Substrate processing apparatus, wafer holder, and method of manufacturing semiconductor device

一种衬底处理装置、晶片支架的技术,应用在半导体/固态器件制造、电气元件、电路等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

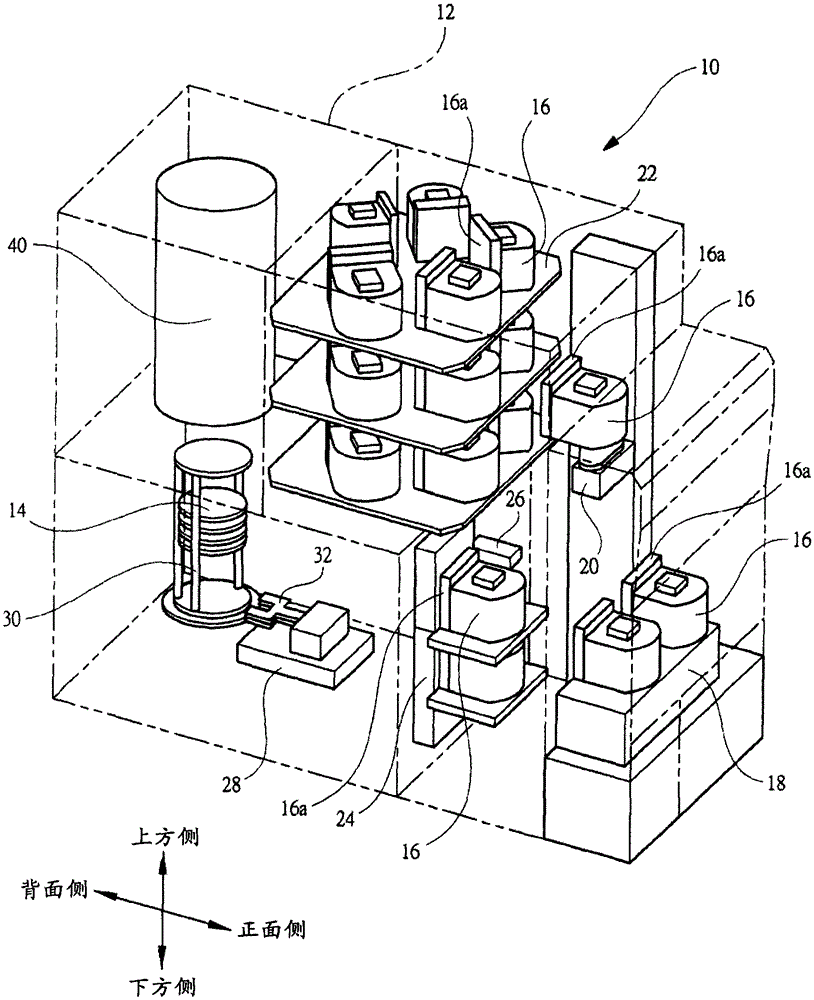

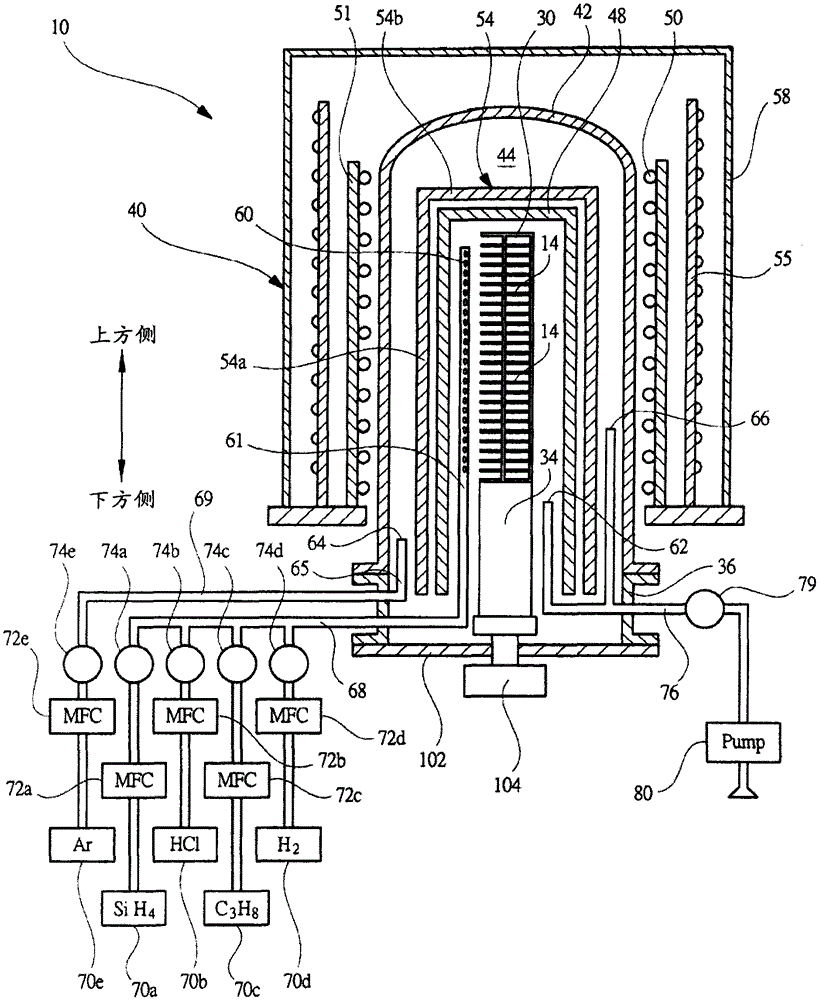

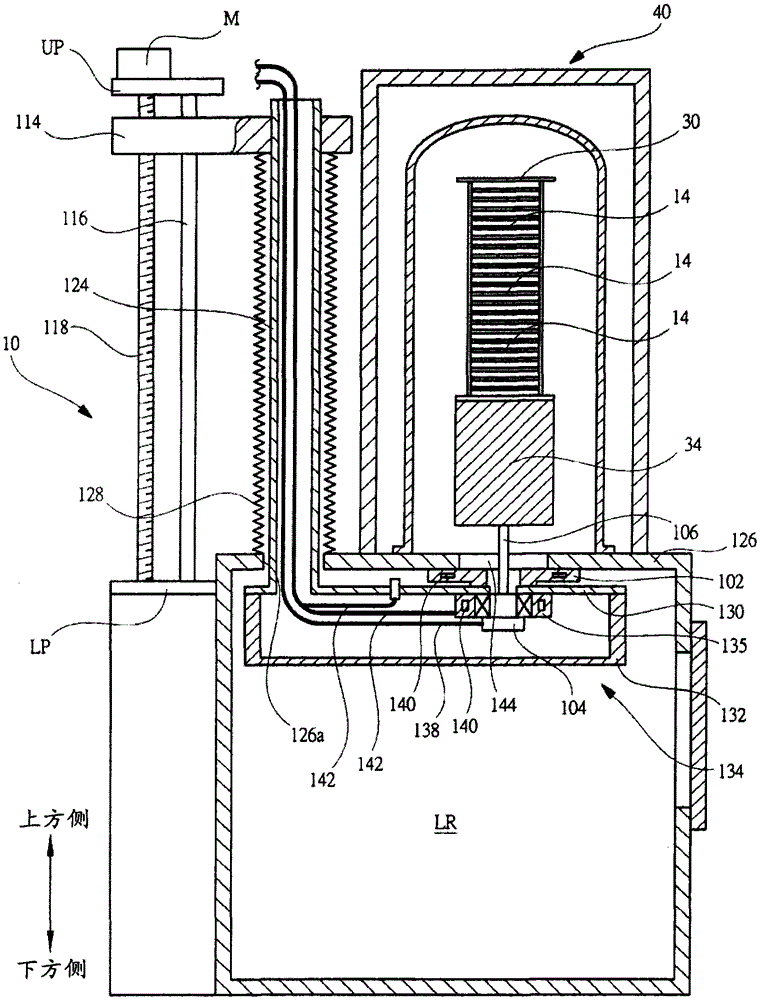

[0035] [First Embodiment] Hereinafter, a first embodiment of the present invention will be described in detail with reference to the drawings. In the following embodiments, a so-called batch type vertical SiC epitaxial growth apparatus that stacks SiC wafers in the height direction (vertical direction) is exemplified as a SiC epitaxial growth apparatus that is an example of a substrate processing apparatus. Thereby, the number of SiC wafers that can be processed at one time is increased and the throughput (manufacturing efficiency) is improved.

[0036] figure 1 It is a perspective view showing the outline of the substrate processing apparatus of the present invention. First, use figure 1 A substrate processing apparatus for forming an SiC epitaxial thin film and a method for manufacturing a substrate for forming an SiC epitaxial thin film, which is one of the manufacturing steps of a semiconductor device in one embodiment of the present invention, will be described.

[003...

no. 2 approach

[0122] [Second Embodiment] Hereinafter, a second embodiment of the present invention will be described in detail with reference to the drawings. In addition, about the same part as the said 1st Embodiment, the same code|symbol is attached|subjected, and the detailed description is abbreviate|omitted.

[0123] Figure 12 represent the wafer holder of the second embodiment and Figure 7 The corresponding stereogram, Figure 13 is for illustration Figure 12 An explanatory diagram of the reactive gas consumption portion of the wafer holder.

[0124] In the second embodiment, only the shape of the holder base 210 forming the wafer holder 200 is different from the first embodiment described above. That is, in the first embodiment, a pair of cutouts 112d are provided on the stand base 110 (refer to Figure 7 ), the outer peripheral side is non-circular, and in the second embodiment, each notch 112d is not provided on the stand base 210, but the outer peripheral side is circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com