Photogravure press

A gravure printing machine, unit type technology, applied in printing machines, printing, general parts of printing machinery, etc., can solve the problems of wasting energy, failing to achieve high efficiency, energy saving and environmental protection, and achieve water and energy saving, air pressure stability, and energy consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

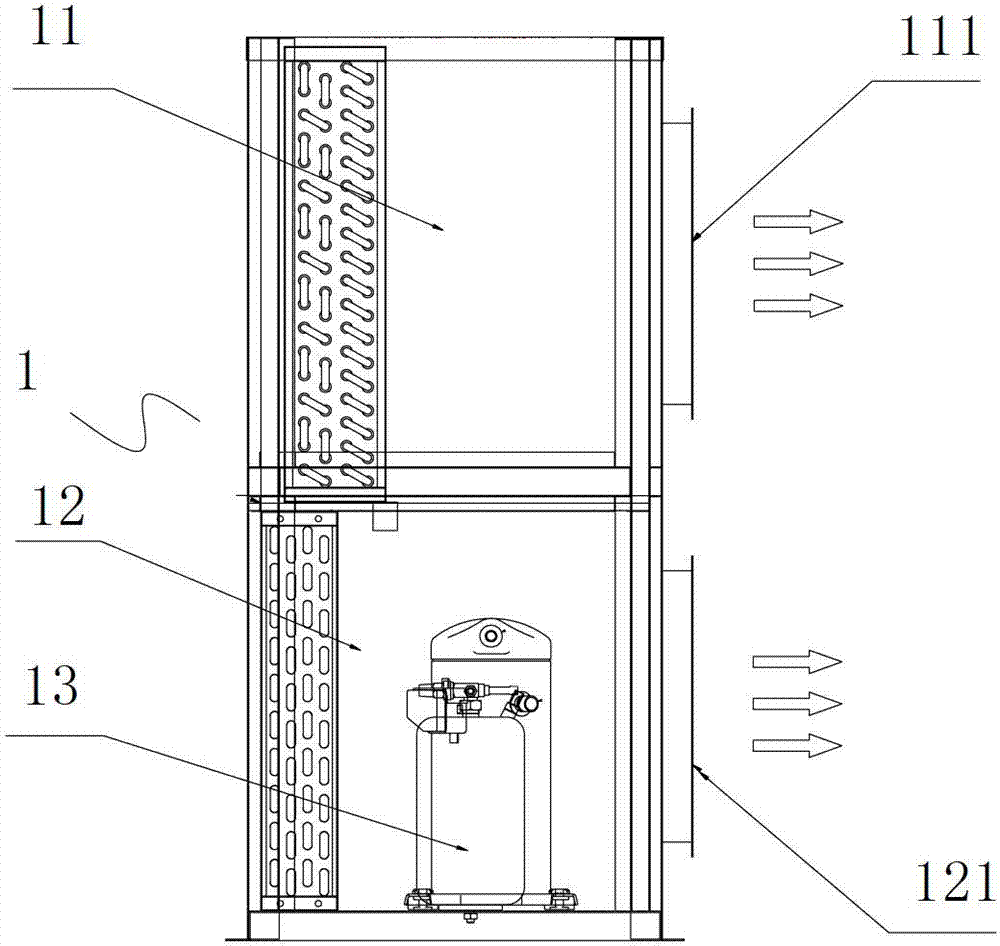

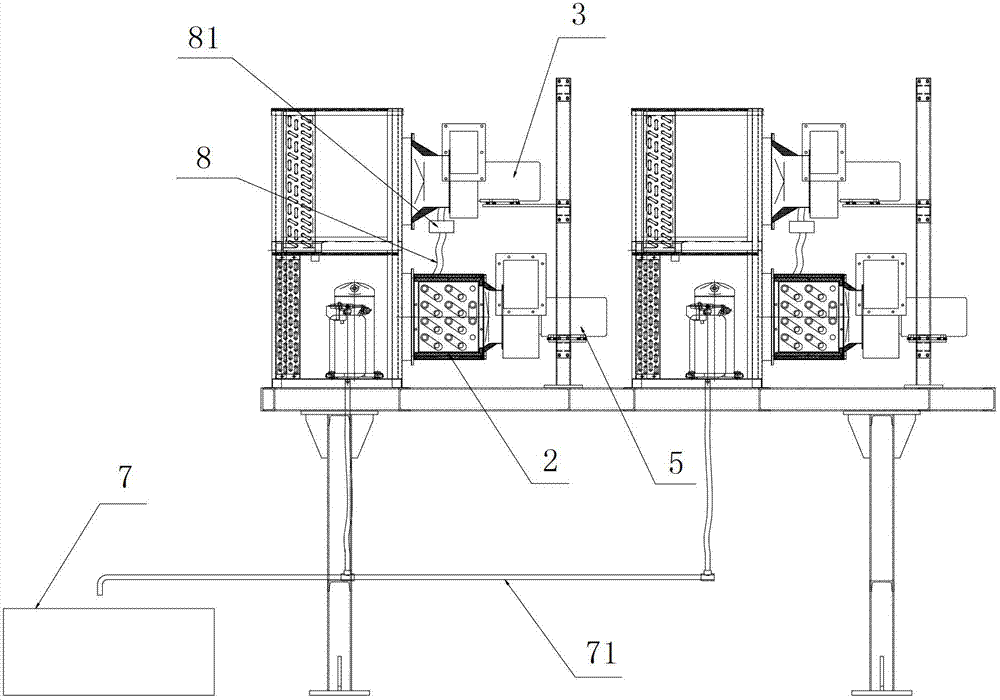

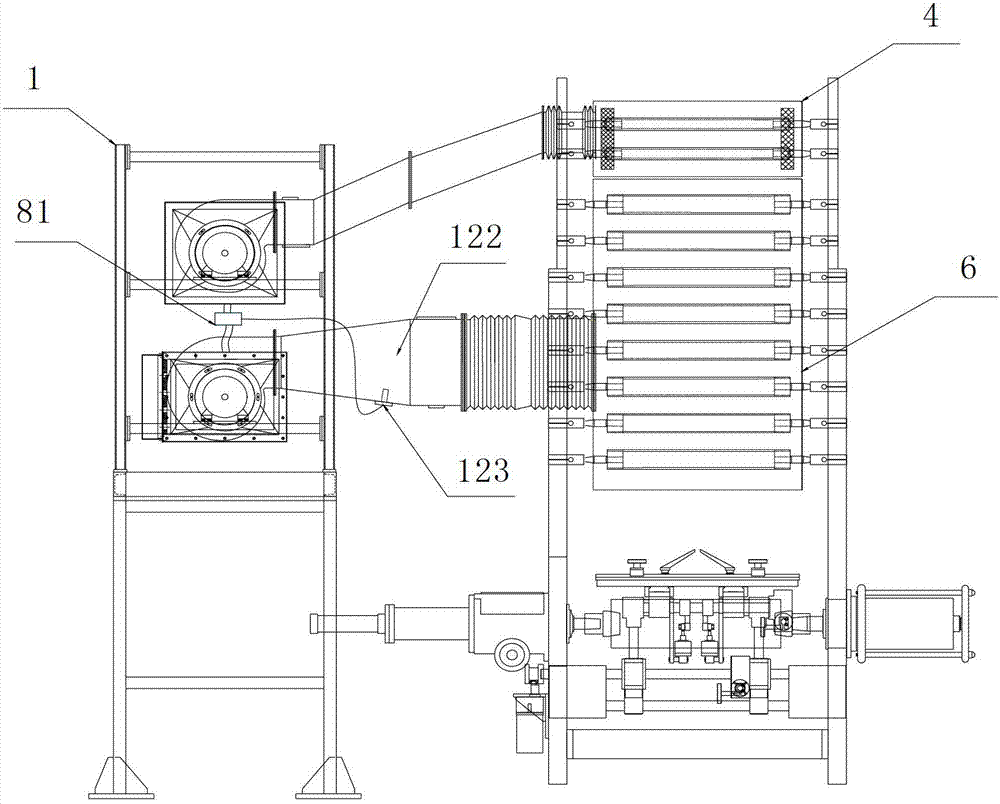

[0024] Such as figure 1 , 2 As shown, the gravure printing machine of this embodiment includes a unit-type gravure printing machine, and also includes a fully enclosed compression condenser 1 arranged between units of constant temperature required by each channel of the unit-type gravure printing machine. The fully enclosed compression condenser 1 is divided into upper and lower parts. The upper part is provided with a refrigerating part 11 and a cold air outlet 111, and the refrigerating part 11 communicates with the unit-type gravure printing machine through the cold air outlet 111; It communicates with the hot air box 5 of the unit-type gravure printing machine.

[0025] The compressor 13 is located in the heating part 12 of the fully enclosed compression condenser 1, which saves space and provides a small amount of heat energy. The refrigeration principle of the fully enclosed compression condenser 1 is the same as the existing conventional refrigeration principle. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com