Expansion compression type packer

A compression packer and packer technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling and production, etc., can solve the problems of difficult unpacking, high cost of promotion and application, and reduced work efficiency, etc. , to achieve the effect of low cost, improved safety and reliability, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

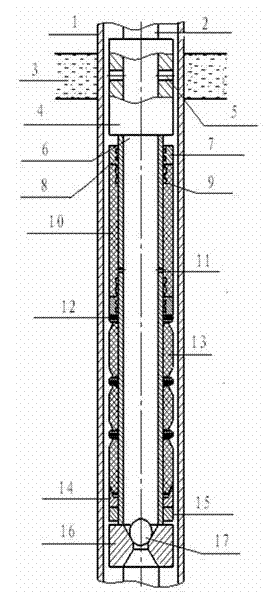

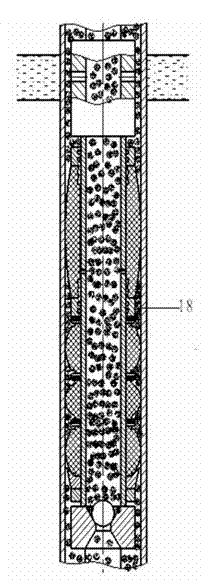

[0017] The working principle of expansion-compression packer is:

[0018] During fracturing construction, the pressure difference formed by the liquid flow under the action of the orifice of the sliding sleeve restrictor is used to set the packer. After setting, for the packer, the radial pressure difference it bears , the maximum is the pressure difference formed by the sliding sleeve restrictor, which is 2-5 MPa, and its size is related to the diameter and flow rate of the orifice 5 of the sliding sleeve restrictor; while the pressure difference between the upper and lower sides of the packer is It is the construction pressure difference between the oil layers 3, and the pressure difference must reach 70MPa at most. The pressure difference packer is under this pressure difference and the temperature in the well reaches 120°C, and it is ruptured by pressure.

[0019] The compression packer seals the casing after compressing and deforming the rubber tube to achieve the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com