Method for evaluating welding degree of hole type defect in forge piece

A technology of internal holes and evaluation methods, applied in the direction of testing the strength of materials by applying a stable bending force, to achieve the effect of convenient sampling, simple operation, and loose sample size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

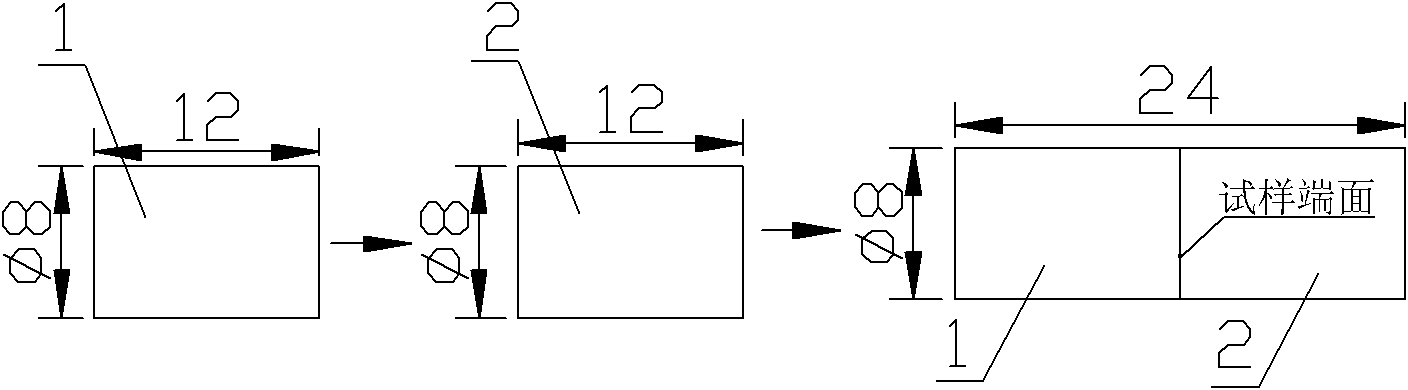

Embodiment 1

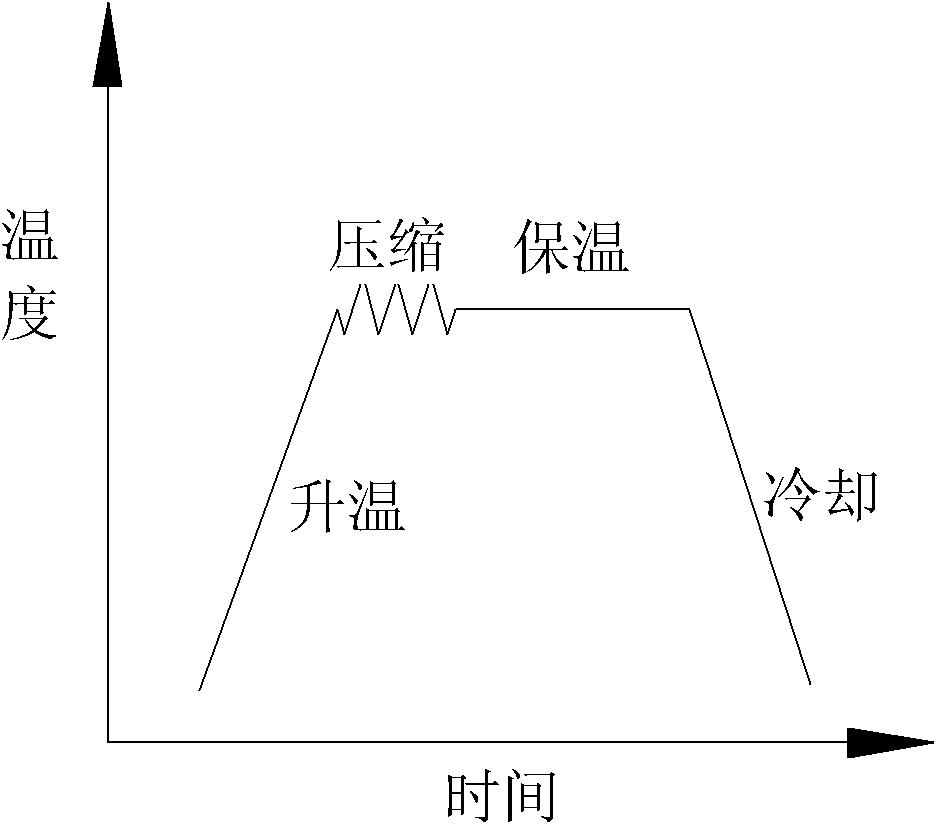

[0029] The experimental material 34MnV steel is processed into a small cylinder of Φ8×12mm, and the end surface roughness of the sample is Ra0.8. The surface of the processed sample was cleaned with acetone, and the sample docking experiment was carried out on a thermal simulation testing machine according to the preset deformation temperature of 1200 °C, holding time of 28 minutes and strain of 0.24. In the experiment, the heating rate was 5°C / s, the temperature soaking time was 5s, and the strain rate was 0.01s. -1 , the strain is 0.24, the pressure at both ends of the sample during the heat preservation stage is 5MPa, and the air cooling is completed after the heat preservation.

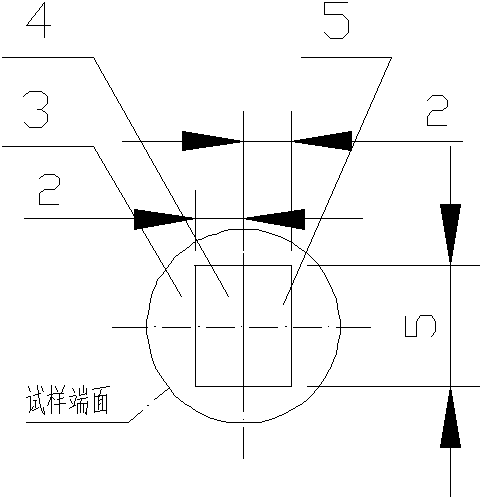

[0030] The butt joint samples after the experiment were cut into bending samples as shown in Figure 3, and a three-point bending test was carried out ( Figure 4 ). The bending strength of the obtained bending sample is 2170MPa, and the bending strength of the intact sample is 2600MPa, the weldi...

Embodiment 2

[0032] The experimental material 34MnV steel is processed into a small cylinder of Φ8×12mm, and the end surface roughness of the sample is Ra0.8. The surface of the processed sample was cleaned with acetone, and the sample docking experiment was carried out on a thermal simulation testing machine according to the preset deformation temperature of 1100 °C, holding time of 14 minutes and strain of 0.06. In the experiment, the heating rate was 5°C / s, the temperature soaking time was 5s, and the strain rate was 0.01s. -1 , the strain is 0.06, the pressure at both ends of the sample in the heat preservation stage is 5MPa, and the air cooling is completed after the heat preservation.

[0033] The butt joint samples after the experiment were cut into bending samples as shown in Figure 3, and a three-point bending test was carried out ( Figure 4 ). The bending strength of the obtained bending sample is 1950MPa, and the bending strength of the intact sample is 2600MPa, the welding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com