Ultra-viscous crude oil injection-production integrated technique tubular pile

A process pipe string and super-heavy oil technology, applied in the field of super-heavy oil injection-production integrated process pipe string, can solve the problems of high cost of high-vacuum heat insulation pipe, high production cost of oil production, high labor intensity of workers, etc. The effect of oil production cost, avoiding cold injury and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

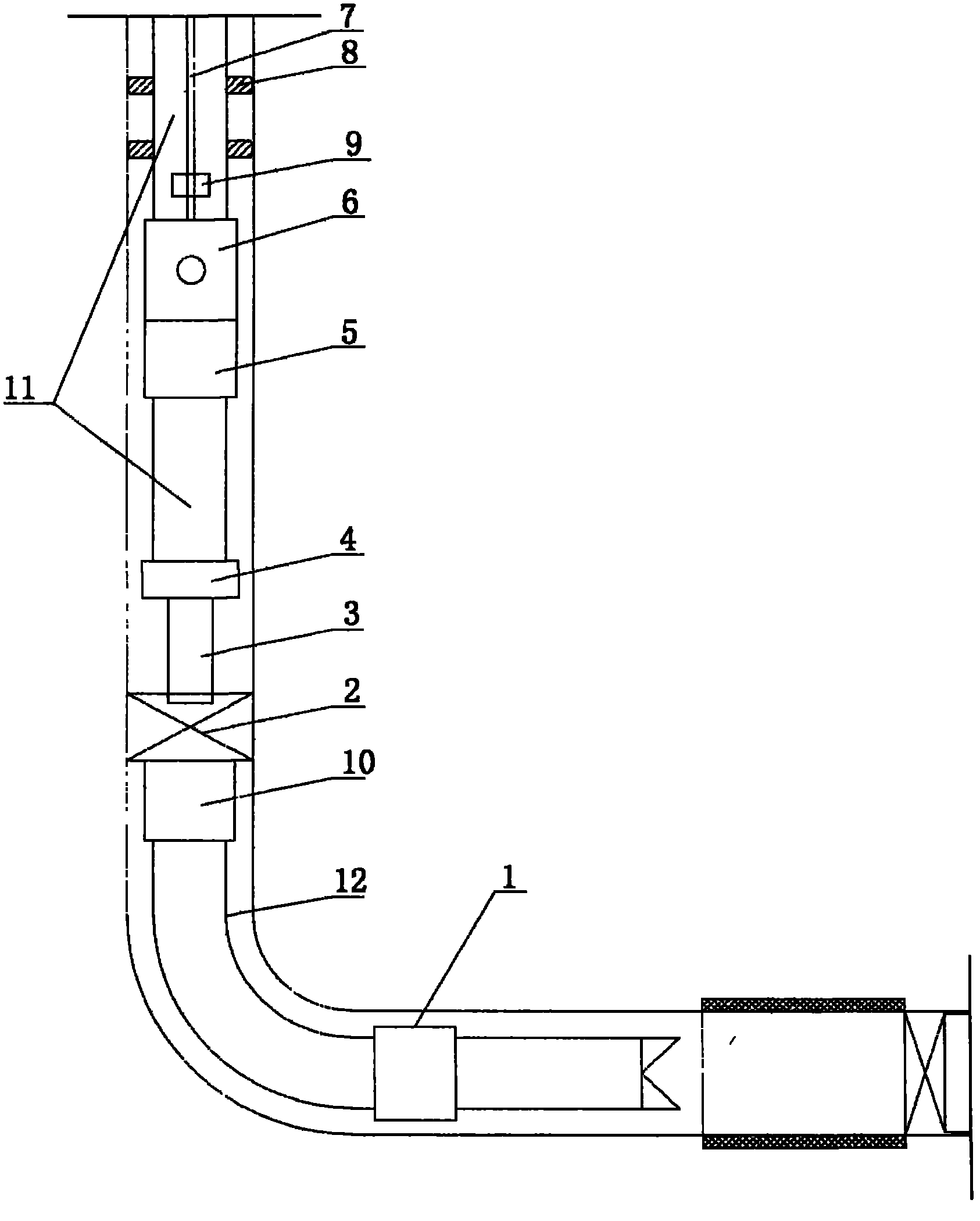

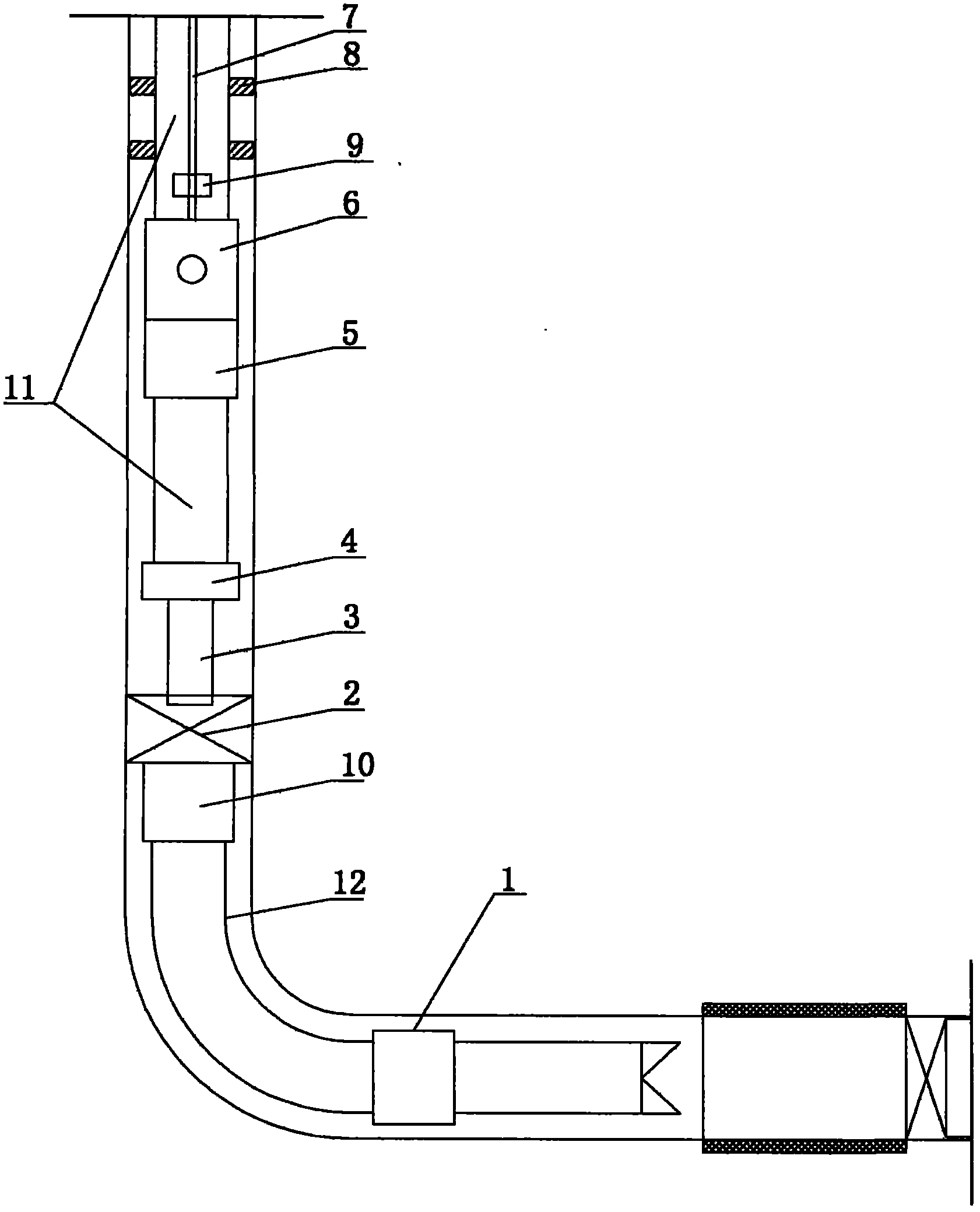

[0017] Ultra-heavy oil injection-production integrated process string, such as figure 1 As shown, it includes the tubing string set in the vertical well section and the vacuum insulation pipe string set in the horizontal well section.

