All steel clothing

A technology for metal card clothing and card clothing steel wire, which is used in textiles and papermaking, fiber processing, deburring devices, etc., to achieve the effect of high fiber acceptance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

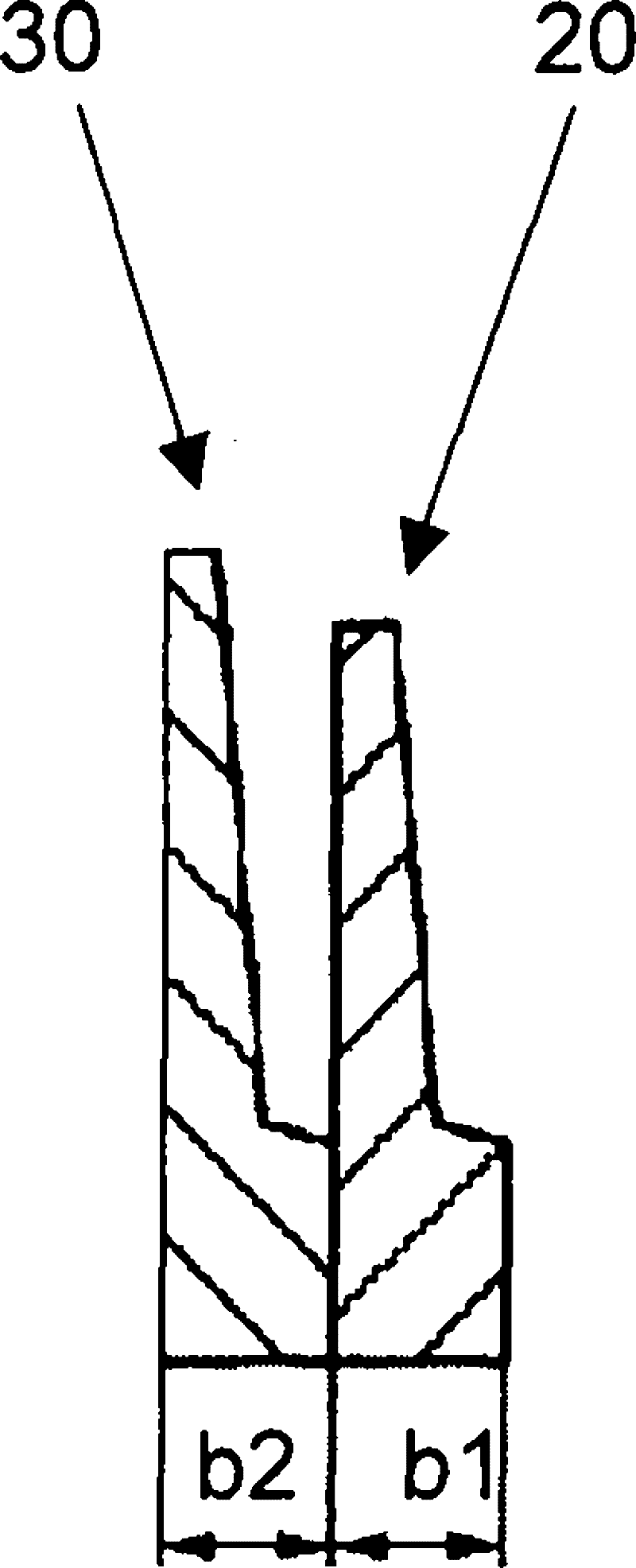

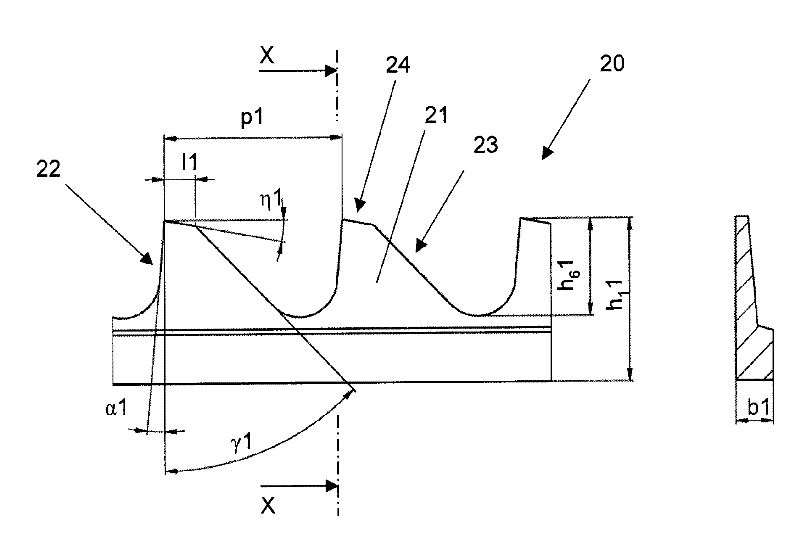

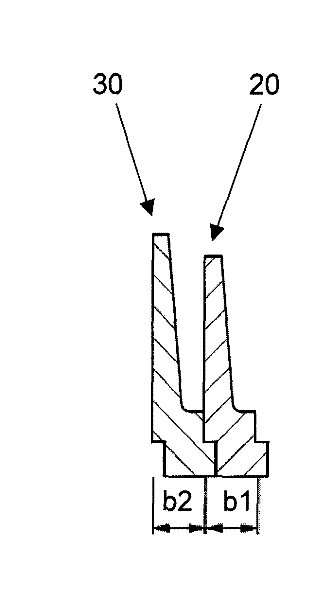

[0045] figure 1 A schematic diagram showing an embodiment of a first clothing wire 20 and a cross-sectional view at position X-X. Here a sawtooth wire is shown with teeth 21 having an overall height h of 4.5 mm 1 1 and 2.5mm tooth depth h 6 1. The teeth 21 of the clothing wire 20 are formed so as to create a face 24 . The face 24 is arranged to be inclined towards the rear side 23 of the tooth 21 so as to create a positive vertex angle η1. The front side 22 of the tooth 21 is inclined away from the rear side 23 of the tooth 21 so that a negative working angle α1 is formed. The teeth 21 of the first clothing wire 20 have a negative working angle α1 of 5° and a relief angle γ1 of 40°. The rib width b1 of the first clothing wire 20 was 1.0 mm. The tooth pitch p1 is 4.2 mm. The tooth 21 comprises a face 24 having a length l1 of 1.3 mm. The face 24 is slightly sloped with a positive posterior angle η1 of +5°. The first wire 20 is characterized by a negative working angle α...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com