Energy-saving variable-frequency speed control system for hoists

A frequency conversion speed regulation and control system technology, applied in elevators, transportation and packaging, etc., can solve the problems of complex control circuits and high damage rates, and achieve the effects of reducing slip, improving power factor, and powerful compatible functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

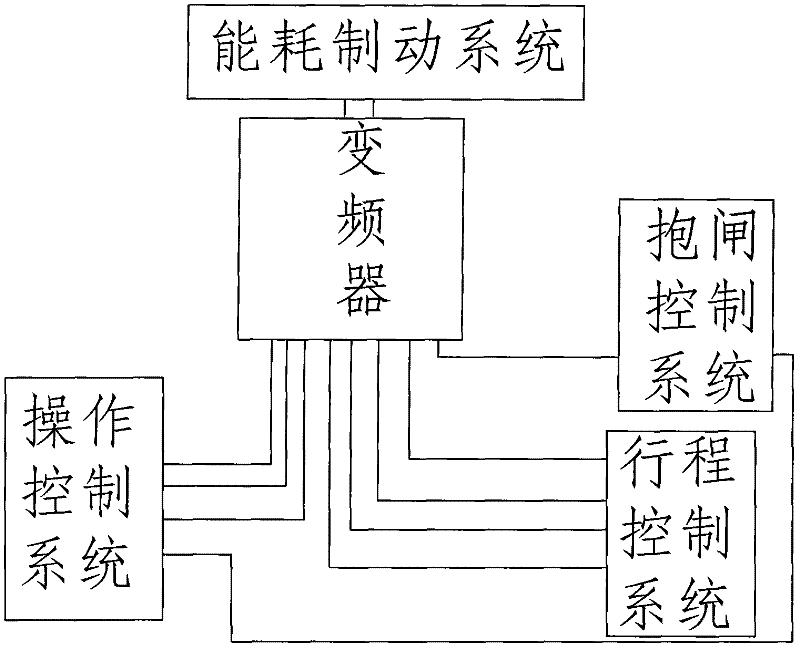

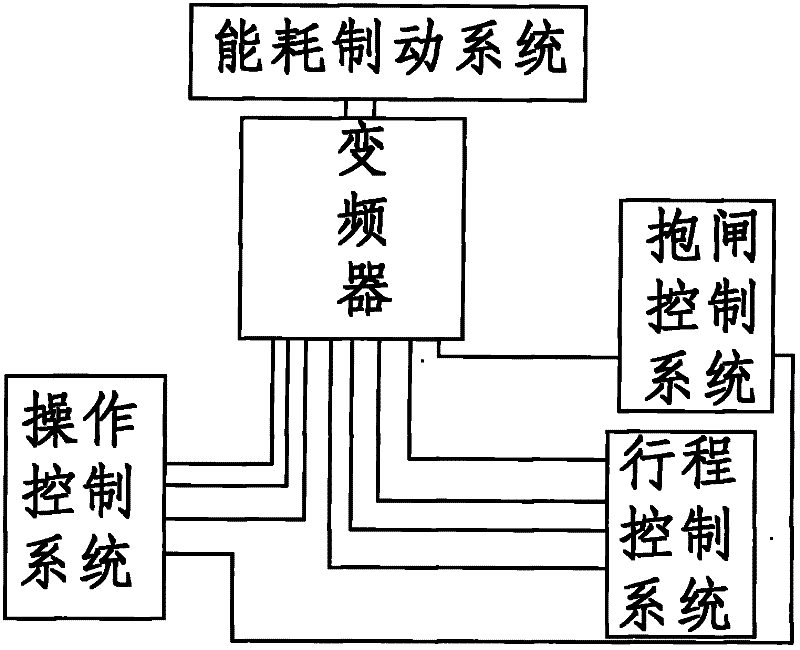

[0012] Such as figure 1 The hoist energy-saving frequency conversion speed regulation control system shown in the hoist mainly includes:

[0013] The frequency converter mainly realizes frequency conversion and speed regulation for the lifting of the hoist; the stroke control system mainly performs precise stroke control on the speed change, parking and braking of the hoist; the operation control system mainly completes the hoisting, starting and lowering of the hoist. Operation control such as start-up, fault reset and emergency braking; energy consumption braking and brake control system, mainly to realize the stop control of the hoist.

[0014] Wherein, the frequency converter mainly includes the following three kinds of frequency conversion speed regulation: constant acceleration frequency conversion speed regulation start, constant deceleration frequency conversion speed regulation stop and stroke frequency conversion speed regulation operation.

[0015] Among them, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com