Ultrafiltration flow rate timed automatic mechanical flushing valve device

An automatic machine, flushing valve technology, applied in the valve device, valve operation/release device, ultrafiltration and other directions, can solve the problems of trouble and trouble, increase the use cost of electric shock hazard, can not meet the market diversification and other problems, achieve low cost, Guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

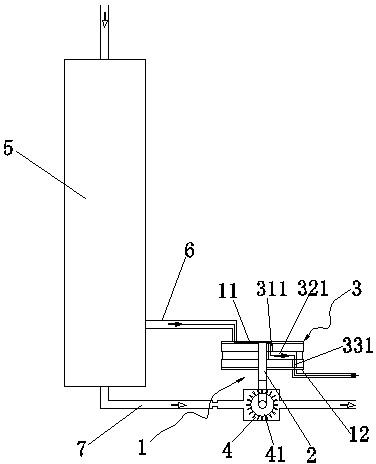

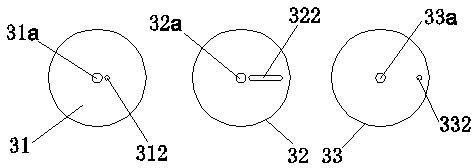

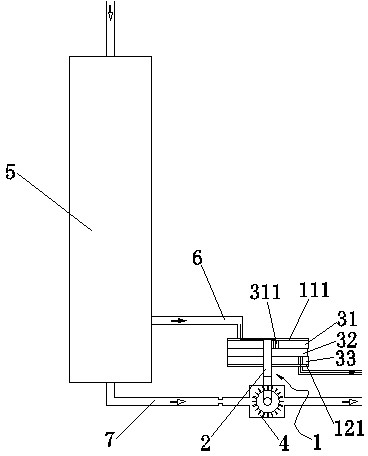

[0019] Figures 1 to 4 Shown is the structural representation of the present invention.

[0020] The reference signs are: mechanical flushing valve 1, valve upper cover 11, water inlet chamber 111, valve lower cover 12, water outlet chamber 121, valve stem 2, mechanical flushing valve diaphragm group 3, upper diaphragm 31, upper assembly Hole 31a, upper flushing water guide hole 311, upper axial through hole 312, middle diaphragm 32, middle assembly hole 32a, middle connecting channel 321, radial slot 322, lower diaphragm 33, lower assembly hole 33a, lower flushing Water guiding hole 331 , lower axial through hole 332 , driving device 4 , impeller 41 , ultrafiltration membrane 5 , flushing water pipeline 6 , and purified water outlet pipeline 7 .

[0021] like Figure 1 to Figure 4 As shown, an ultrafiltration flow timing automatic mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com