Chassis manufacturing process

A manufacturing process and chassis technology, which is applied in the field of chassis manufacturing process, can solve problems such as inability to guarantee product quality, product function, and singleness of production and manufacturing, and achieve high production efficiency and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention will be further described below in conjunction with the accompanying drawings.

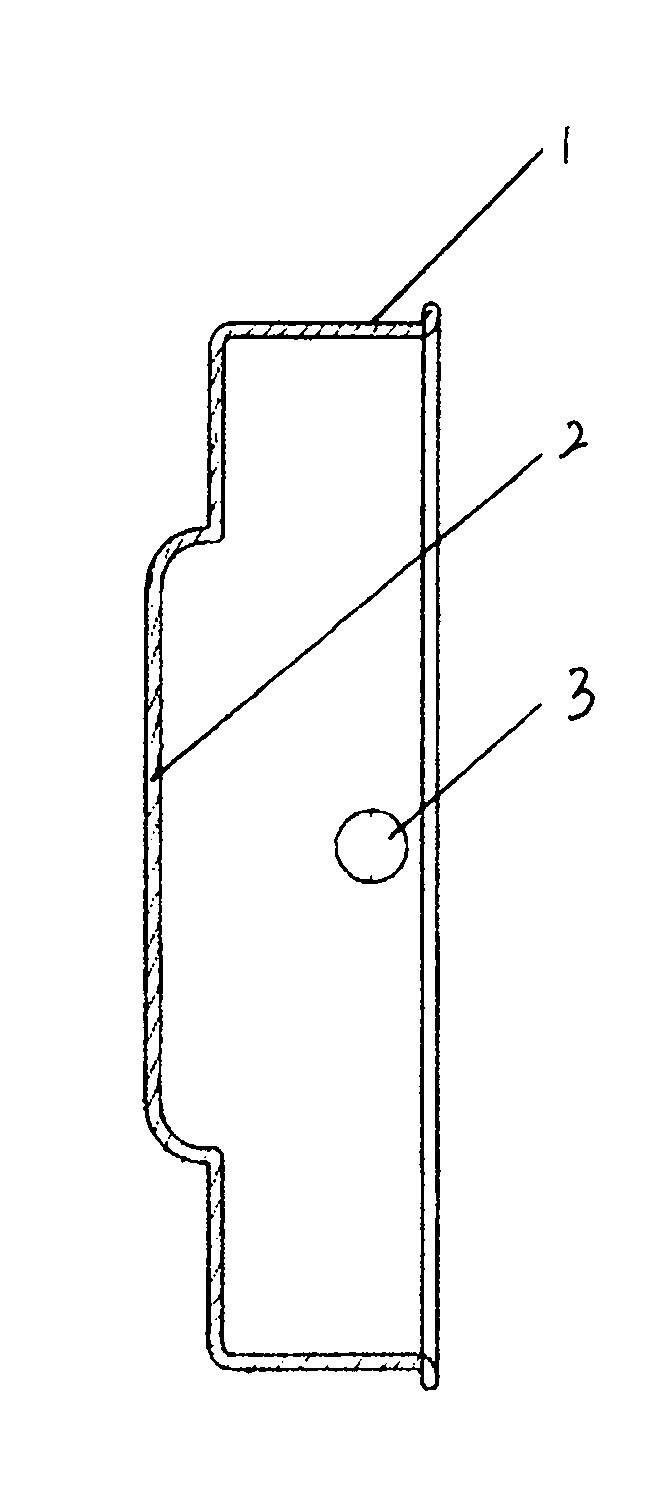

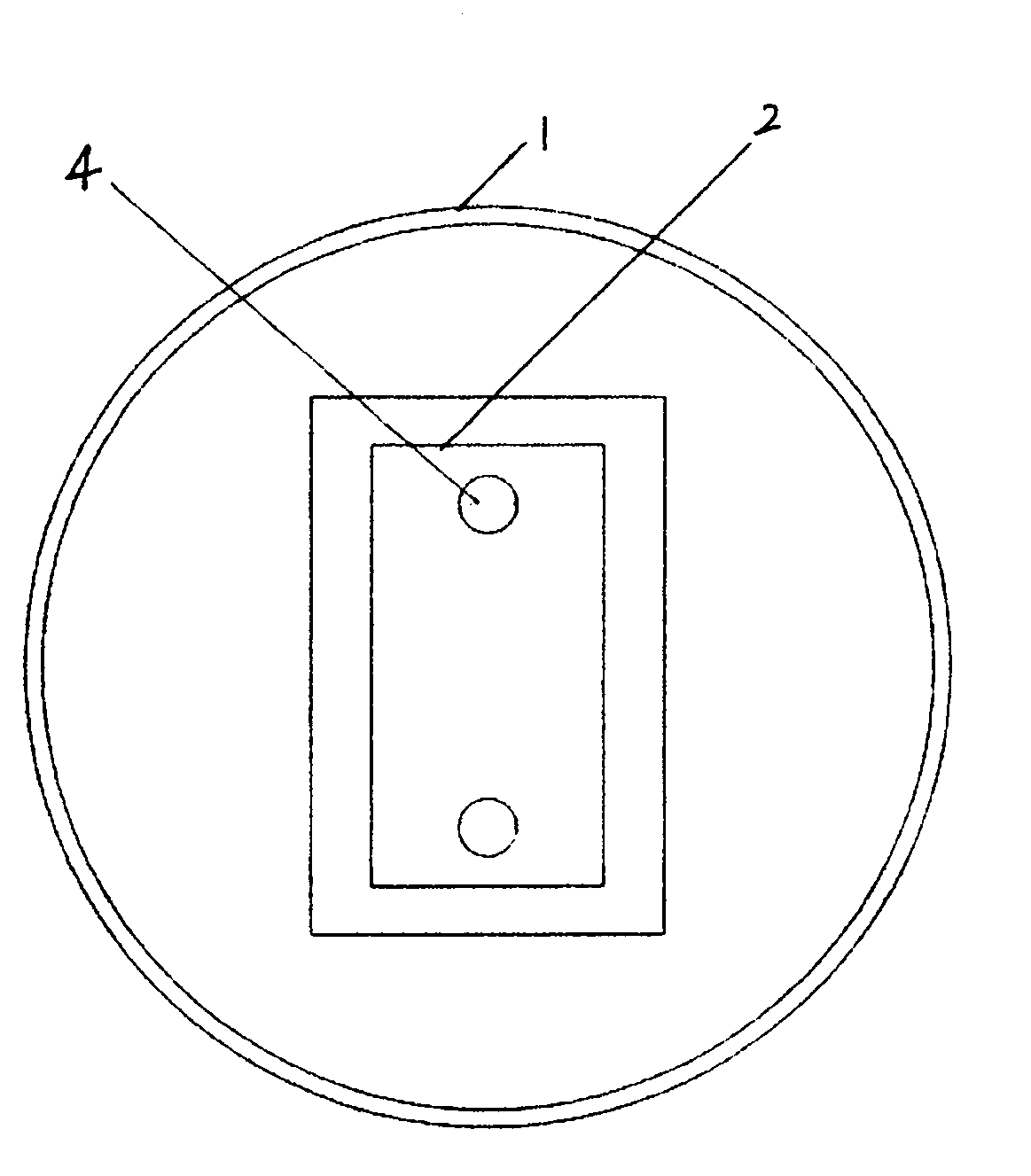

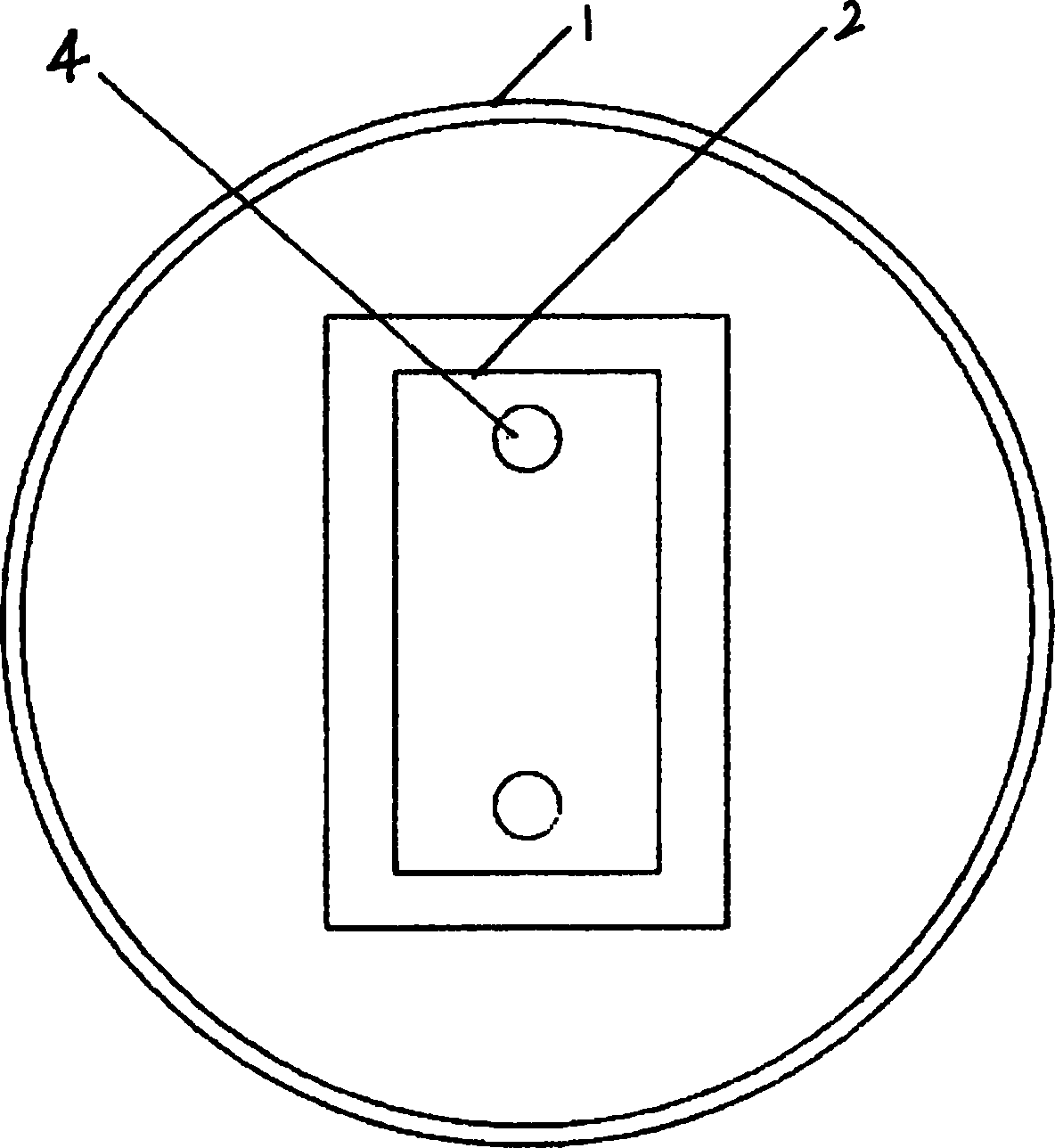

[0010] In the view, take the chassis as an example: choose 0.5mm ordinary carbon steel plate and stamp it with a special mold on the punching machine to form chassis type 1 - remove stamping flashes and burrs - punch out a rectangular convex drum in the middle of chassis 1 - in the center of the chassis Drill crank holes at both ends of the line 3-Drill two symmetrical fixing holes on the long center line of the rectangular convex drum 4-Clear the sharp corners, burrs, and metal foam left by the chassis 1 processing and soak to remove oil, rust, and phosphating-Surface Plastic spray - high temperature curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com