A low-concentration organic sewage treatment system

A low-concentration technology for organic wastewater treatment, applied in the field of water treatment, can solve problems such as high operating costs, difficult cleaning, and difficult use of sewage treatment devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

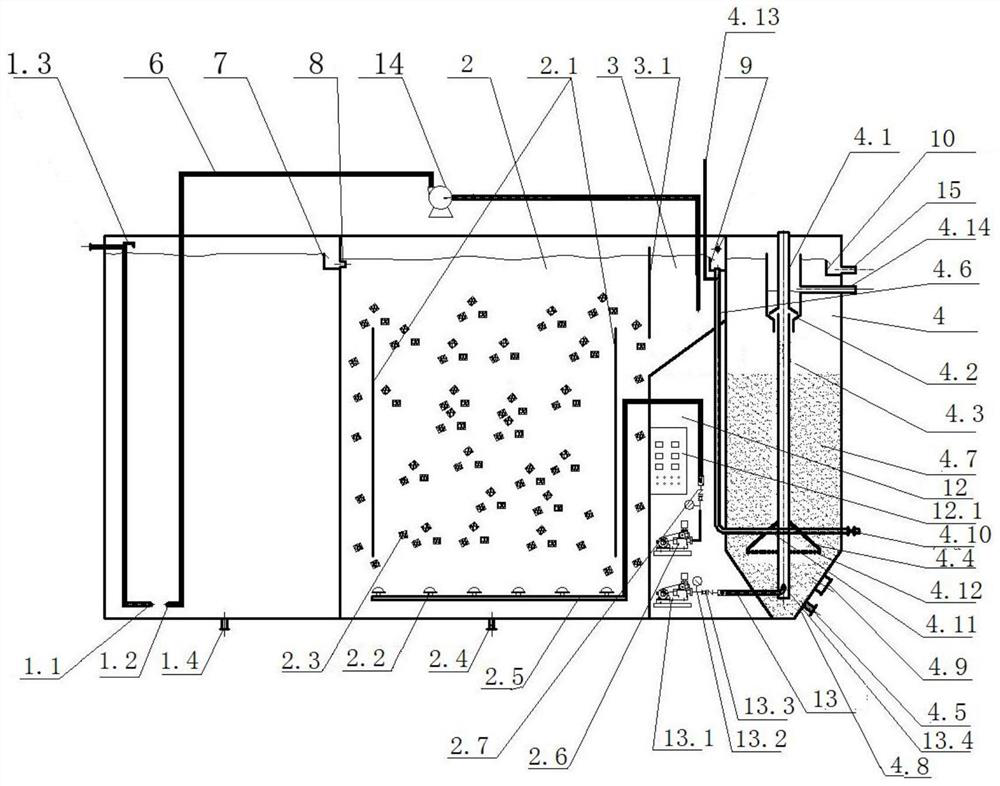

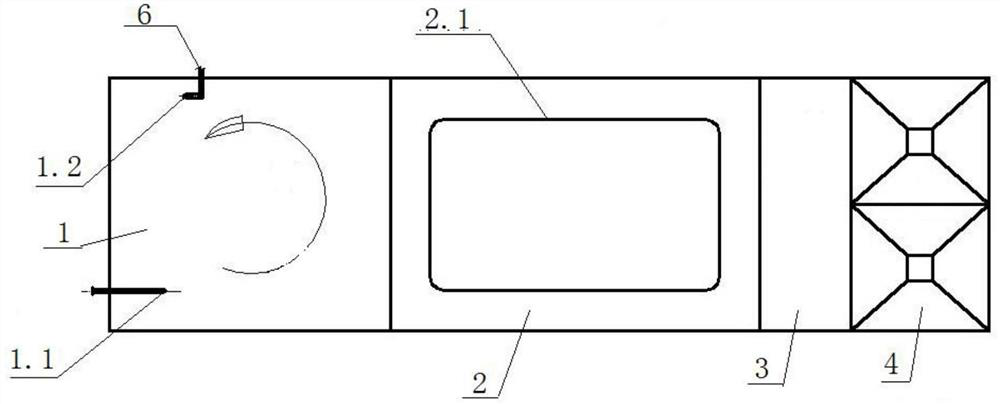

[0027] like figure 1 and figure 2 The low-concentration organic wastewater treatment system shown mainly includes anoxic pool 1, aerobic pool 2, packing separation pool 3, sand filter 4 and equipment room 12 connected in sequence, and equipment is arranged below the packing separation pool 3 Between 12, the lower part of the anoxic pool 1 has a water supply port, and the water supply port communicates with the water supply pipeline 5; an overflow port A7 is provided between the anoxic pool 1 and the aerobic pool 2; the aerobic pool 2 There is an aeration area inside, and the aerobic tank 2 is built with a certain proportion of porous biological filler 2.3, and microorganisms are attached to the surface and inner pores of the biological filler 2.3, and the microorganisms form a dense biofilm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com