Power-driven device of concrete pumping equipment and concrete pumping equipment

A concrete pump, power-driven technology, applied in the direction of fluid pressure actuation device, mechanical equipment, pump, etc., can solve problems such as the inability to meet high-pressure and large-displacement concrete pumping equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

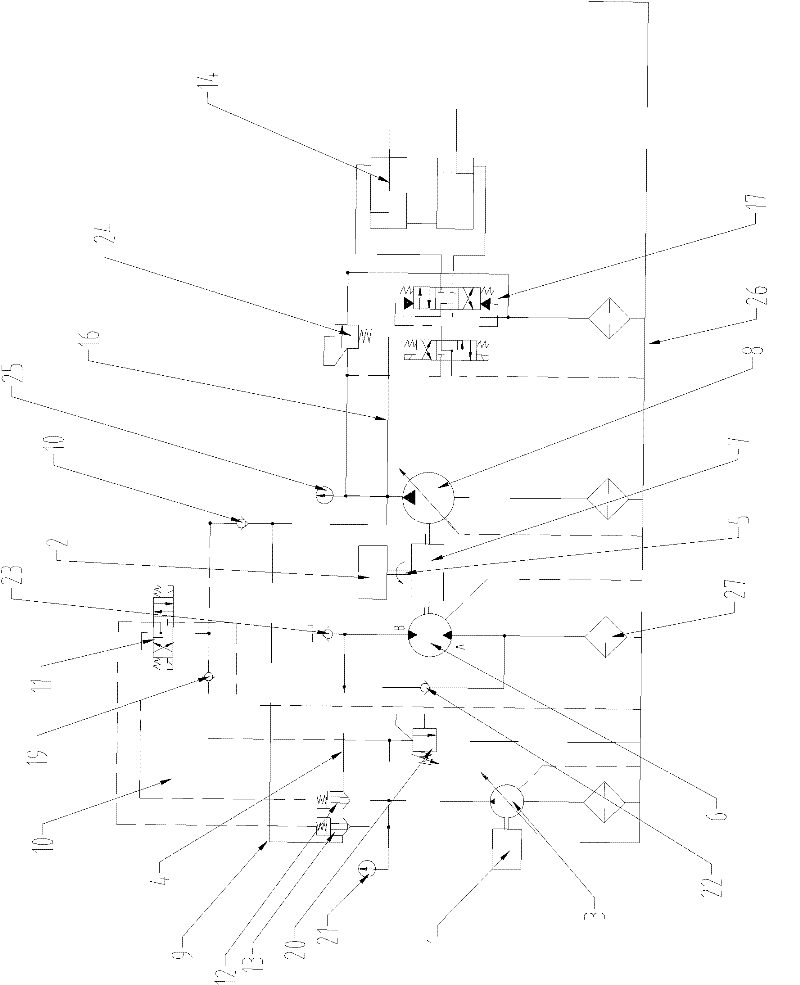

[0031] Such as image 3 As shown, according to an embodiment of the present invention, the hydraulic control element includes a first cartridge valve 12 and a second cartridge valve 13, and the two working oil ports of the first cartridge valve 12 are respectively connected to the The oil outlet of the first hydraulic pump 3 is hydraulically connected to the oil inlet of the hydraulic motor 6, and the two working oil ports of the second cartridge valve 13 are respectively connected to the oil outlet of the first hydraulic pump 3 and the oil inlet of the hydraulic motor 6. The hydraulic drive line 16 is hydraulically connected. In this way, by controlling the opening and closing of the first cartridge valve 12 and the second cartridge valve 13, the on-off of the first hydraulic pipeline 4 and the second hydraulic pipeline 9 can be conveniently controlled, thereby selectively realizing the first The first power output route or the third power output route. This control method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com