Differential connection structure of laser guiding arm

A technology of differential connection and light guide arm, which is applied to the connection of rods, connecting components, mechanical equipment, etc., can solve the problems that cannot meet the working requirements of the laser light guide arm, cannot guarantee the stable and reliable operation of the laser light guide arm, and achieve Small radial runout, strong connection rigidity, and the effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

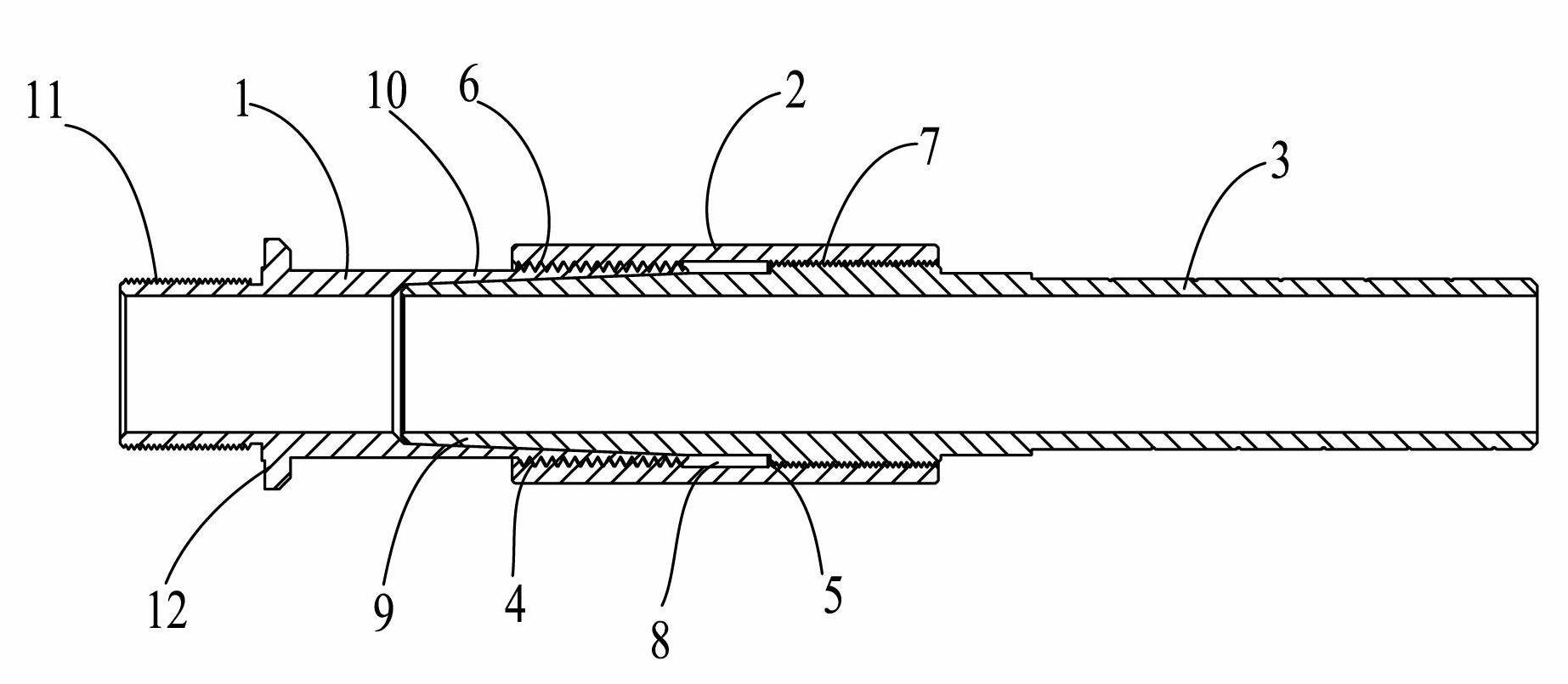

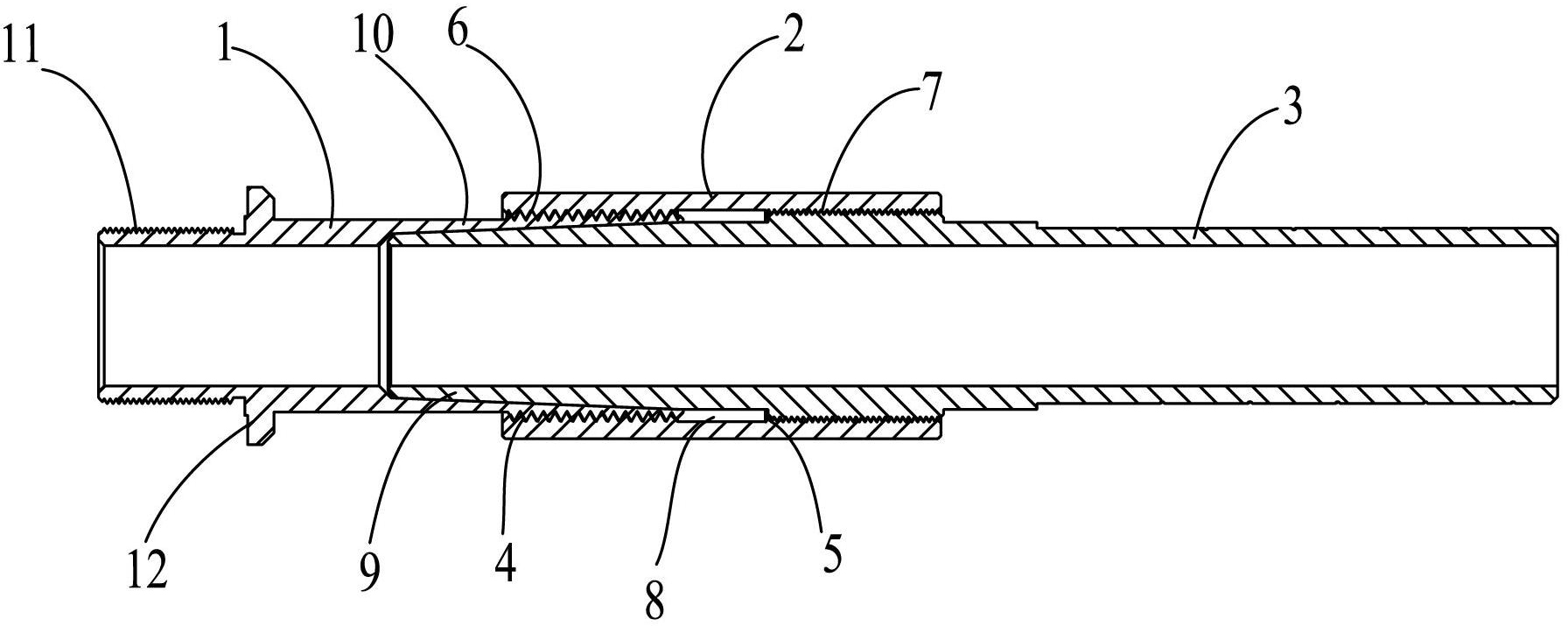

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

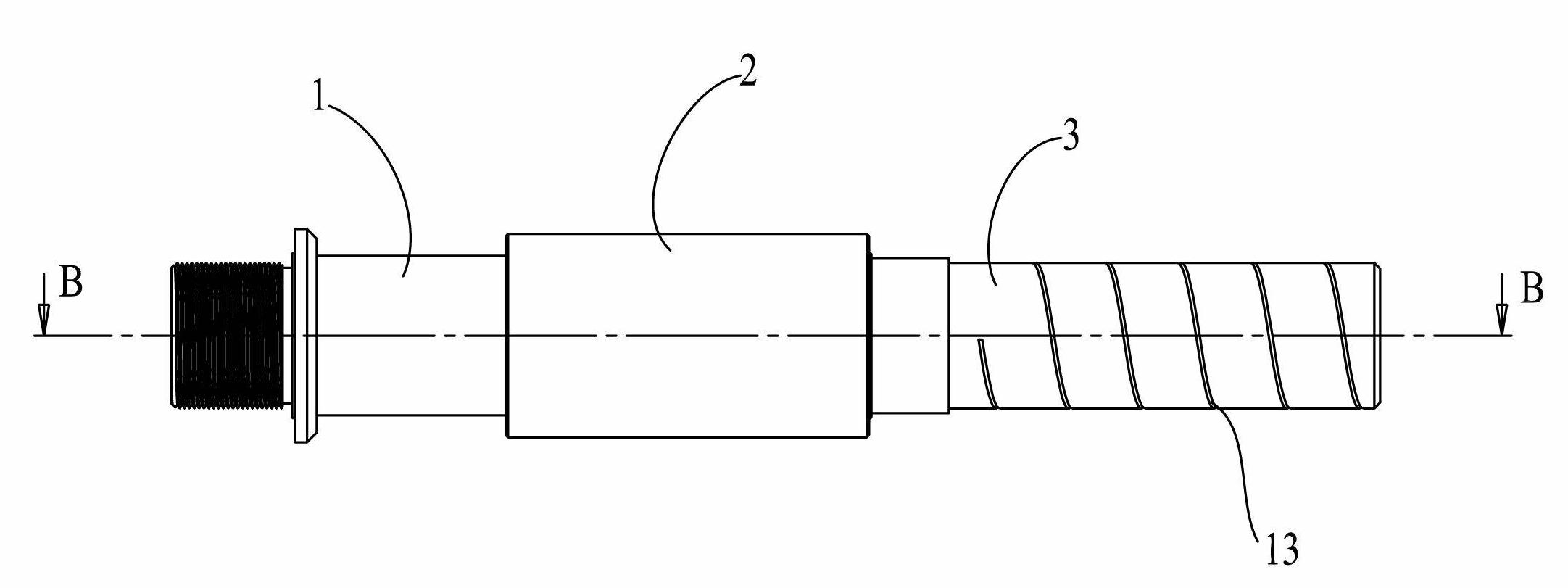

[0012] Such as Figure 1~Figure 2 As shown: the present invention includes a reducing joint 1, a differential nut 2, a light guide extension tube 3, a first fastening thread 4, a second fastening thread 5, a third fastening thread 6, a fourth fastening thread 7, Nut positioning step 8, connecting male taper end 9, connecting female taper end 10, fifth fastening thread 11, joint positioning step 12 and light pipe connecting glue groove 13.

[0013] Such as figure 1 and figure 2 As shown: the differential connection structure of the present invention includes a variable diameter joint 1 and a light guide extension tube 3 correspondingly matched with the variable diameter joint 1; one end of the variable diameter joint 1 forms a connecting female taper end 10, and the other The outer wall at one end is provided with a fifth fastening thread 11, and the variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com