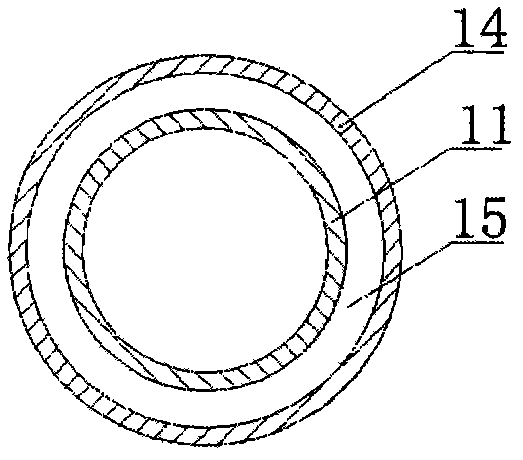

[0018] In the tubing string, the bottom end of the tubing 11 is in sealing connection with the top of the anti-backflow check valve 4 of the heavy oil well, and the bottom end of the heavy oil well anti-backflow check valve 4 is docked with the repetitive righting intubation tube 3 . Such as figure 2 As shown, there is a nitrogen insulation layer 15 between the outer wall of the oil pipe 11 and the inner wall of the oil well casing 14 . On the tubing 11, several ultra-heavy oil downhole regulators 8, ultra-heavy oil rod injectors 6, and high-temperature resistant downhole compensators 5 are installed from top to bottom. The lower end of the super-heavy oil hollow heating body 7 is connected with the high-pressure internal circulation water m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com