom. The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com